Machining technology for car power battery copper bar

A technology of automotive power battery and processing technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of vehicle safety threat, copper bus failure, short circuit, etc., to achieve batch operation, small packaging space , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

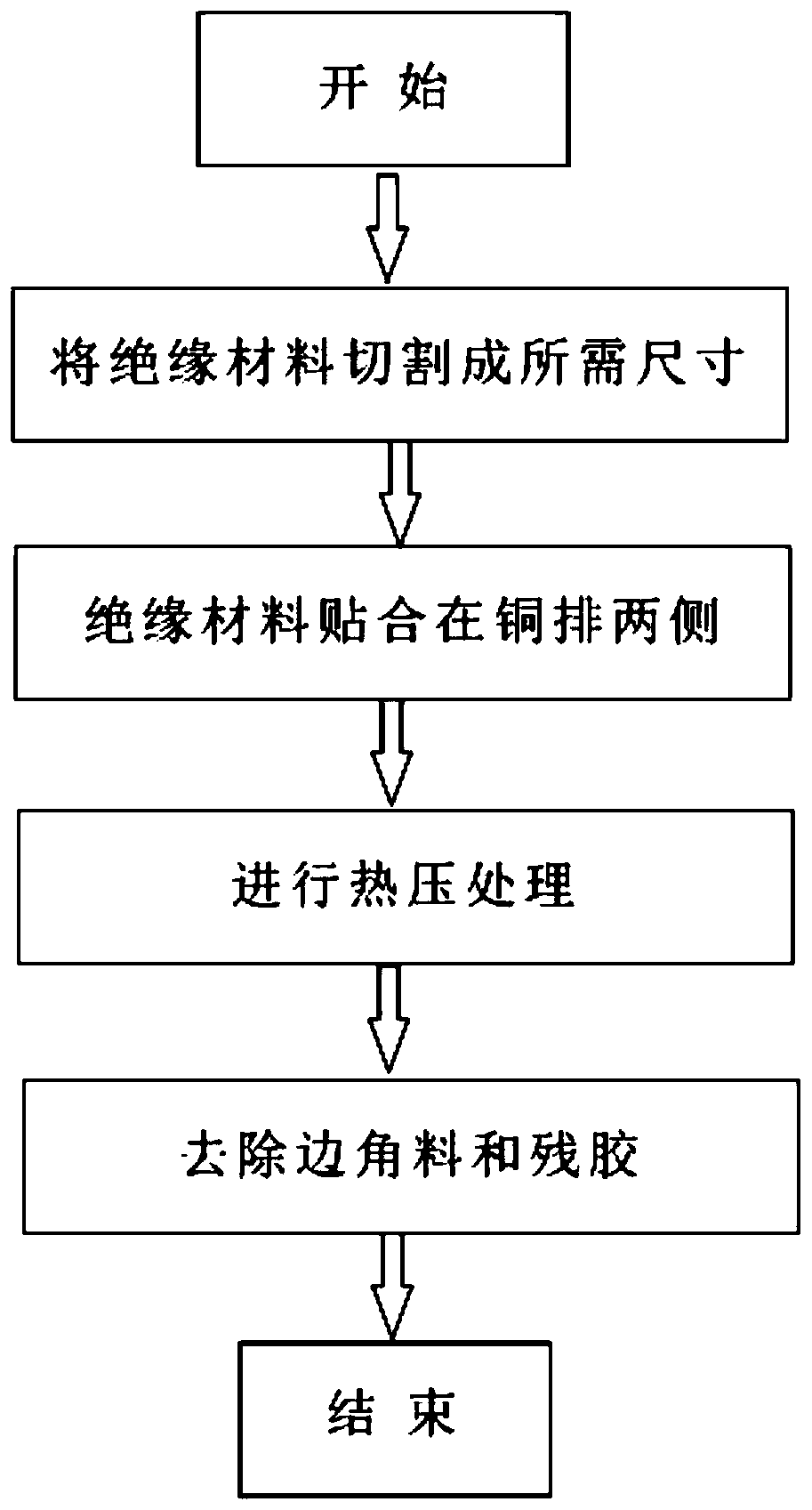

[0017] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0018] see figure 1 , the present invention provides a kind of processing technology of automobile power battery copper bar, comprises the following steps:

[0019] S1: Process the insulating material to the required size;

[0020] S2: The processed insulating material is distributed on both sides of the copper bar, and stacked according to the structure of insulating material-copper bar-insulating material to obtain a pre-stack;

[0021] S3: placing the pre-stacked object on a heat press machine for heat press treatment;

[0022] S4: Remove excess scrap and residual glue.

[0023] First in step S1, the insulating material is a PI insulating material, and the PI insulating material has a three-layer structure, including a PI film, an adhesive layer and a release paper, and the adhesive layer is located between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com