Aluminum strip drilling device for hollow glass molecular sieve filling machine

A drilling device and filling machine technology, applied in boring/drilling devices, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem that aluminum chips cannot be collected in time, the processing range is limited, and Pollution of the environment and other problems, to achieve the effect of improving drilling efficiency, accurate angle and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

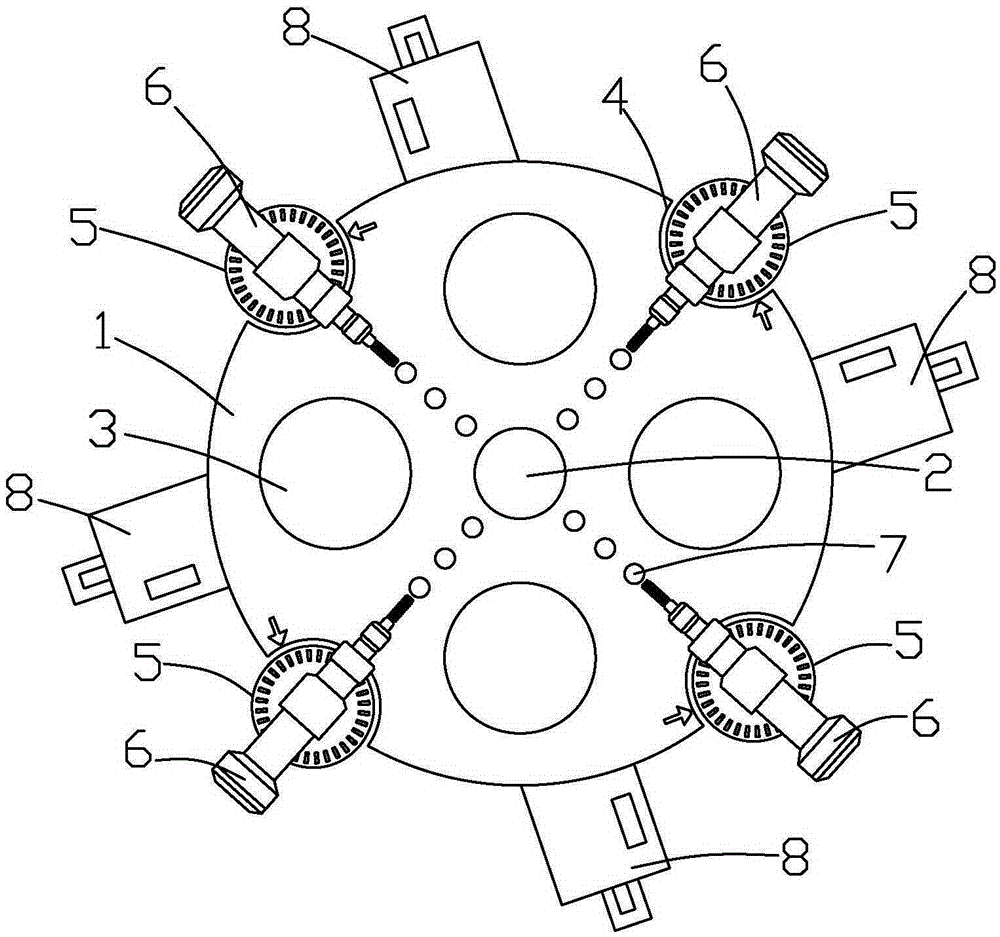

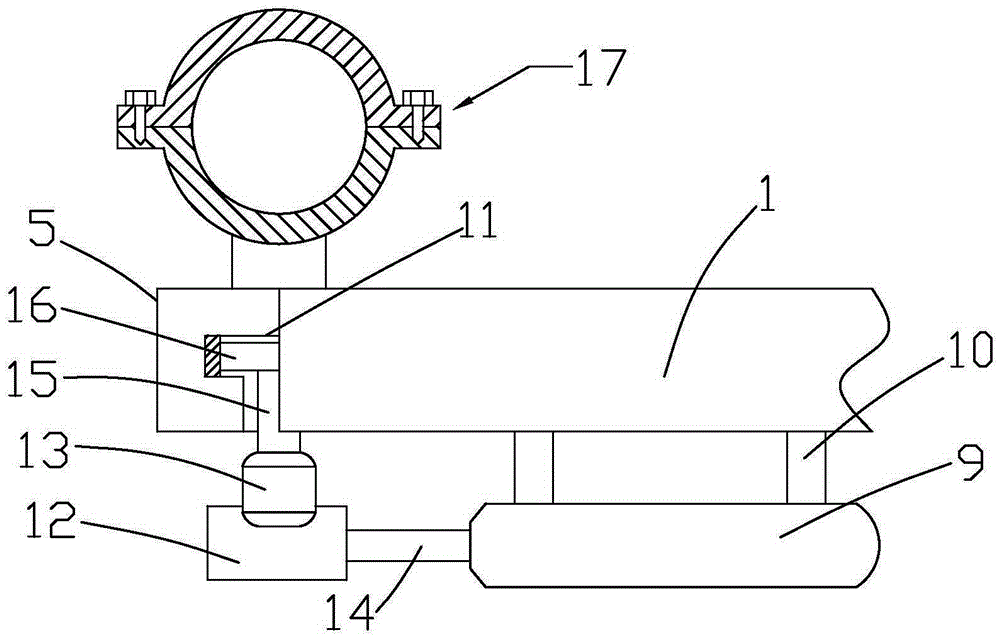

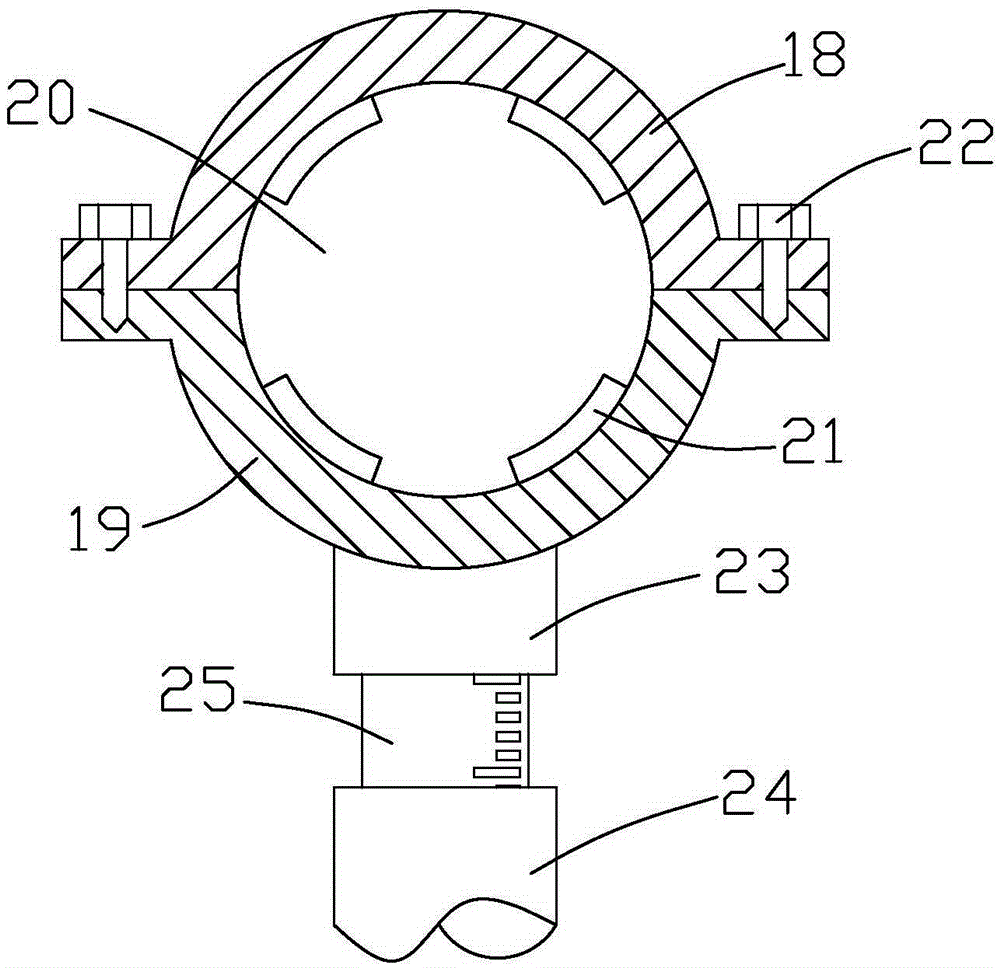

[0028] Such as Figure 1 to Figure 5 As shown, it is an aluminum bar drilling device for a hollow glass molecular sieve filling machine of the present invention. The aluminum bar drilling device includes a main turntable 1, a pneumatic drilling device 6 and a drill bit conversion frame 8. The center of the main turntable 1 is A drive shaft 2 is provided, and the main turntable 1 is connected to the molecular sieve filling machine through the drive shaft 2. At least four through holes 3 are evenly arranged around the drive shaft 2. The design of the through holes 3 can not only reduce the raw material consumption of the main turntable 1, but also Moreover, the overall weight of the main turntable 1 can be greatly reduced, making the main turntable 1 more flexible and stable when rotating, prolonging the service life of the drive shaft 2, reducing the accuracy error of the pneumatic drilling device 6 when rotating, and the main turntable 1 There are at least four semi-circular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com