Aluminum alloy inner hole ultra-precise machining tool and machining method

An aluminum alloy and inner hole technology, applied in metal processing equipment, manufacturing tools, drilling accessories, etc., can solve problems such as poor heat dissipation conditions, large tool vibration, and difficulty in chip discharge, so as to solve processing difficulties, optimize processing technology, Optimizing the effect of machining tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

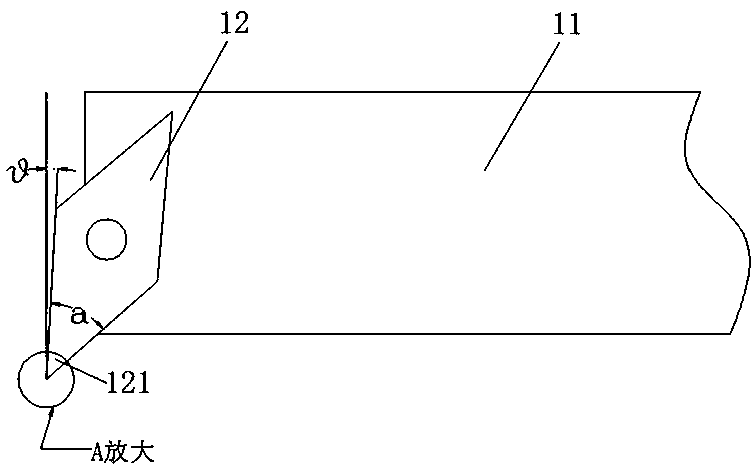

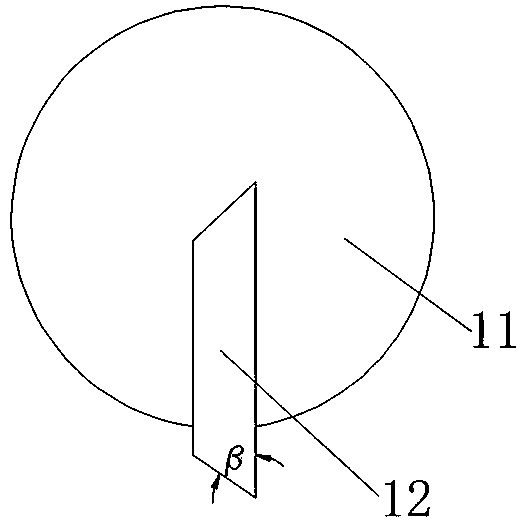

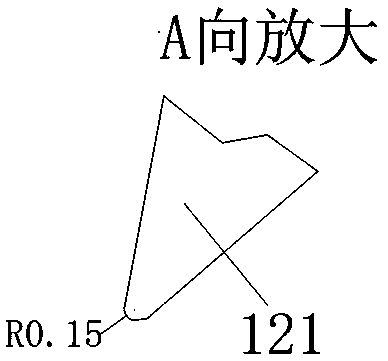

[0028] Embodiment 1: as Figure 1~Figure 3 As shown, a kind of aluminum alloy inner hole ultra-finishing tool 1 includes a handle 11 and a blade 12 fixedly connected to the front end of the handle. The handle 11 is a round rod structure made of cemented carbide, and its hardness is not Lower than HRC60~65; the blade 12 has a rhombus structure, and a wiper edge 121 is provided at the sharp edge of the rhombus structure. The side angle α of the wiper edge 121 is 85°, and the front angle β is 84° °, the rake angle θ is 7°, and the edge of the wiper blade 121 is a small arc structure with a radian of R0.15.

[0029] The hardness of the knife handle 11 is not lower than HRC60~65, and its shock resistance is good, and the knife handle 11 and the blade 12 are connected by welding, and its rigidity is good. The problems such as low processing accuracy, accelerated tool wear, and reduced processing efficiency.

[0030] Such as Figure 4 As shown, according to the above-mentioned alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com