Device for quick detection of performance of rotating table of numerically-controlled machine tool

A technology of rotary table and detection device, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of poor static performance and reliability of CNC machine tool rotary table, achieve easy control, improve accuracy, Simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

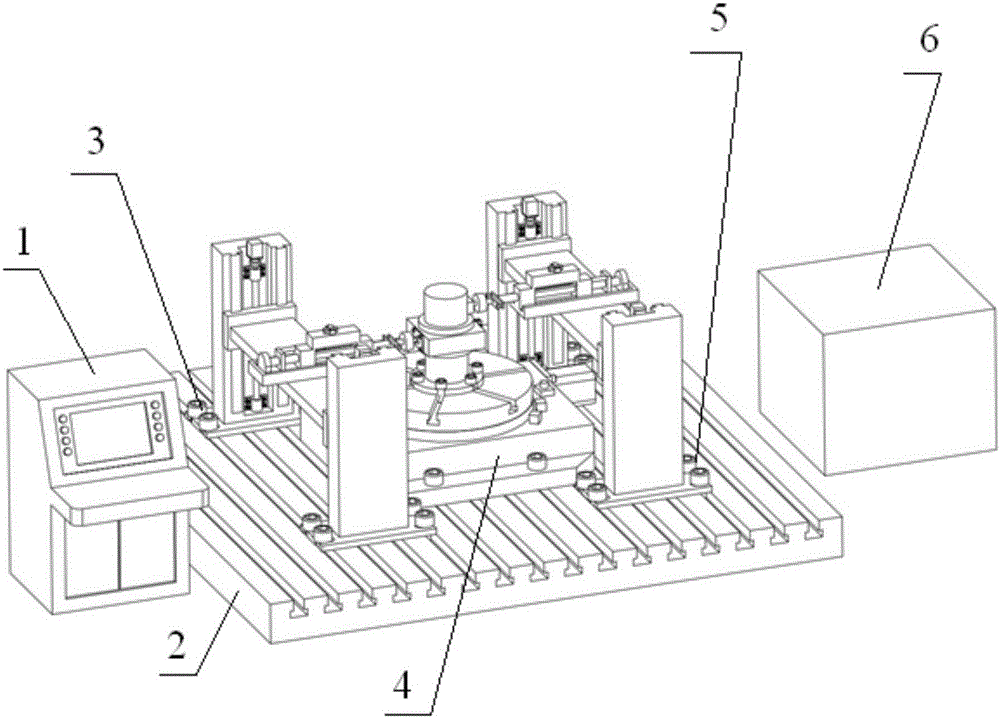

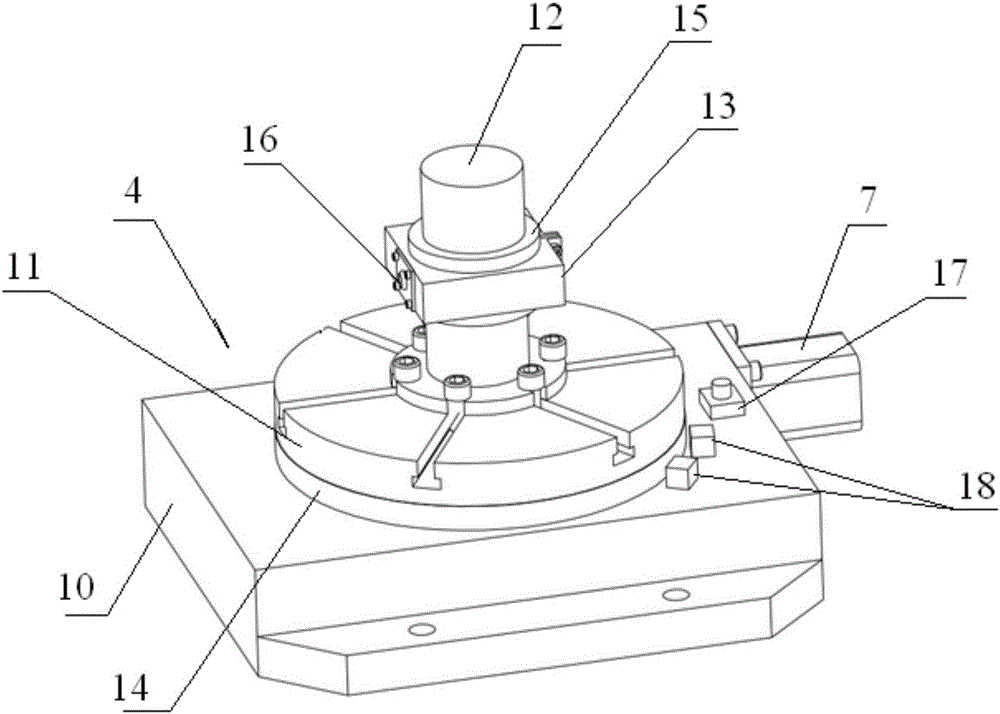

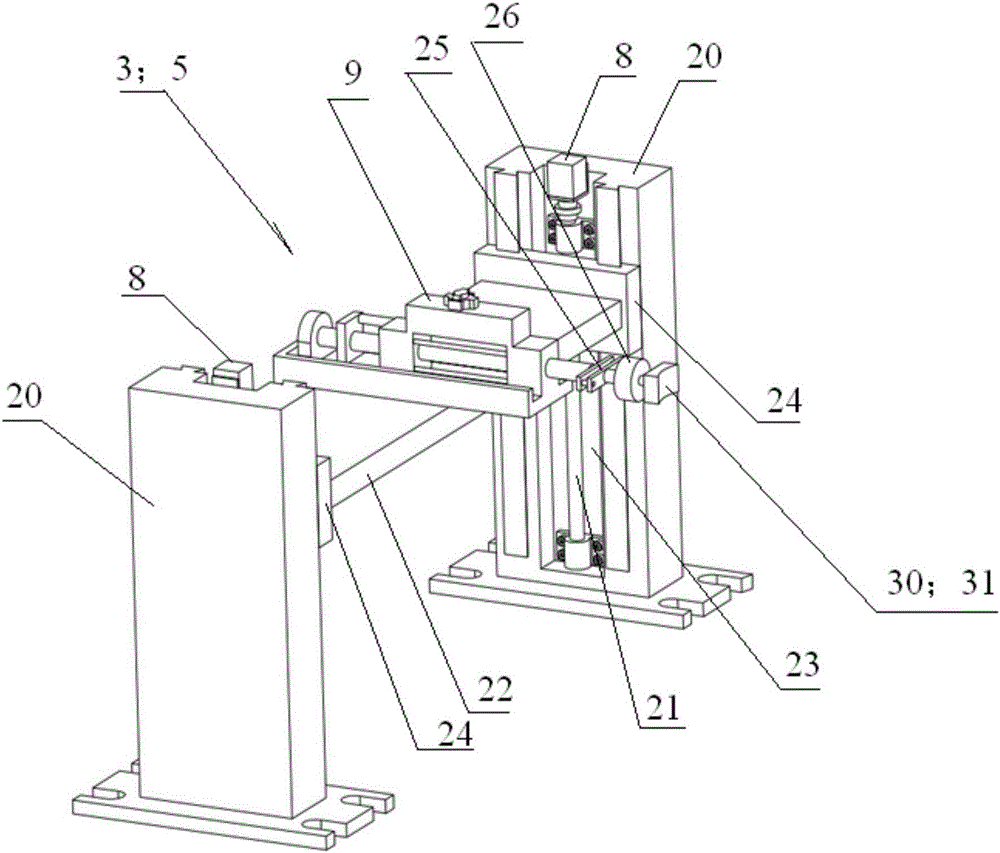

[0035] see figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0036] The fast detection device for the performance of the rotary table of a CNC machine tool provided by the present invention includes a control cabinet 1, a horizontal iron 2, a force loading device 3, a rotary table 4, a torque loading device 5 and an oil tank 6, wherein the force loading device 3, the rotary table 4 and the torque loading device 5 are installed on the horizontal iron 2, the force loading device 3 and the torque loading device 5 are arranged symmetrically on both sides of the rotary table 4, the control cabinet 1 and the fuel tank 6 are installed on both sides of the horizontal iron 2, and the rotary work A first servo motor 7 is provided on the platform 4, a second servo motor 8 and a servo hydraulic cylinder 9 are provided on the force loading device 3 and the torque loading device 5, and the control cabinet 1 controls the first servo motor 7 and the second servo motor 8 The oil tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com