Composite tubular pump device

A tubular pump and compound technology, applied in the field of compound tubular pump device, can solve the problems of high sealing, ventilation and heat dissipation requirements, unsatisfactory hydraulic performance, difficult maintenance, etc., and achieves good ventilation and heat dissipation conditions and compact structure. , Beneficial to the effect of operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

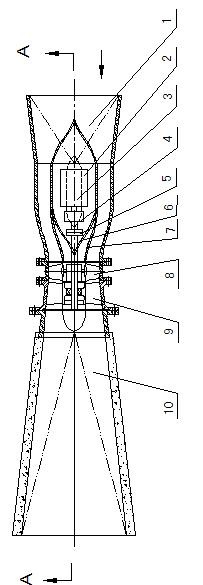

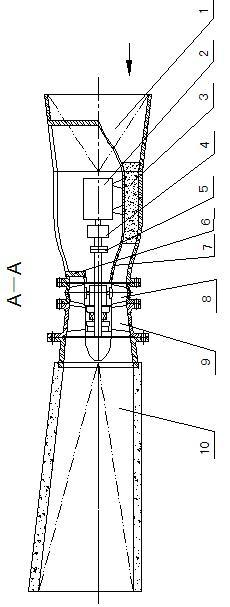

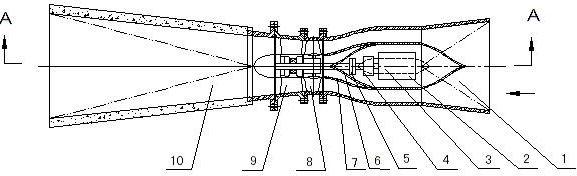

[0011] The specific implementation of the compound type tubular pump device of the present invention will be described below with reference to the accompanying drawings.

[0012] see figure 1 and figure 2 As shown, the composite tubular flow pump device of the present invention includes a water inlet channel 1, a half-shaft half-bulb type water inlet structure, a horizontal water pump unit and an outlet flow channel 10 connected in sequence, wherein the half-shaft half-bulb type The water inlet structure includes a hollow metal shell in the shape of a half-shaft and a half-bulb. The metal shell includes an upper shaft 6 and a lower bulb body 7. The cross-sectional shape of the upper shaft 6 is a streamlined shape with two pointed ends and a large middle one in the shape of a walnut. shape, the lower bulb body 7 is a half-bulb-shaped streamlined shape, and the maximum width of the upper shaft 6 is the same as the maximum diameter of the lower bulb body 7 to meet the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com