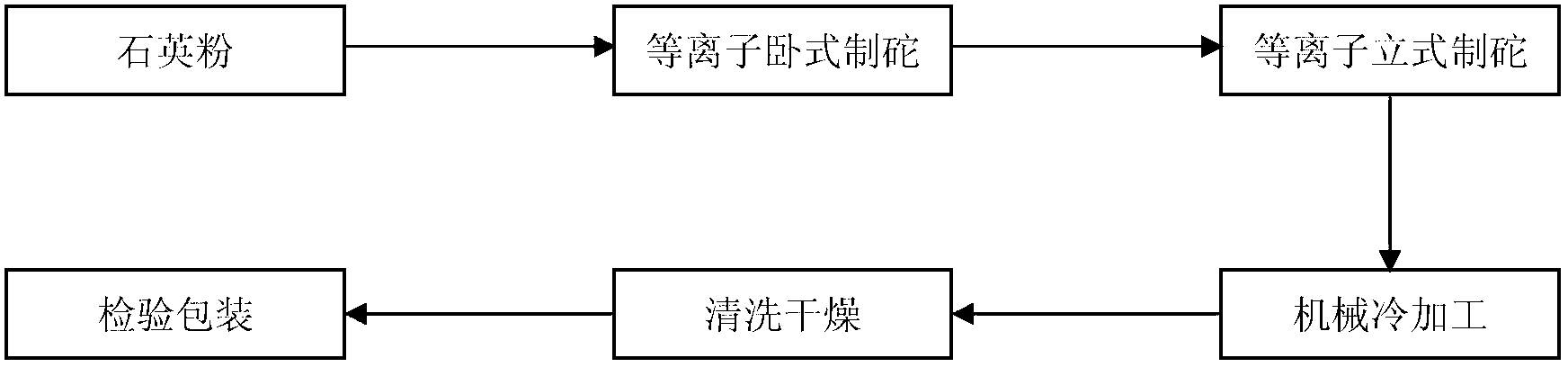

Method for preparing low-water-peak large-diameter optical fiber preform sleeve pipe

A technology of optical fiber preform and large diameter, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex process, shortage of helium resources, high production cost, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Dimensions of the quartz sleeve of the optical fiber preform with low water peak and large diameter:

[0045] The outer diameter is 200mm, the inner diameter is 43mm, and the length is 1500mm.

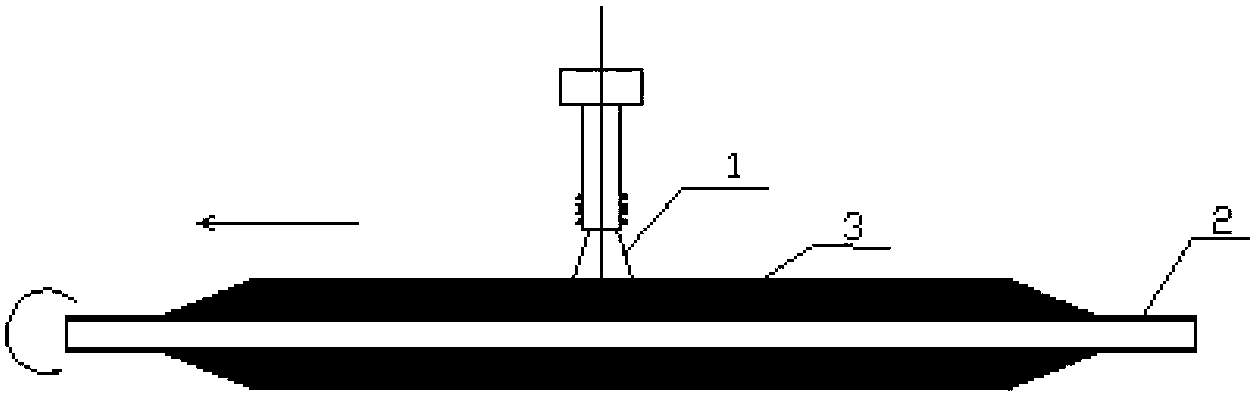

[0046] Step 1: First select high-purity quartz powder (total impurity content <30ppm), use plasma flame 1 as the heat source, and deposit quartz sand layer by layer on the outer circle of the central base tube 2 in the high-frequency plasma horizontal mound making machine , depositing 1.5 kilograms per hour, directly coating the fused quartz powder 3 on the central base pipe 2, depositing for 40 hours to form a hollow quartz wool mound 5 with a diameter of 150-160 mm;

