Manufacture method of all-optical fiber heavy pressure gas chamber based on hollow photon crystal optical fibre

A technology for hollow-core photonic crystals and manufacturing methods, which can be applied to clad optical fibers, optical waveguides, and light guides, and can solve problems such as the difficulty in determining the size and distribution of air pressure, the inability to judge internal air pressure, and the difficulty in quantitatively studying nonlinear interactions between gas and media. , to reduce the uncertain factors of air pressure and ensure the effect of certainty

Inactive Publication Date: 2008-10-15

ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

View PDF1 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the core of the hollow-core photonic crystal fiber is only a few microns, the gas filling process belongs to the problem of micro-pipe flow, which makes it difficult to determine the gas pressure in the cavity and its distribution, especially when the length of the hollow-core photonic crystal fiber used is When it is too long, it is impossible to judge its internal pressure, which makes it difficult to quantitatively study the nonlinear interaction between gaseous media and light waves

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

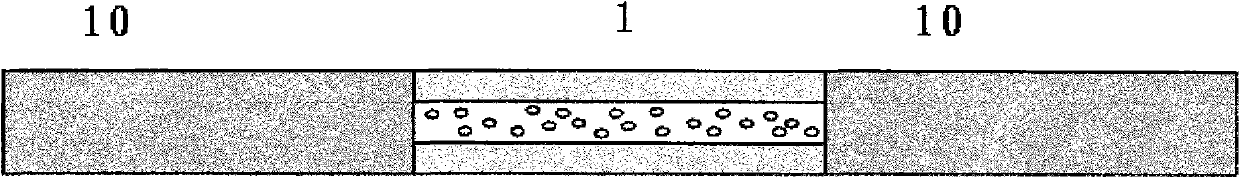

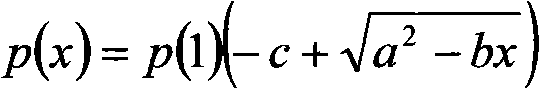

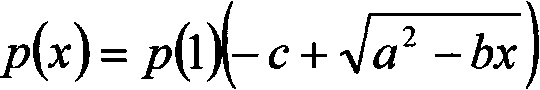

The invention discloses a manufacturing method for a full optical fiber high-pressure gas chamber based on a hollow-core photon crystal fiber. The steps of the invention are as follows: a) two ends of a hollow-core photon crystal fiber (1) are respectively communicated with an airtight A chamber (2) and an airtight B chamber (3), and one end of gas distribution equipment (4) is communicated with the airtight B chamber (3), and the other end of the gas distribution equipment (4) is respectively connected with a vacuum pump (5) and a gas source (6) to be inflated; b) the airtight B chamber (3) is connected with the vacuum pump (5) through the gas distribution equipment (4) first, after the required vacuum degree is achieved, the airtight B chamber (3) is connected with the gas source (6) to be inflated again through the gas distribution equipment (4) until air pressure of the airtight A chamber (2) is more than or equal to one atmospheric pressure; c)the two ends of the hollow-core photon crystal fiber (1) are successively welded with a standard single film fiber (10) within a range of less than or equal to 1.5 min; d) a distillation function p(x) of air pressure of a fiber core in the hollow-core photon crystal fiber (1) is derived from a formula p(x)=p(1)(-c+a2-bx); e) a final air pressure value of the full optical fiber high-pressure gas chamber is calculated by more than one p(x). The p(x) can accurately determine the air pressure value of the full optical fiber high-pressure gas chamber.

Description

technical field The invention relates to a method for manufacturing an all-fiber gas chamber, in particular to a method for manufacturing an all-fiber high-pressure gas chamber based on a hollow-core photonic crystal fiber. Background technique Hollow-core photonic crystal fiber (HC-PCF for short) is a new generation of low-loss transmission fiber developed in recent years. It has important applications in power light wave energy transmission, optical pulse dispersion and nonlinear transmission control, and new photonic devices. Since the hollow-core photonic crystal fiber confines the light wave in the large hole of the fiber core to transmit in the form of the fundamental mode, when the medium is filled in the large hole, the interaction area between the light wave and the filled medium can be kept at the micron level, while The low-loss transmission characteristics of the optical fiber ensure the effective interaction distance, which can significantly enhance the intera...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/02

Inventor 毛庆和孙青

Owner ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com