Optical film adhesive used for full bonding, preparation method and application of adhesive and optical film based on adhesive

An optical film and adhesive technology, applied in the field of optical films, can solve the problems of difficulty in exerting cohesiveness and adhesion, problems of product durability, and high cost of bonded materials, so as to solve the problems of cohesion and adhesion. Easy to peel off, prevent whitening and fogging, prevent high temperature and high humidity and boiled whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

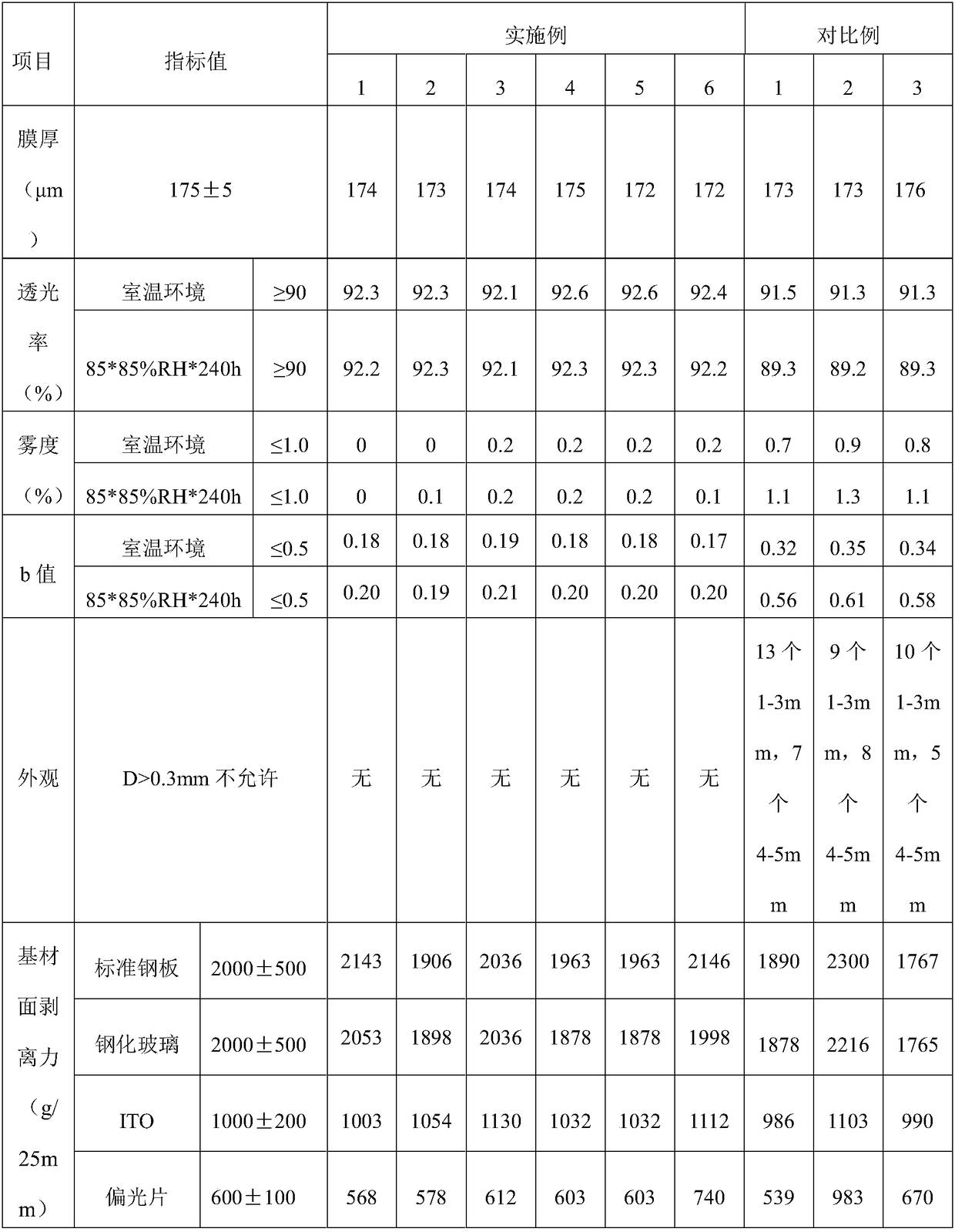

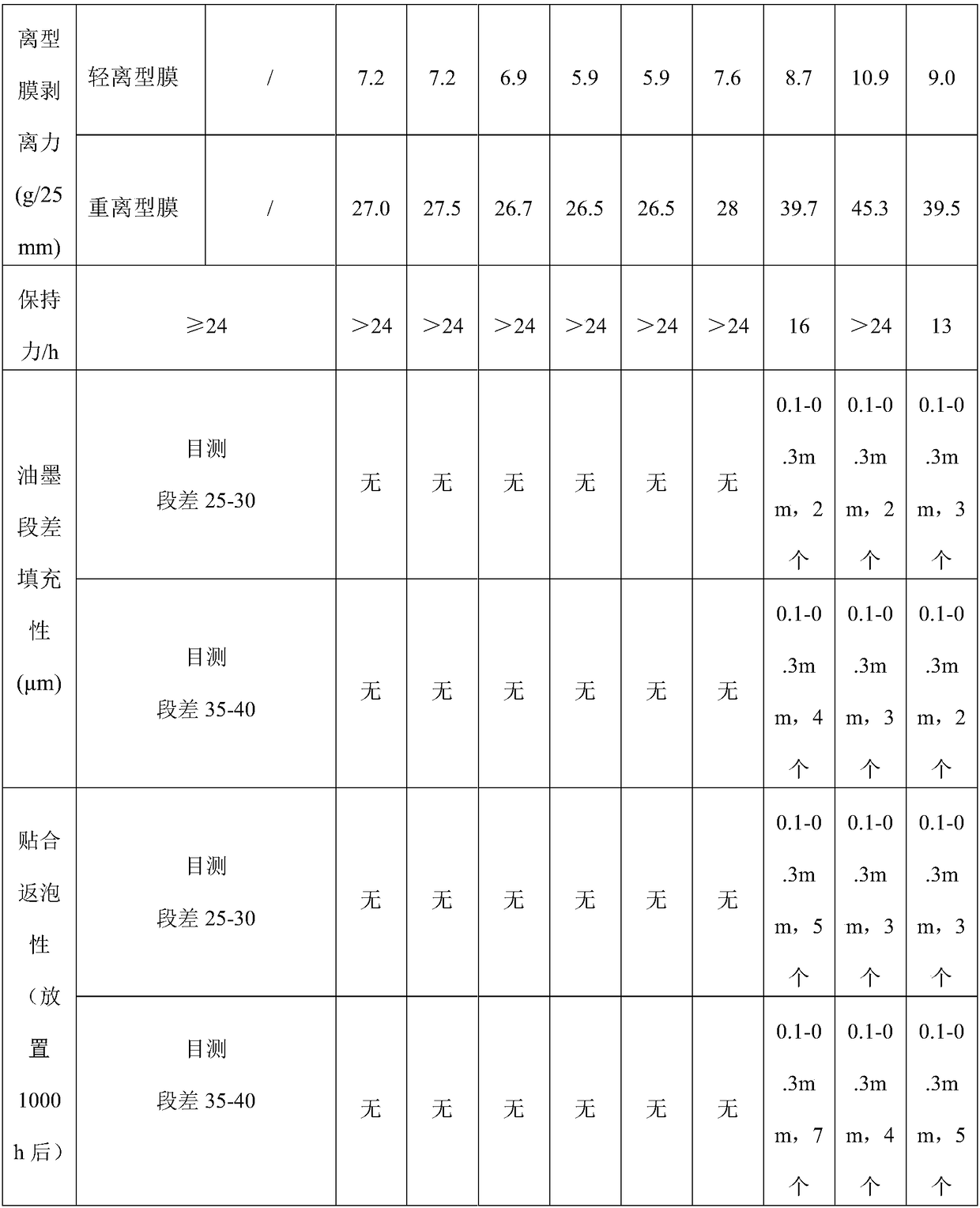

Examples

preparation example Construction

[0046] The preparation method of the acrylate copolymer of the present invention is a conventional free radical polymerization method, by adjusting the ratio of soft and hard monomers, adding different hydrophilic monomers to synthesize a series of resins with different Tg and hydroxyl values. The following is one of the preparation methods, but it is not the only preparation method. Other methods that can obtain the target structure of the copolymer of the present invention are all achievable methods of the present invention.

