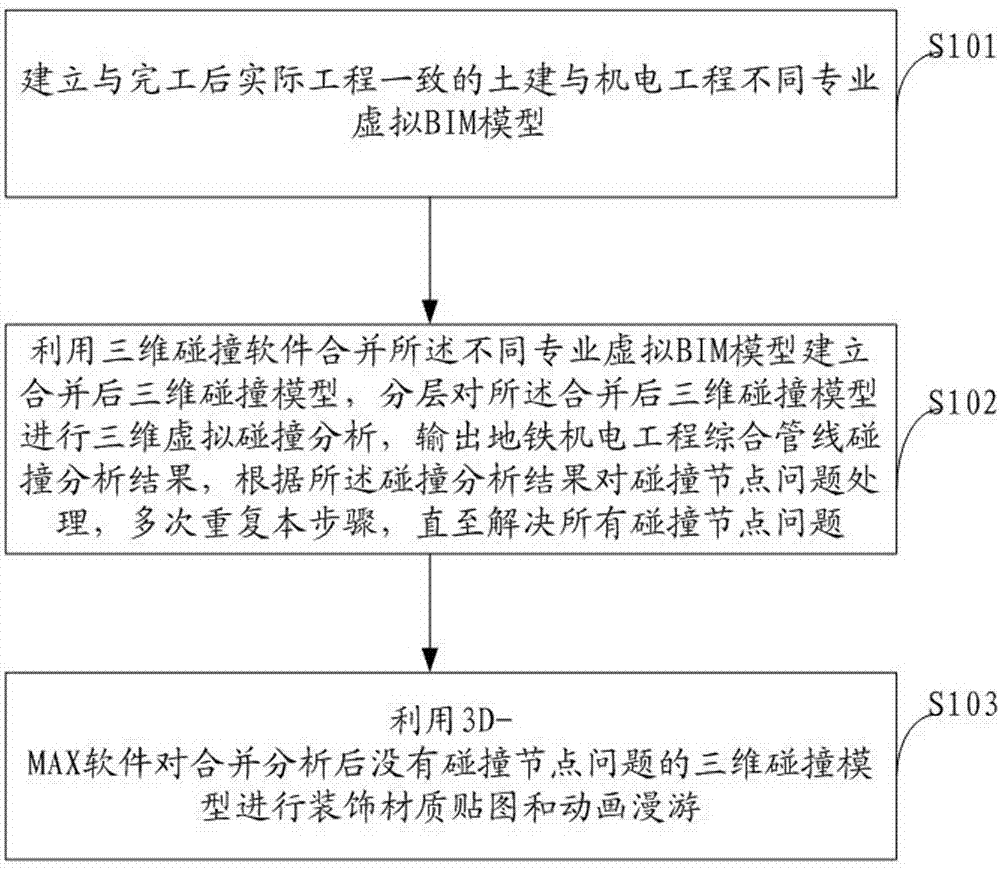

Complex pipeline collision optimization method of subway electromechanical engineering

A technology of integrated pipelines and optimization methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as increased construction costs and low construction efficiency, and achieve the goal of reducing construction waste, saving construction time, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

