Fabricated type building automatic grouting equipment and method

A building automation and assembly technology, applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems affecting the fluidity of grouting materials, low degree of automation, overturning of pipes and grouting funnels, etc., to improve convenience and automation , reduce personnel demand, and control the effect of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

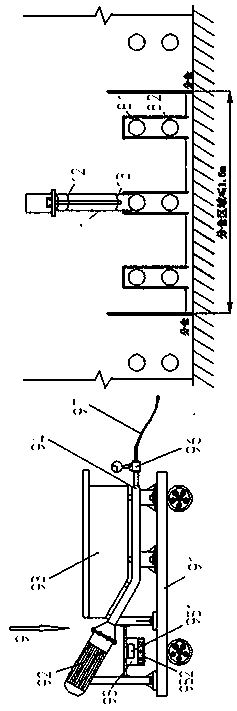

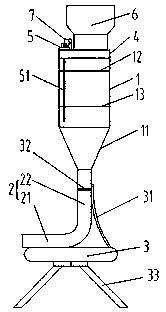

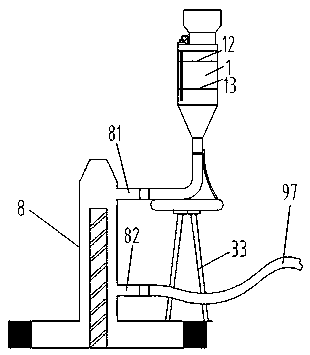

[0031] see Figure 1-3 , the prefabricated building automation grouting equipment of a specific embodiment, including a grouting machine 9 connected to the grouting port of the grouting sleeve for grouting and a grouting device connected to the grouting outlet of the grouting sleeve; Described grouting machine 9 comprises base frame 91, and described base frame 91 is provided with grouting pump 92, and the inlet end of described grouting pump 92 is connected with silo 93, and the outlet end is connected with grouting pipe 94 so as to communicate with the grouting sleeve. The grouting port; the grouting device includes a vertical grouting main cylinder 1, and the lower end of the grouting main cylinder 1 is provided with a communication pipe 2 so as to communicate with the grouting outlet of the grouting sleeve; the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com