Optical adhesive tape and preparation method thereof, optical glue

An optical glue and optical technology, applied in the field of optical glue, can solve the problems of low thickness, easy breakage, and difficult rework, etc., and achieve the effect of good step filling ability and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

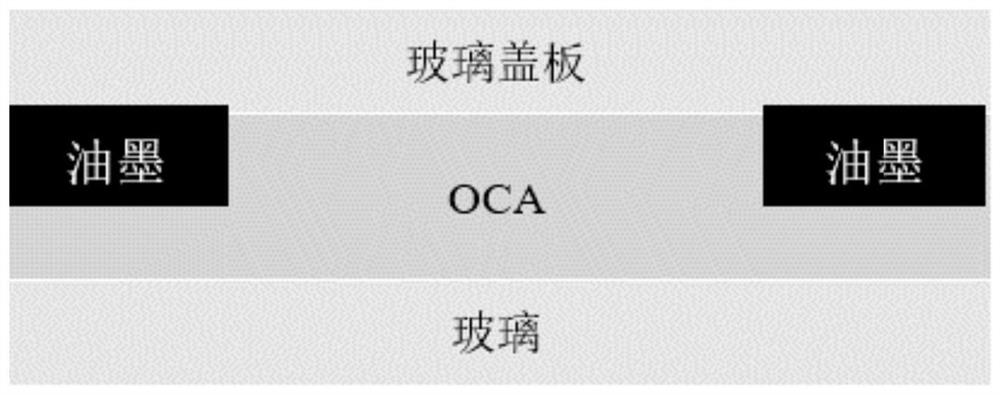

Image

Examples

preparation example Construction

[0069] The embodiment of the present invention also provides a preparation method of optical adhesive tape, comprising:

[0070] In parts by mass, mix 20-80 parts of soft monomer, 10-50 parts of hard monomer, 2-30 parts of functional monomer and 0.1-2 parts of thermal initiator to obtain a mixed solution, raise the temperature, and mix the The liquid is dropped into the reaction solvent, fully reacted, and acrylic resin is obtained;

[0071] In terms of parts by mass, add 0.0001 to 0.5 parts of metal complexes, 0.5 to 10 parts of photopolymerizable monomers and 0 to 0.4 parts of photoinitiators to 40 to 50 parts of acrylic resin, stir evenly and coat the film, then Dry to obtain optical tape.

[0072] In this embodiment, the soft monomers, hard monomers and functional monomers are polymerized in a solution, and the polymerization temperature (ie temperature rise) may be 80°C.

