Drilling device for end cover of motor

A technology of drilling device and motor end cover, applied in boring/drilling device, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the problems of complicated operation, high cost and large consumption, and achieve simple operation. , the effect of improving efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

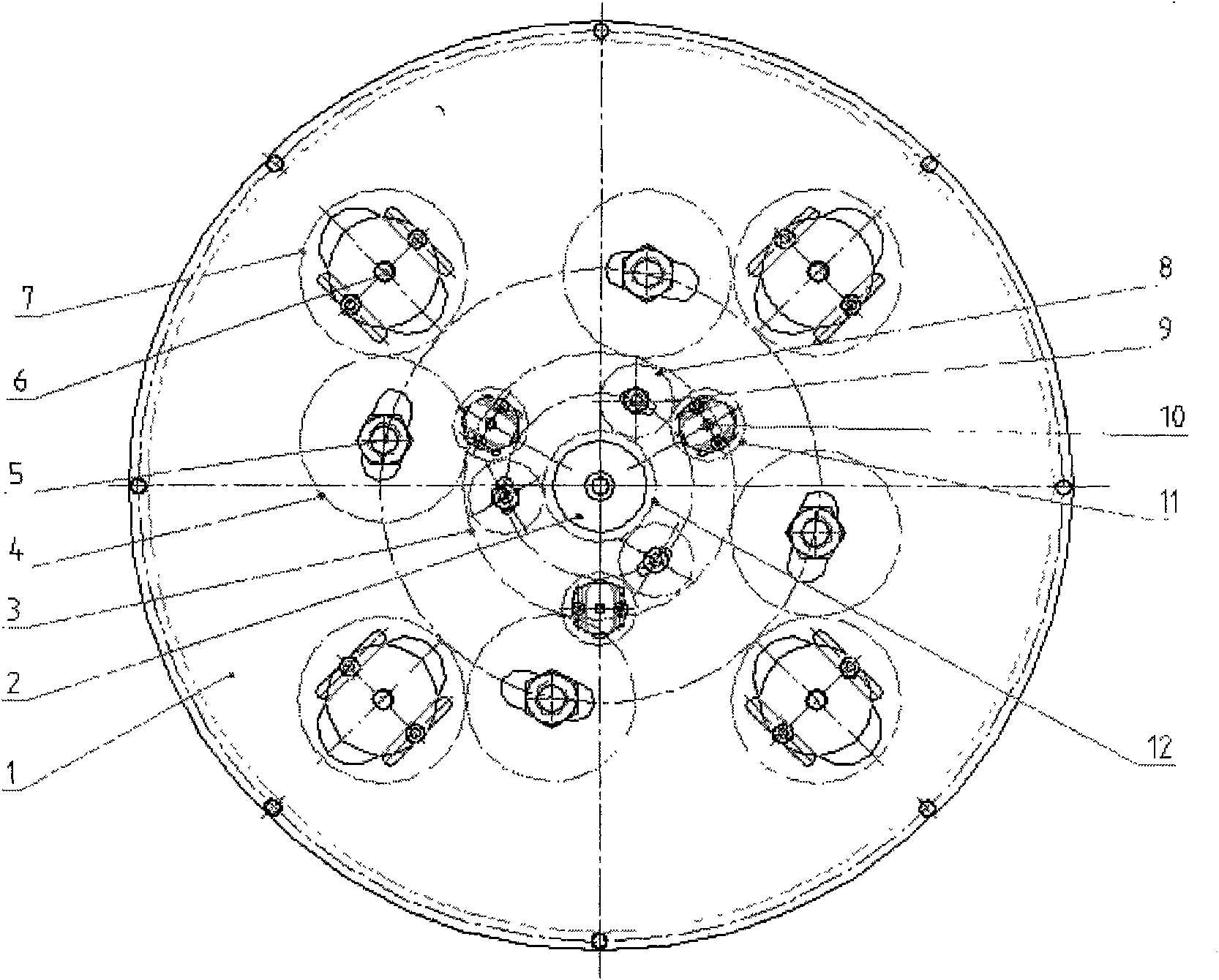

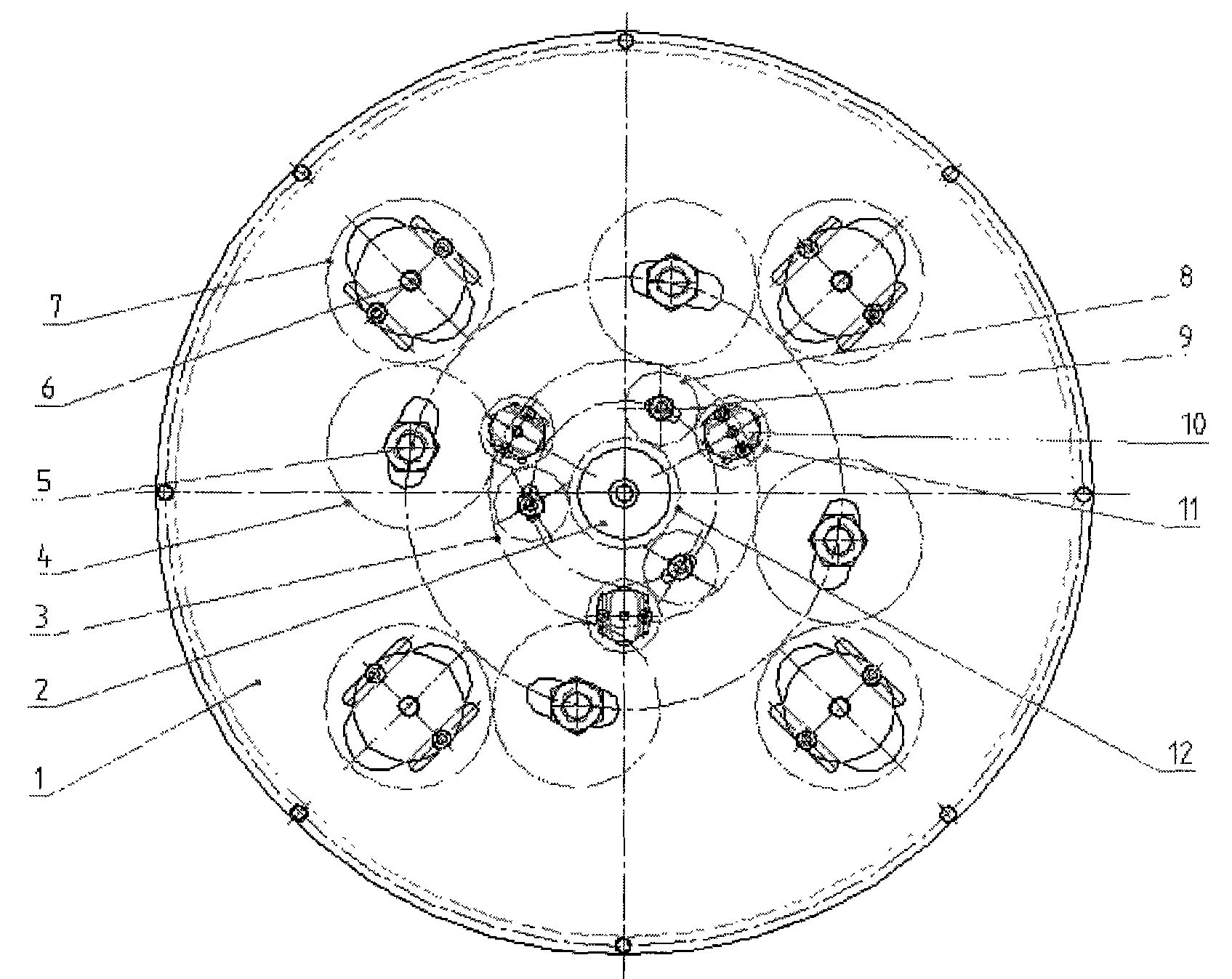

[0010] As shown in the accompanying drawings, a motor end cover drilling device is provided with a gearbox 1, a main gear shaft 2, a pinion gear shaft 6 and 10, a boundary wheel shaft 5 and 9, gears 3, 4, 7, 8, 11 and 12. It is characterized in that the device is powered by the movement of the main shaft of the ordinary lathe, that is, the main gear shaft 2 is put into the main shaft of the lathe, the drill bit sleeve is installed on the auxiliary gear shafts 6 and 10, and the gear on the big circle shaft 5 4 Mesh with the large gear 3 on the main gear shaft 2 and the gear 7 on the pinion shaft 6 at the same time, and the gear 8 on the small wheel shaft 9 simultaneously meshes with the pinion 12 on the main gear shaft 2 and the gear on the pinion shaft 10 11 meshing, the boundary wheel shafts 5, 9 and pinion shafts 6, 10 are made movable, as long as the position of the bou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com