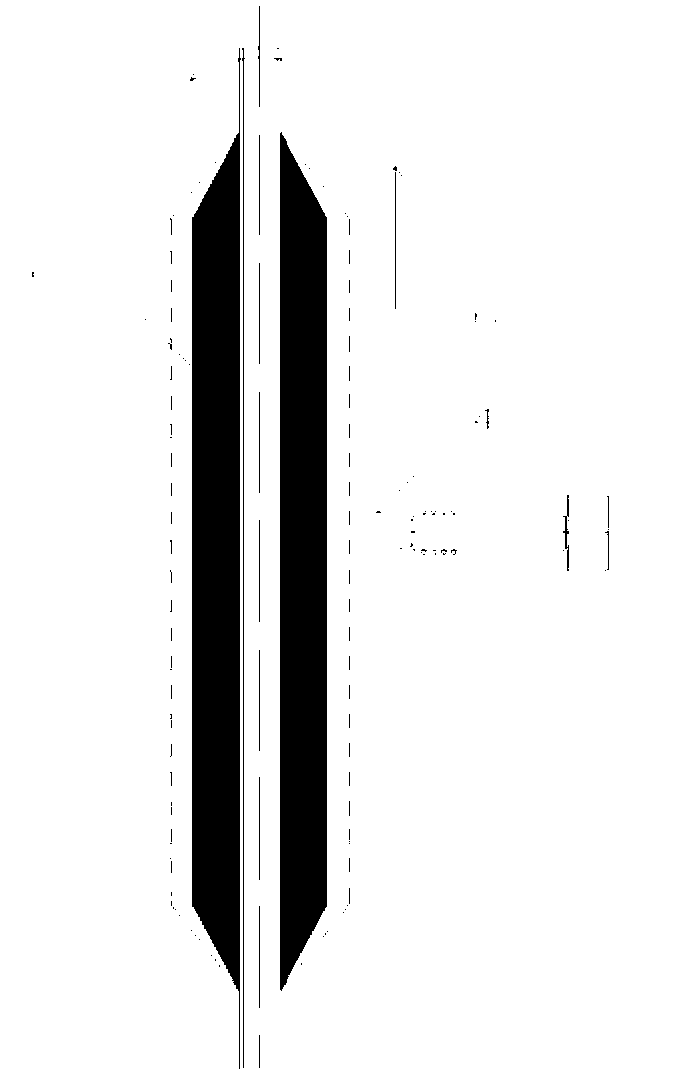

[0047] The second step: select high-purity quartz powder, continue to use the ion flame 4 as the heat source, deposit quartz sand layer by layer on the outer circle of the quartz wool mound 5 in the high-frequency plasma vertical mound making machine, deposit 1.0 kg per hour to melt The quartz powd...

Embodiment 2

[0051] Embodiment 2: Dimensions of the quartz sleeve of the optical fiber preform with low water peak and large diameter:

[0052] The outer diameter is 260mm, the inner diameter is 43mm, and the length is 1650mm.

[0053] Step 1: First select high-purity quartz powder (total impurity content <30ppm), use plasma flame 1 as the heat source, and deposit quartz sand layer by layer on the outer circle of the central base tube 2 in the high-frequency plasma horizontal mound making machine , depositing 1.4 kilograms per hour, directly coating the fused quartz powder 3 on the central base pipe 2, depositing for 44 hours to form a quartz wool mound 5 with a diameter of 150-160mm;

[0054] The second step: select high-purity quartz powder, continue to use the ion flame 4 as the heat source, and deposit quartz sand layer by layer on the outer circle of the hollow quartz wool mound 5 in the high-frequency plasma vertical mound making machine, depositing 1.2 kg per hour. The molten quart...

Embodiment 3

[0058] Example 3: Dimensions of the quartz sleeve of the optical fiber preform with low water peak and large diameter:

[0059] The outer diameter is 310mm, the inner diameter is 43mm, and the length is 2000mm.

[0060] Step 1: First select high-purity quartz powder (total impurity content <30ppm), use plasma flame 1 as the heat source, and deposit quartz sand layer by layer on the outer circle of the central base tube 2 in the high-frequency plasma horizontal mound making machine , depositing 1.4 kilograms per hour, directly coating the fused quartz powder 3 on the central base pipe 2, depositing for 52 hours to form a hollow quartz wool mound 5 with a diameter of 150-160 mm;

[0061] The second step: select high-purity quartz powder, continue to use the ion flame 4 as the heat source, and deposit quartz sand layer by layer on the outer circle of the quartz wool mound 5 in the high-frequency plasma vertical mound making machine, depositing 1.4 kg per hour to melt The quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com