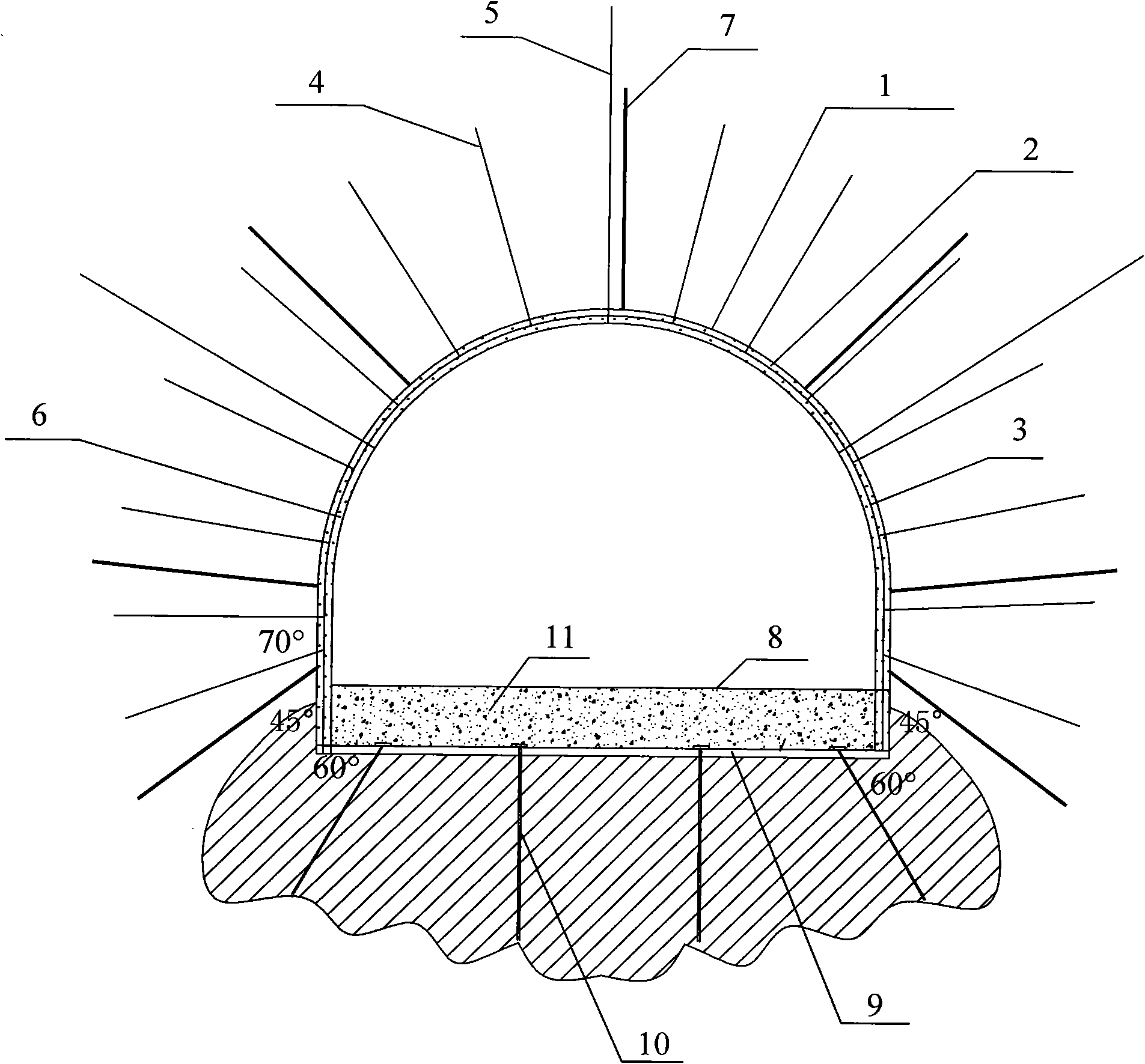

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

A technology of deep tunnels, rigid-flexible coupling, applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of complex construction, difficult maintenance, deformation of deep tunnels, etc., to improve the overall bearing capacity, solve particularly serious deformation, and avoid repairs. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The rigid-flexible coupling support of the deep well roadway anchor net cable and the overall reinforcement and support method of the surrounding rock in this embodiment are carried out according to the following steps:

[0023] a. Excavate the roadway according to the shape of the roadway section 1, and spray concrete on the surface of the surrounding rock formed by the excavation to form the initial sprayed concrete layer 2 to seal the surrounding rock and level the layer. The thickness of the initial sprayed concrete layer 2 is 50mm, and the strength is C20; immediately use reinforcement mesh 3 and bolt 4 to support the roadway surrounding rock, the diameter of reinforcement mesh is 6.5mm, the length×width of reinforcement mesh is 1700mm×1000mm, and the grid size is 100mm×100mm; the anchor rod adopts construction V Grade steel, the outer thread of the anchor rod is a left-handed thread without longitudinal reinforcement, and the yield strength of the anchor rod δ b ≥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com