Method for preventing and controlling bottom heaving disaster of mine stoping tunnel

A technology for mining roadways and disasters, which is applied to mining equipment, earthwork drilling, bolt installation, etc., and can solve the problem of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

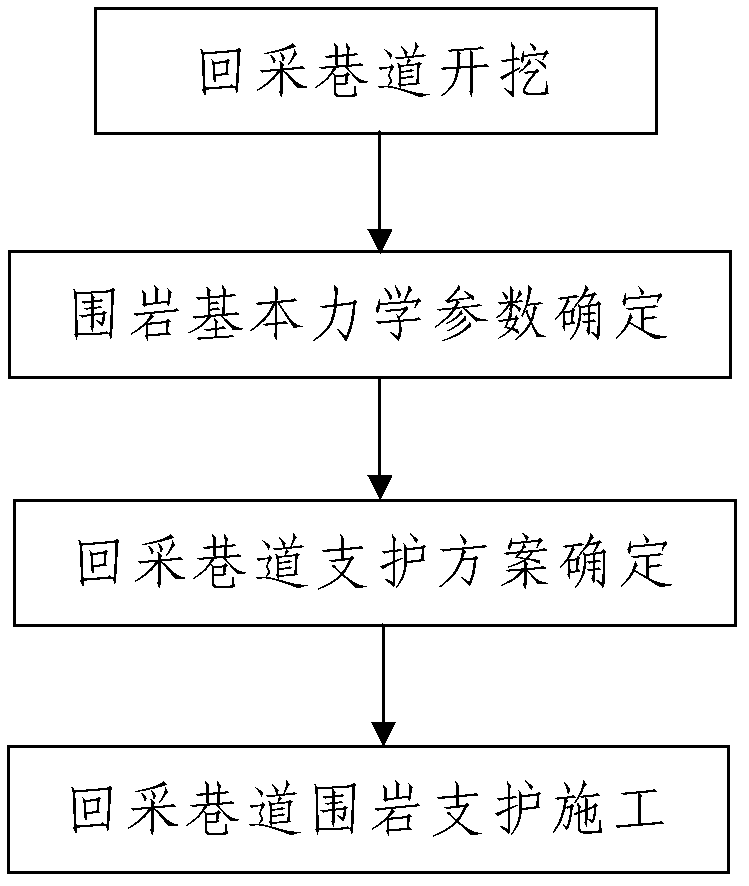

[0044] Such as image 3 Shown is a method for preventing and controlling disasters in mining roadway underfloor, comprising the following steps:

[0045] Step 1. Excavation of mining roadway: According to the construction method of conventional mine mining roadway excavation, the mining roadway to be prevented is excavated.

[0046] In this embodiment, the recovery roadway that needs to be prevented and controlled is the excavation and transportation channel of the 13503 working face of Wangcun Mine. The structures in the east and west are relatively simple, and the strata are relatively gentle; the secondary fold structure in the middle of the working face is relatively developed, and the dip angle of the strata in some sections is steep and the undulation is relatively large. The direction of the transportation trough is basically the same as that of the stratum. The stratum is inclined to NW direction, and the elevation gradually decreases from south to north. The average ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com