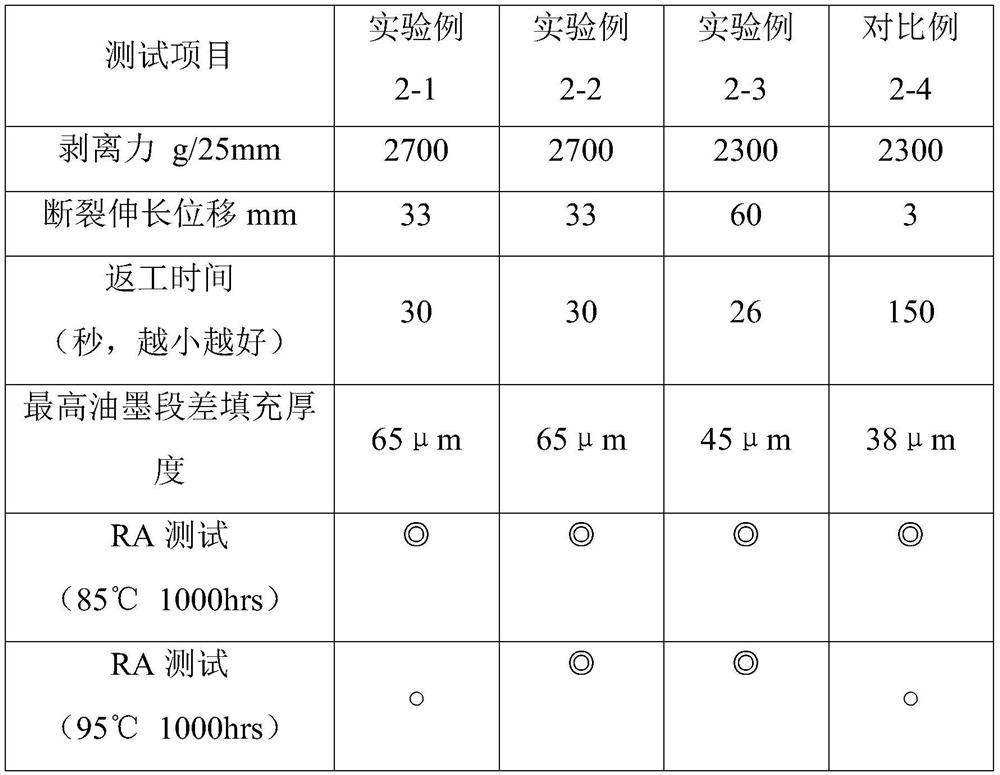

[0073] The experimental examples of the present invention will be further described below through ...

experiment example 1

[0075] Weigh 46g of butyl acrylate, 10g of methyl methacrylate, 10g of hydroxyethyl methacrylate, and 5g of acrylamide, mix them with 1% AIBN, and set aside. Weigh 100g of ethyl acetate and 50g of toluene, put them into the bottom of the reaction kettle, stir evenly, and fill with nitrogen to remove oxygen for one hour. Raise the temperature of the system to 80°C, drop the mixture of monomer and initiator into the reactor within three hours, and keep it warm for two hours. That is to obtain resin A (that is, the above-mentioned acrylic resin, the same below), and the viscosity of resin A is 3000-5000.

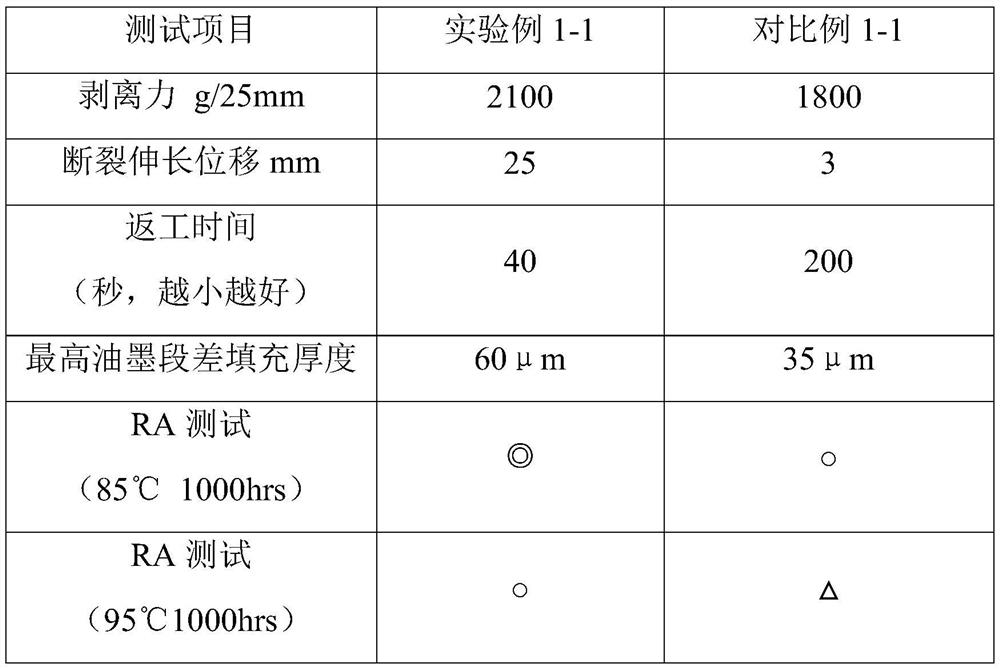

experiment example 1-1

[0077] The aluminum acetylacetonate was diluted with toluene into a 1% aluminum acetylacetonate-toluene solution by mass fraction. Take 50g of resin A, add 0.4g of 1% aluminum acetylacetonate-toluene solution by mass fraction, stir evenly, scrape the film on PET (polyethylene terephthalate) with a hand scraper, and dry the solvent in an oven. The thickness of the prepared tape was 100 μm. Test the tape's peel force, elongation at break, rework performance, etc.

[0078] The peel force and elongation at break of the adhesive tape can be measured by referring to the test method of GB / T2792-2014 adhesive tape peel strength. For example, when performing a peel force test, cut a 25mm*10cm tape and paste it on the glass, and use a tensile machine to test the peel force at room temperature at a speed of 100mm / min. Rework performance refers to: attach the display part of the mobile phone with optical tape first, then disassemble it, remove the optical tape on the display part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com