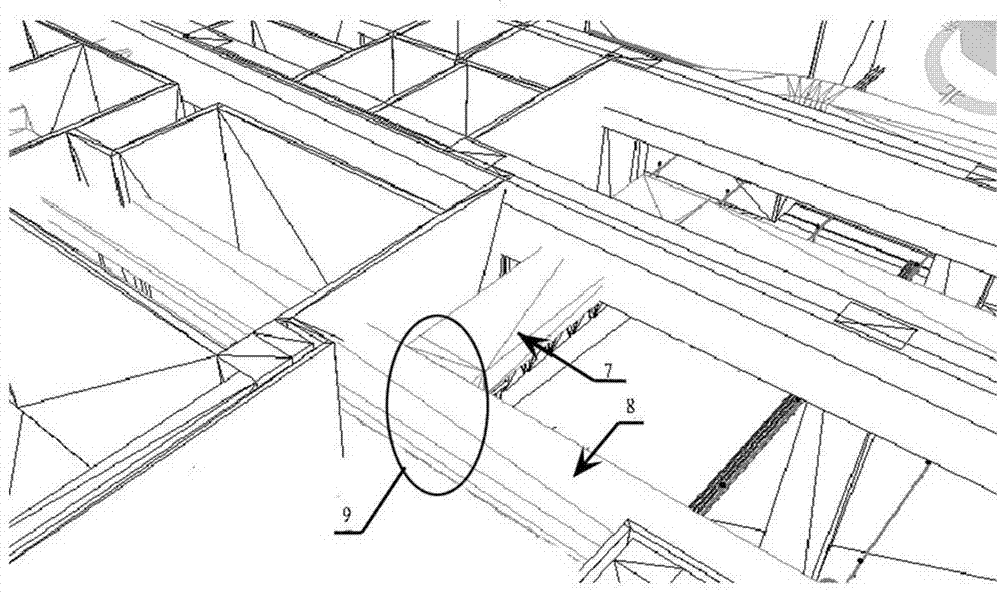

[0066] Example 1: Collision of fire pipes and exhaust pipes;

[0067] see picture , it can be seen from the BIM model that there is a collision between the fire pipe 1 and the exhaust pipe 2, and the position 3 shown in the circle is the collision node between the fire pipe 1 and the exhaust pipe 2, and the collision position is recorded on the plan drawing And solutions, in this way, only need to lower the elevation of the fire water pipe before the fire water pipe meets the exhaust pipe to avoid conflicts, and can be avoided during the construction process.

Embodiment 2

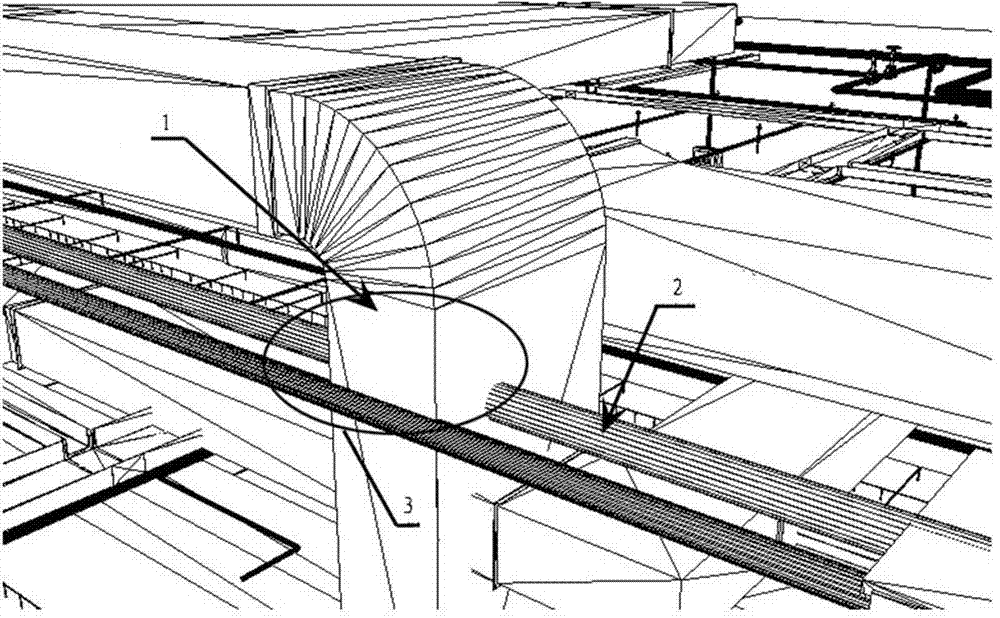

[0068] Example 2: Collision between exhaust pipe and cable tray.

[0069] see Figure 4 shown, from Figure 4 It can be seen that there is a collision between the exhaust pipe 4 and the cable tray 5, and the collision occurs at the position 6 (collision node) indicated by the circle in the figure. Through construction experience, it can be considered that the elevation of the air duct here can be lowered by 200mm to avoid collision. And record the location of the collision point on the plane construction drawing, and notify the air duct processing team that during the air duct processing, the air duct elbow at the blue-green junction should be properly adjusted to meet the elevation of the air duct and avoid collision with the bridge frame. In this way, we save the waste of labor and materials that may be caused by rework.

[0070] Through the BIM collision detection analysis, the construction plan was optimized, the friction between various disciplines was reduced, the phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com