[0047] Typical preparation method of acrylate copolymer: monomer composition (total weight 100g): methyl methacrylate 10-30%, butyl acrylate 40-60%, hydroxyethyl acrylate 10-30%, acrylamide 2-10% %. It is mixed with 0.2-1.5% thermal initiator benzoyl peroxide, and reacted at 80° C. for 2 hours in a solvent-free environment to obtain an acrylate copolymer.

Embodiment 1

[0048] Embodiment 1: be used for the preparation of the adhesive of electronic equipment

[0049] 50g acrylate copolymer (Tg: -31°C, hydroxyl value: 25mgKOH / g, acid value: 0.1mgKOH / g), 0.03g adhesion modifier (ShinEtsu-X-41-1059A), 5g acrylate monomer (PETA) mixed with 43g organic solvent (33g methyl isobutyl ketone and 10g ethyl acetate); add 1g crosslinking agent (Bayer N3390) and stir to disperse evenly; add 0.1g photoinitiator (1-hydroxycyclohexylbenzene base ketone), uniformly dispersed, and filtered to obtain an adhesive used for electronic equipment.

Embodiment 2

[0050] Embodiment 2: be used for the preparation of the adhesive of electronic equipment

[0051] 50g acrylate copolymer (Tg: -15℃, hydroxyl value: 40mgKOH / g, acid value: 0.5mgKOH / g), 0.05g adhesion modifier (ShinEtsu-X-41-1059A), 3g acrylate monomer (PETA) mixed with 43g organic solvent (33g methyl isobutyl ketone and 10g ethyl acetate); add 1g crosslinking agent (Bayer N3390) and stir to disperse evenly; add 0.1g photoinitiator (1-hydroxycyclohexylbenzene base ketone), uniformly dispersed, and filtered to obtain an adhesive used for electronic equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com