Engine lathe deep hole working device

A technology of ordinary lathes and processing devices, which is applied in the direction of boring/drilling devices, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of high cost of heavy-duty deep hole drilling machines, inability to process deep holes, and large structural size, etc., and achieve reduction The effect of equipment purchase cost, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

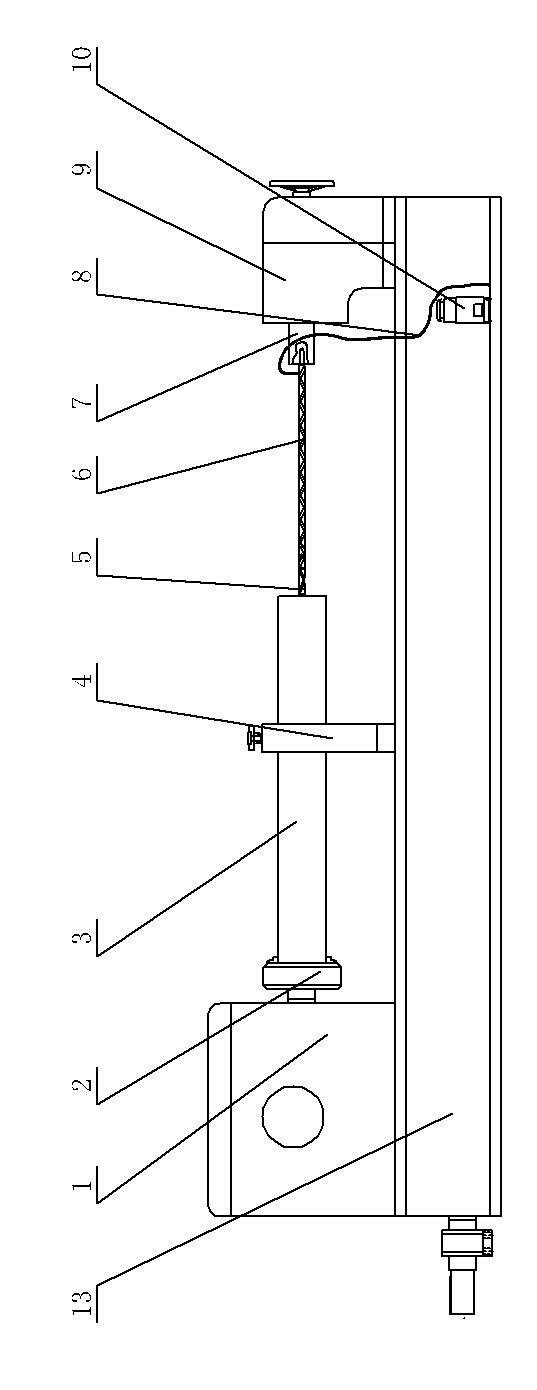

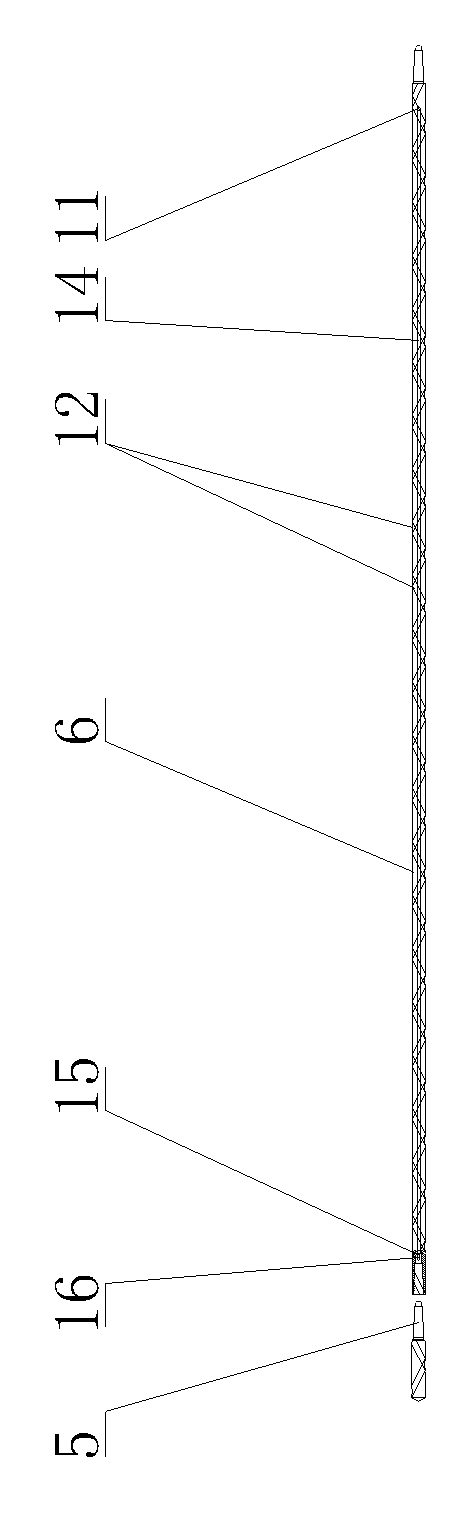

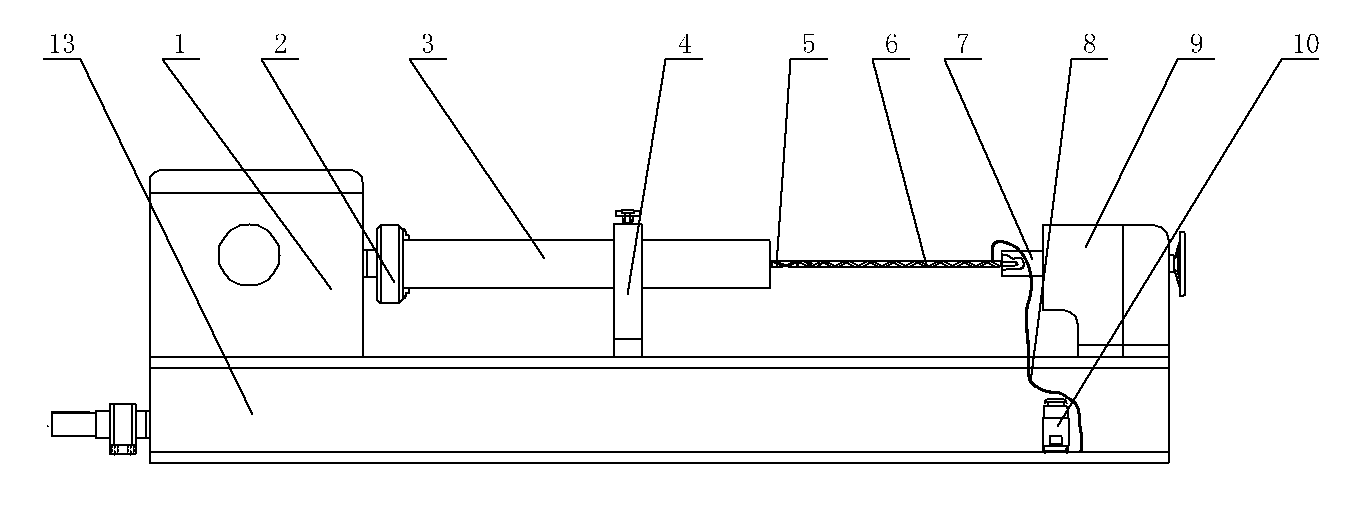

[0009] See figure 1 and figure 2 , the common lathe deep hole processing device of the present invention comprises lathe bed 13, bed 13 one end is equipped with headstock 1, the other end is installed with tailstock 9, bed 13 middle parts, headstock 1 and tailstock 9 are installed with Center frame 4, tailstock sleeve 7 are installed at the front end of tailstock 9, and extension drill rod 6 is installed in the tailstock sleeve 7, and twist drill bit 5 is connected and installed at the front end of extension drill rod 6. The surface of the extended drill rod 6 is provided with a chip removal groove 12 having the same lead as the twist drill bit 5; the extended drill rod 6 is provided with a through hole 14 along the length direction; a radial through hole 11 is provided at the end of the extended drill rod 6; the through hole 14 communicates with the radial through hole 11; the front end of the through hole 14 communicates with the twist drill removal groove 15 at the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com