Cylinder boring device and method for processing cylinder using the device

A cylinder and boring technology, which is applied to boring/drilling devices, metal processing equipment, parts of boring machines/drilling machines, etc., can solve problems such as uneven machining allowance of inner holes, weakening of cylinder strength, uneven wall thickness, etc. , to achieve the effect of improving rigidity, solving processing problems, and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

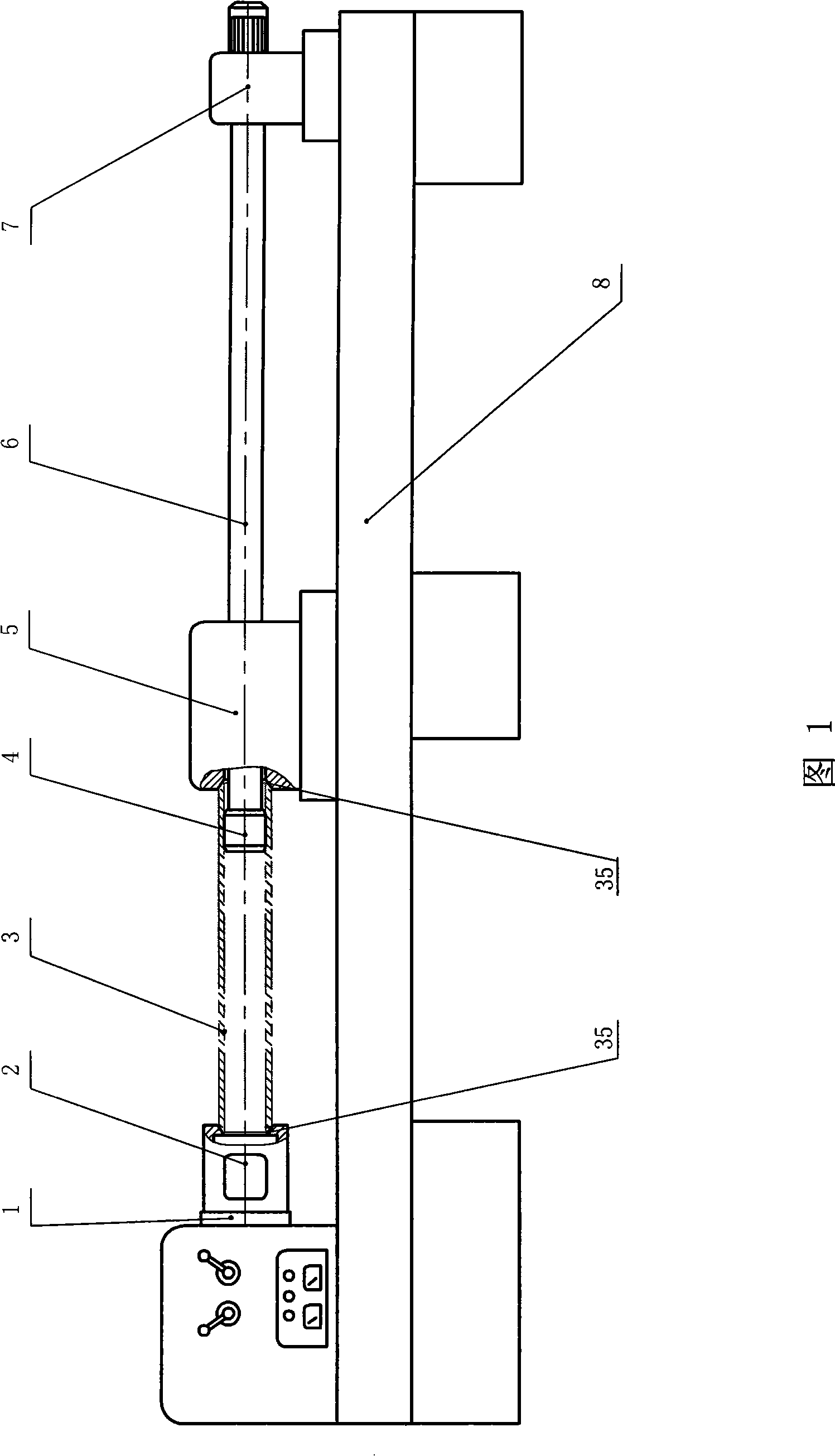

