Self-feed differential planet flat turn disc

A flat rotating disk and self-feeding technology, which is applied in the direction of drilling/drilling equipment, boring machine/drilling machine parts, boring/drilling devices, etc., can solve the problems of restricting the progress of machining technology, unsatisfactory accuracy, and large cost burden, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

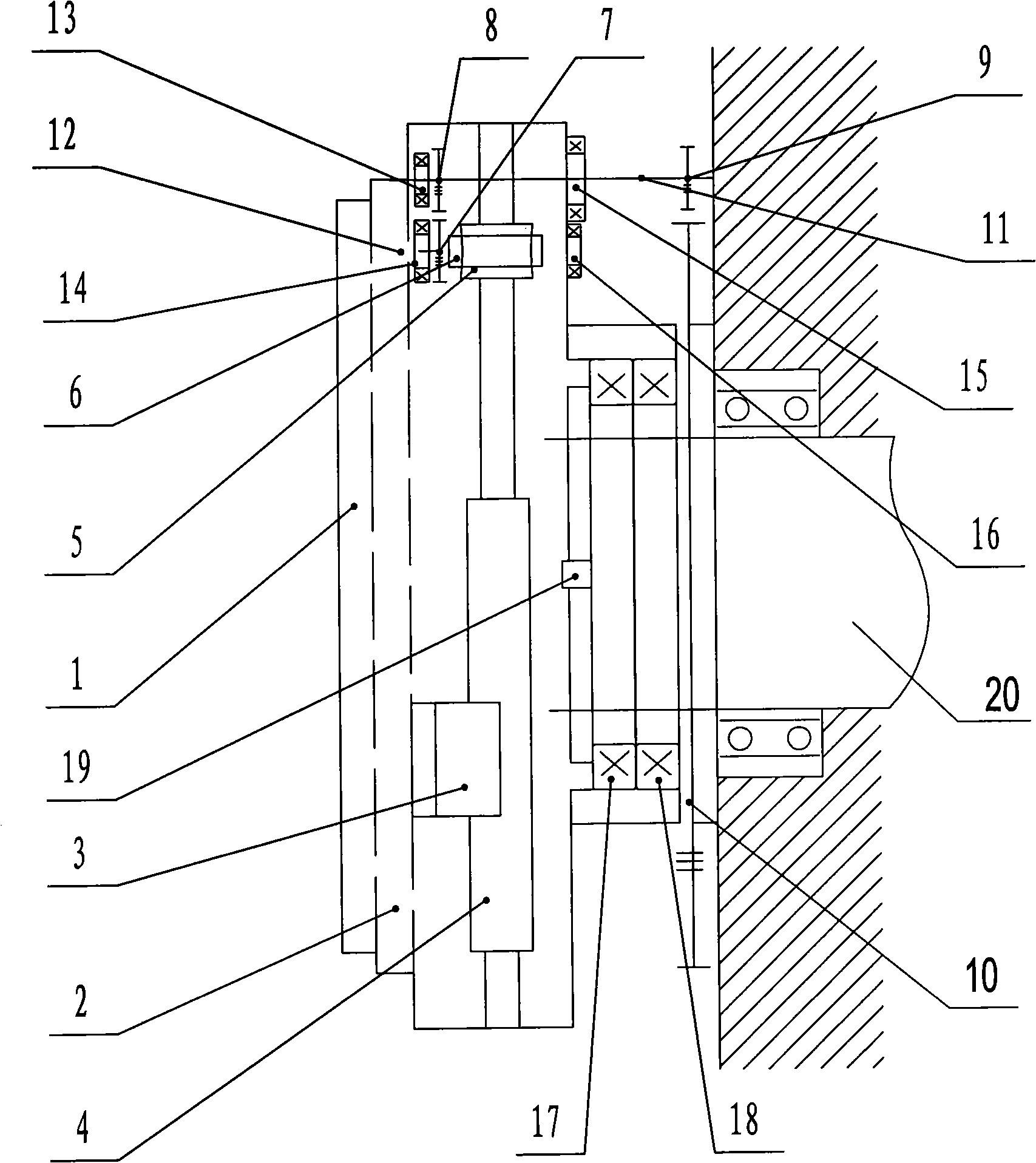

[0005] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0006] Given by the accompanying drawings, the structure of the present invention is that the boring and milling shaft 20 is connected with the flat rotating disk 1 by the end face key 19, and the flat rotating disk 1 and the boring and milling shaft 20 rotate simultaneously, and the fixed wheel gear 10 is housed outside the boring and milling shaft 20, It meshes with the planetary gear 9 on the flat rotating disk. The fixed wheel gear 10 has a tooth difference with the planetary gear. The rotation drives the planetary gear to rotate. The planetary gear is installed on the planetary driving gear shaft 11, and the driving gear 8 is installed on the coaxial. 8 is meshed with the driven gear 7 on the worm drive shaft 12. There is a coaxial worm 6 on the worm drive shaft. The coaxial worm 6 is connected to the worm wheel 5. The worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com