Boring machine for inner wall of drying drum

A technology of inner cylinder wall and boring machine, which is applied in the direction of boring/drilling, boring bar, boring/drilling device, etc., can solve the difficulty of boring the inner cylinder wall of the drying cylinder, increase the energy consumption of the lathe, and pull out The trend is getting bigger and other problems, so as to achieve the effect of prolonging the service life of the equipment, improving the boring accuracy and reducing the vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific examples.

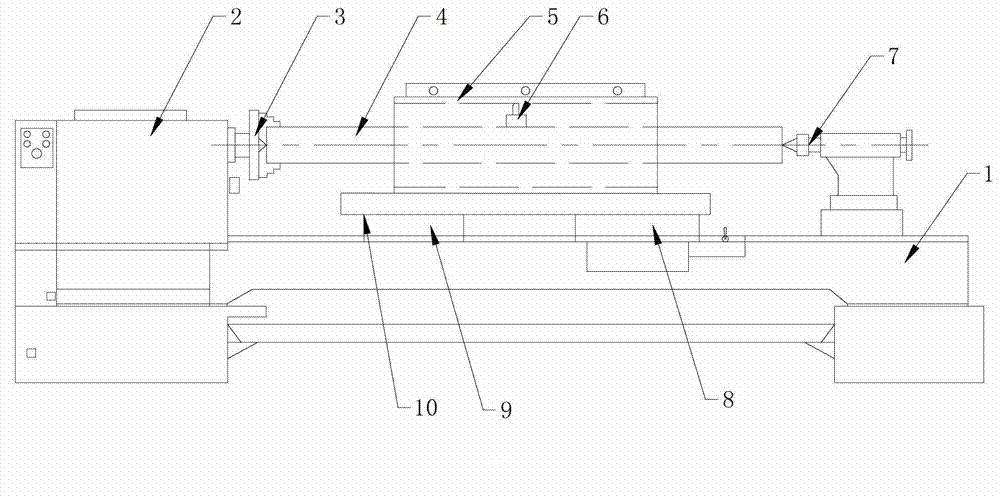

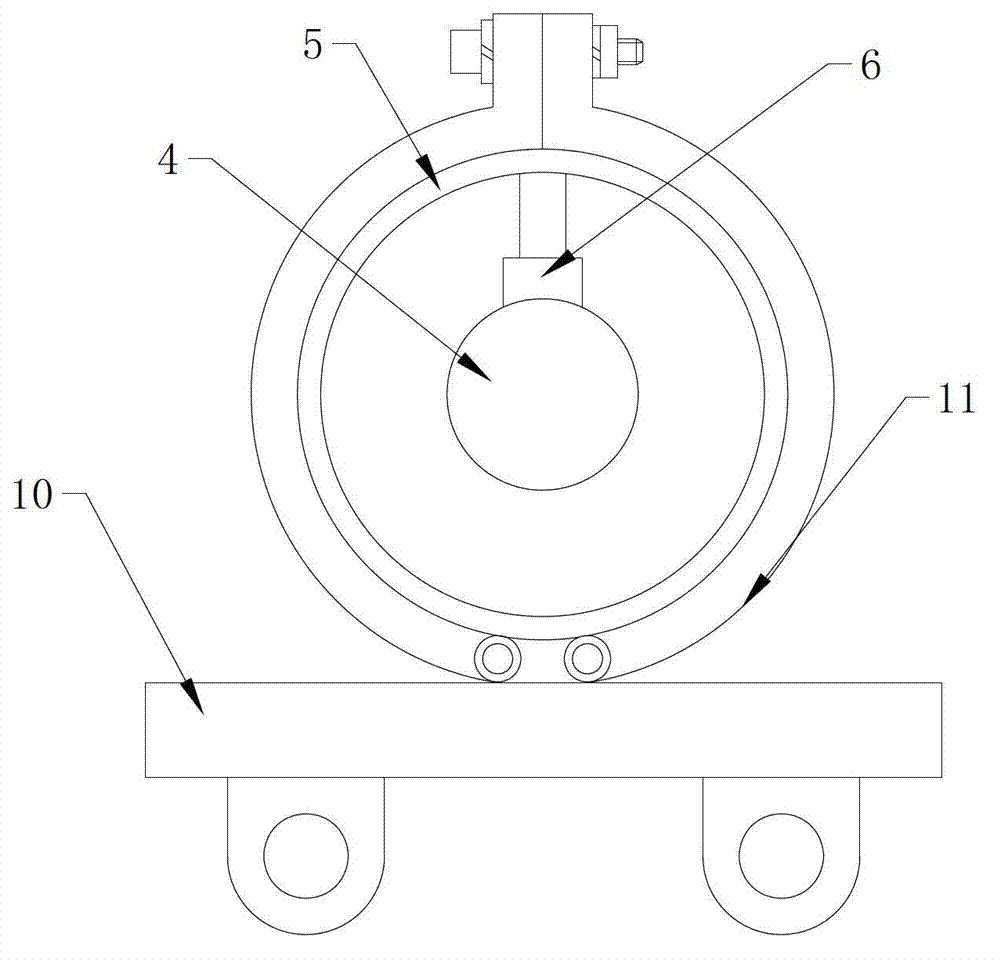

[0014] like figure 1 and figure 2 As shown, a boring machine for the inner cylinder wall of a drying cylinder 5 includes a base 1, a head 2 and a tailstock installed on the base 1, and a chuck driven by a main power device is installed on the head 2 3. The active power device is generally the headstock commonly used on ordinary lathes. The thimble 7 is installed on the tailstock. The thimble 7 is coaxially arranged with the chuck 3. An active support is installed slidingly between the head 2 and the tailstock. Seat 8 and driven support seat 9, the active support seat 8 is driven and slid by the auxiliary power device, generally speaking, a guide roller is installed between the headstock 2 and the tailstock, and its active support seat 8 and driven support seat 9 Installed on the guide roller, the active support seat 8 and the driven support seat 9 are equipped with a fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com