Device for machining pipe fitting by using lathe

A technology for lathe processing and pipe fittings, applied in boring/drilling devices, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated clamping and high cost, and achieve the effects of reliable clamping, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

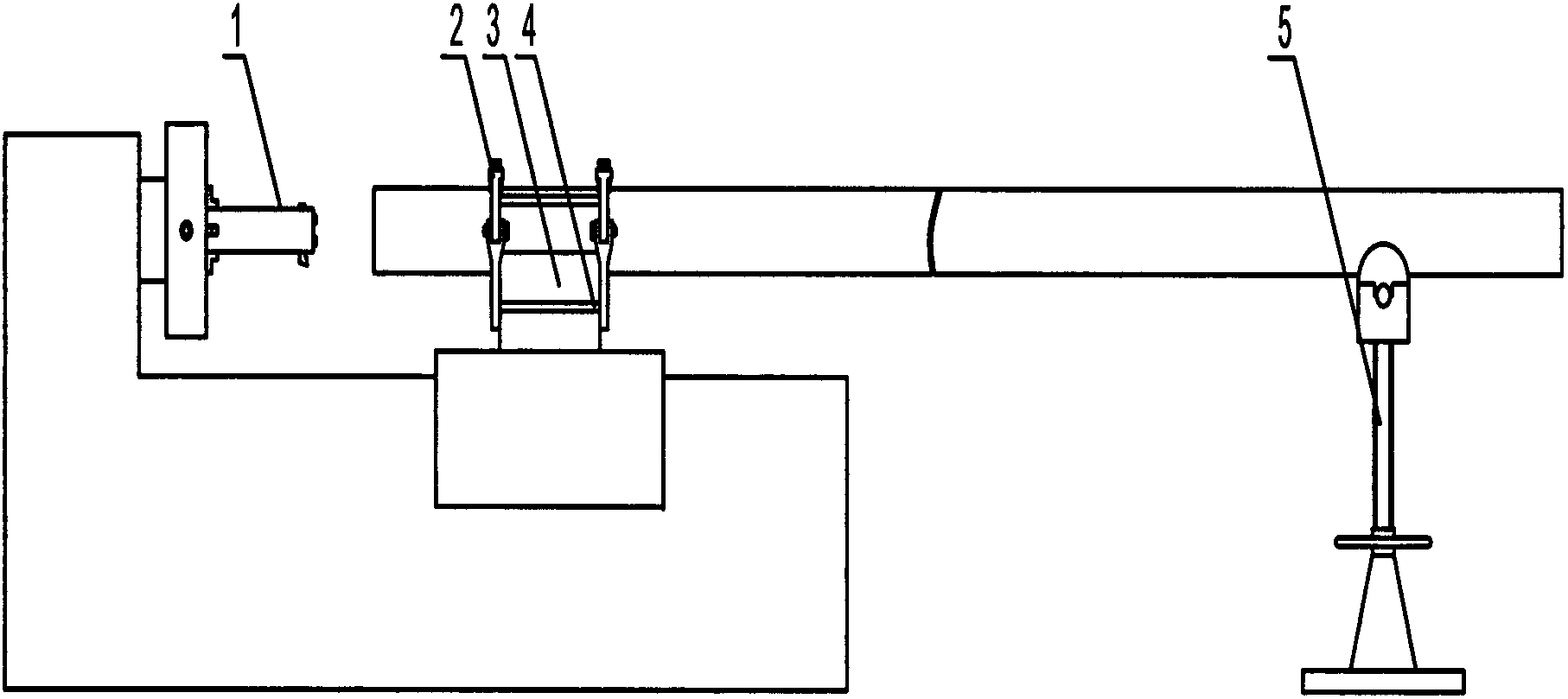

[0022] This embodiment is a device for processing pipe fittings using a C-630 lathe.

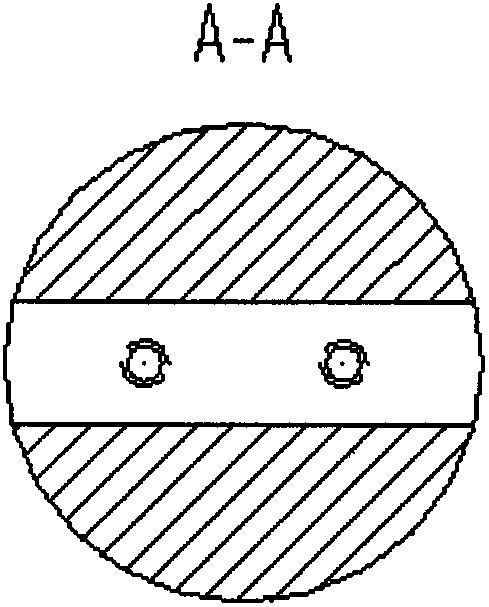

[0023] as attached figure 1 , This embodiment includes a tool holder 1, a clamp 2, a positioning block 3, a transition connecting plate 4, and a screw support frame 5. Wherein, one end of the tool rest 1 is clamped on the chuck of the main shaft of the lathe. The clamp 2 is fixed on the transition connection plate 4 through the connection plate located on the lower clamping body 7 . The transition connecting plate 4 is fixedly connected with the carriage in the lathe. The clamp 2 includes an upper clamping body 6 and a lower clamping body 7, the upper clamping body 6 is inserted into the splint at the two ends of the lower clamping body 7, and is connected by a shaft pin 10; the pressing pad 9 passes through Clamping bolts 8 are fixed on the inner surface of the upper clamping body 6 .

[0024] The tool holder 1 is a cylinder, and it is made of 45# steel bar stock quenched and tempered i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com