Fair-faced concrete and application thereof

A technology of fair-faced concrete and cement, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of small air bubbles, good fluidity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

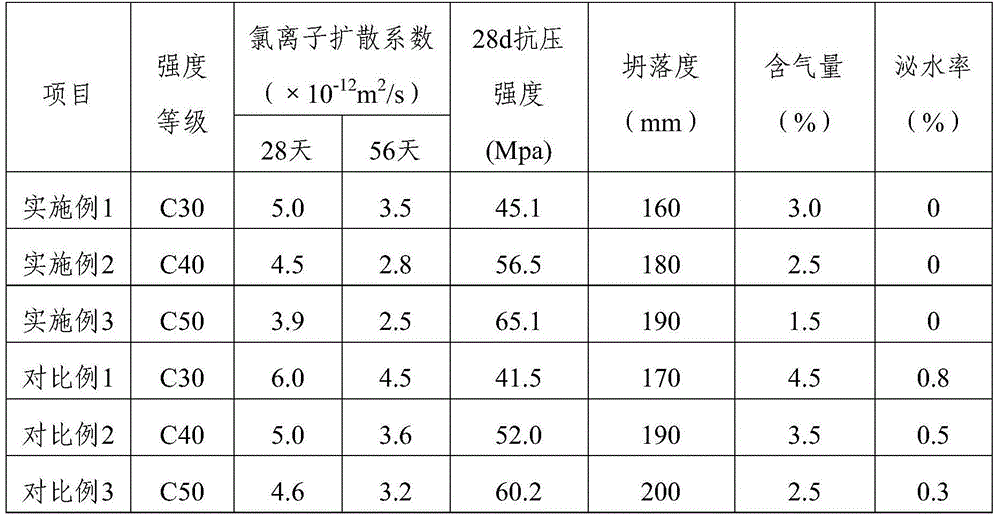

Examples

Embodiment 1

[0048] Each cubic meter of fair-faced concrete consists of the following components:

[0049] 220kg of cement, 130kg of granulated blast furnace slag powder, 50kg of fly ash, 2.358kg of composite water reducing agent, 820kg of crushed stone with a particle size within the range of 10-20mm, 205kg of crushed stone with a particle size within the range of 5-10mm, river sand 773kg, water 165kg;

[0050] The composite water reducer consists of 2.13kg of polyester polycarboxylate water reducer, 0.018kg of silicone ether copolymer defoamer, 0.09kg of alkylphenol ethylene oxide condensate air-entraining agent and polyvinyl alcohol It is formed by mixing 0.12kg of tackifier.

[0051] The strength grade of the obtained fair-faced concrete is C30 grade.

Embodiment 2

[0053] Each cubic meter of fair-faced concrete consists of the following components:

[0054] 189kg of cement, 126kg of granulated blast furnace slag powder, 105kg of fly ash, 3.57kg of composite water reducer, 798kg of crushed stone with a particle size within the range of 10-20mm, 266kg of crushed stone with a particle size within the range of 5-10mm, river sand 770kg, water 143kg;

[0055] The composite water reducer consists of 3.2kg of polyester polycarboxylate water reducer, 0.028kg of silicon ether copolymer defoamer, 0.14kg of alkylphenol ethylene oxide condensate air-entraining agent and polyvinyl alcohol It is made by mixing 0.2kg of tackifier.

[0056] The strength grade of the obtained fair-faced concrete is C40 grade.

Embodiment 3

[0058] Each cubic meter of fair-faced concrete consists of the following components:

[0059] 290kg of cement, 88kg of granulated blast furnace slag powder, 62kg of fly ash, 4.59kg of composite water reducing agent, 801kg of crushed stone with a particle size within the range of 10-20mm, 267kg of crushed stone with a particle size within the range of 5-10mm, and 742kg of river sand , water 150kg;

[0060] The composite water reducer consists of 4.13kg of polyester polycarboxylate water reducer, 0.035kg of silicon ether copolymer defoamer, 0.175kg of alkylphenol ethylene oxide condensate air-entraining agent and polyvinyl alcohol It is formed by mixing 0.25kg of tackifier.

[0061] The strength grade of the obtained fair-faced concrete is C50 grade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com