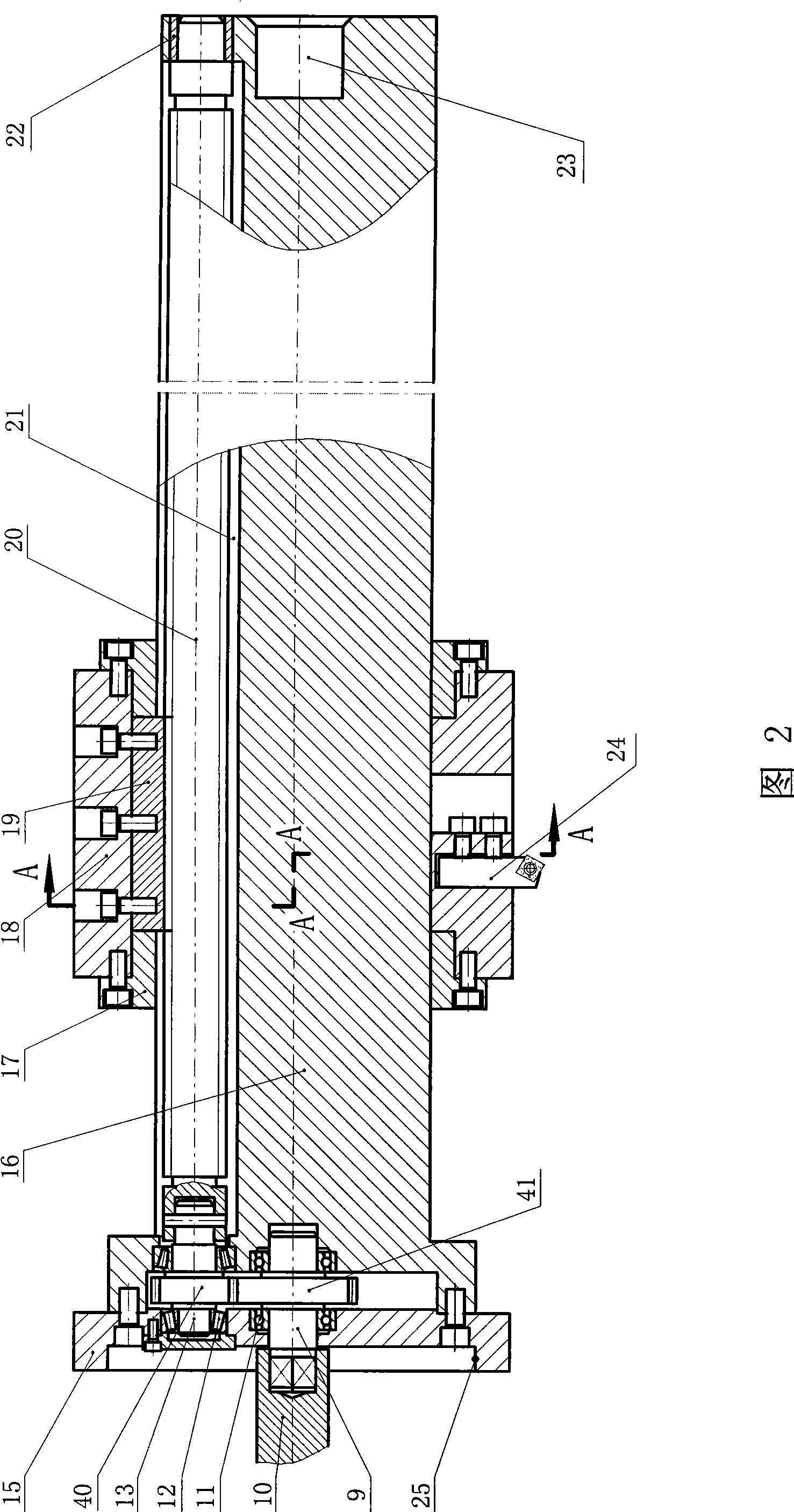

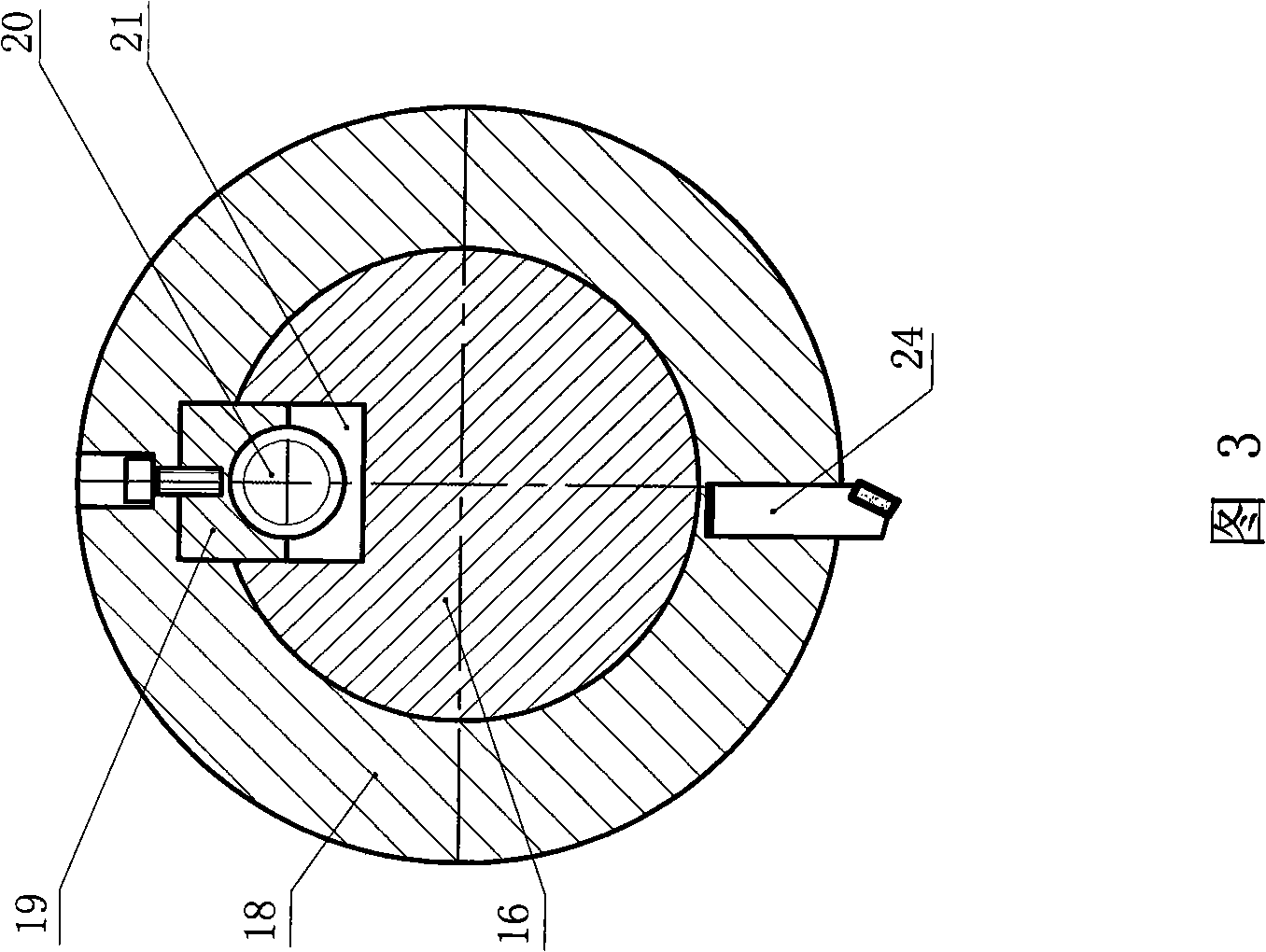

[0025] As shown in Figures 2 and 3, the cylinder boring device of the present invention processes a long groove 21 on the surface of the boring bar 16, and sets the lead screw 20 in the long groove 21, and the screw nut 19 is threadedly matched with the lead screw 20 Connect, screw nut 19 is fixedly connected with boring head 18 by screw, and boring tool 24 is installed on boring head 18, and guide ring 17 is fixed on the boring head 18, and its inner hole and boring bar 16 outer diameters slide fit. The front end of the boring bar 16 is fixedly connected with a positioning plate 15 by bolts, the end surface of the positioning plate 15 is perpendicular to the central axis of the boring bar 16, and the end surface of the positioning plate has a positioning hole, and the wall of the positioning hole is a positioning surface 25, which is coaxial with the boring bar 16 . The rear end of the lead screw 20 is hinged to the rear end of the boring bar 16 through a wear-resistant posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com