Method for determining compression parameters of modular satellite

A definite method and modular technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to calculate, delay the development progress, and insufficient design rigidity, so as to improve the design level and clear the design process , the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

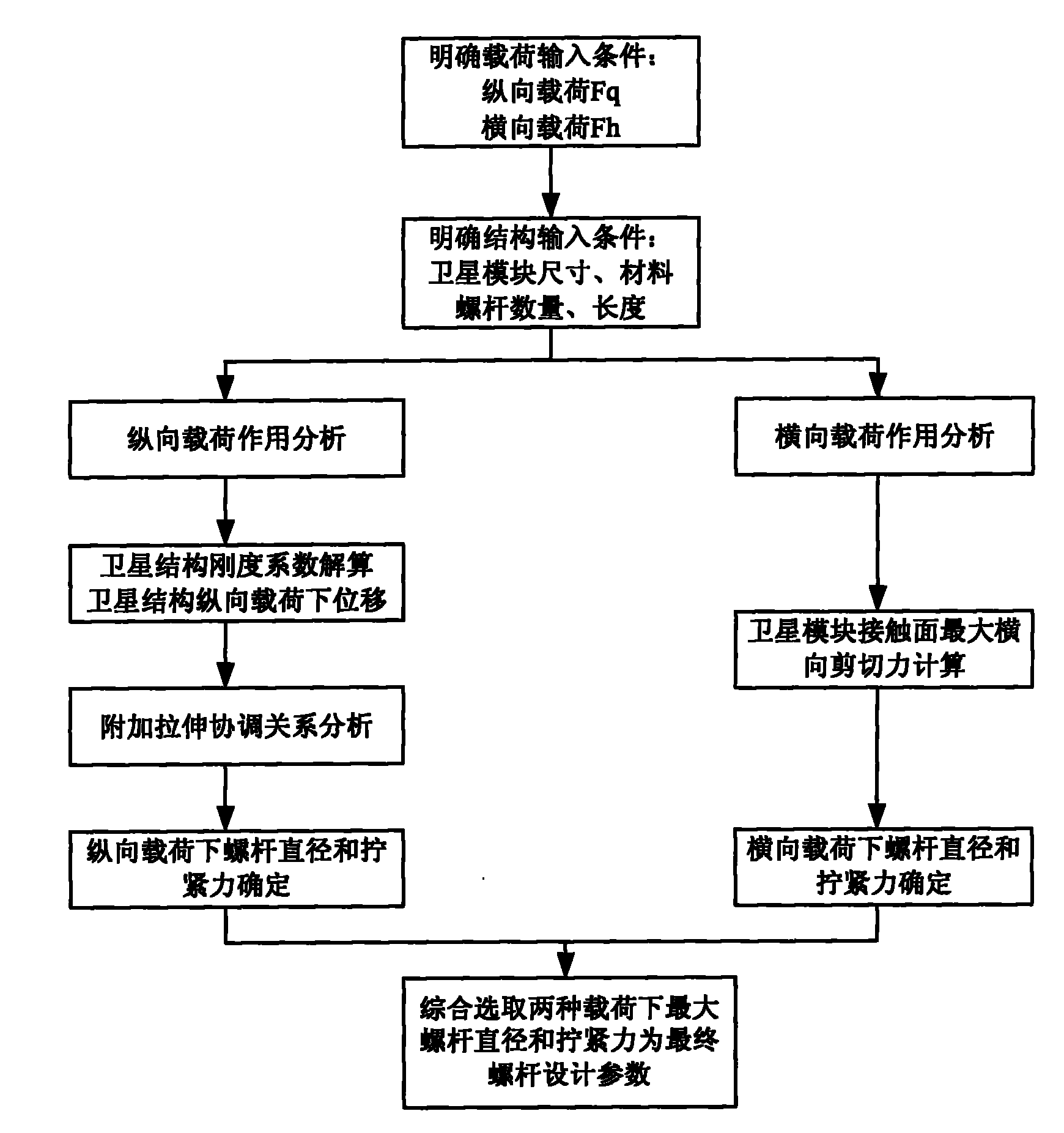

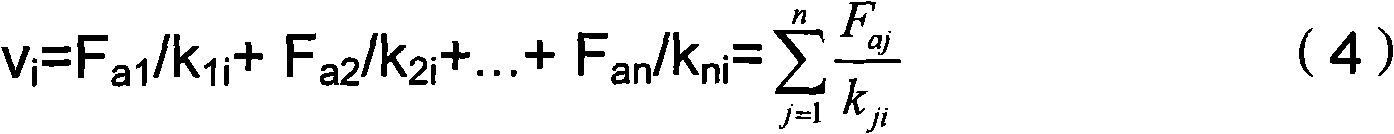

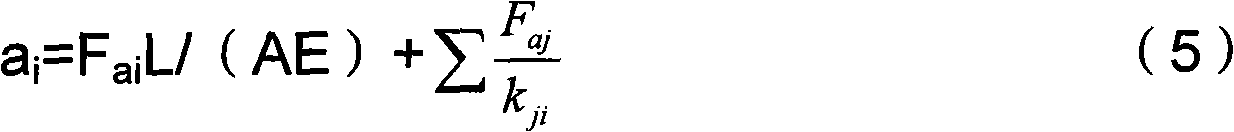

[0023] Under the external load force of the modular satellite, the tightening force exerted by each screw should ensure that the modules of the satellite do not separate. Secondly, the stress on the screw and the satellite structure should not exceed the material strength. Under this principle, the modular satellite is separated. Superimposed force analysis. Such as figure 1 As shown, it is a flow chart of the method of the present invention, considering the longitudinal load and the transverse load respectively. Under the longitudinal load, according to the superposition principle of external force-deformation, the coordinated deformation of the satellite structure and the screw is analyzed, the stiffness matrix is calculated, and the relationship between the screw parameters and the longitudinal external load that the satellite module does not separate under the longitudinal external load can be obtained, so that the longitudinal external load of the screw can be determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com