Heavy metal pollution plot remediation device

A technology for heavy metals and plots, applied in the field of soil remediation, can solve the problems of high cost of soil remediation, serious soil pollution, complex treatment process, etc., and achieve the effects of simple structure, low energy consumption, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

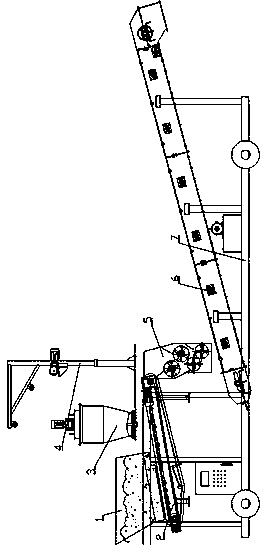

[0039] Embodiment 1, heavy metal polluted plot remediation device, such as figure 1 As shown, the mobile flat car 7 is included, and the mobile flat car 7 can be moved to improve the flexibility during use.

[0040] The front portion of the mobile flat car 7 is provided with an upper hopper 1, the top of the upper hopper 1 is provided with a feed port, the bottom of the upper hopper 1 is provided with a discharge port, and the discharge port is provided with a dial wheel. Prior art, not shown in the figure.

[0041] The provided loading hopper 1 is suitable for the hook machine feeding operation, and the material shifting wheel arranged at the discharge port can control the height of the discharge layer.

[0042] When in use, the soil is added to the upper hopper 1 through the hook machine, so as to facilitate the repair of the soil and have high flexibility in use.

[0043] A feeder 2 is arranged below the discharge port of the upper hopper 1, wherein the feeder 2 is a belt...

Embodiment 2

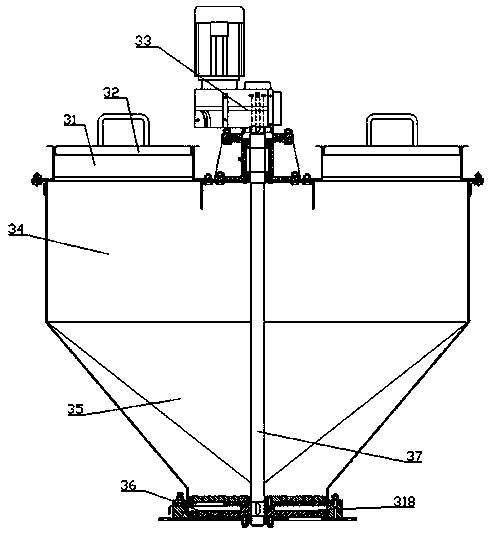

[0091] Embodiment 2, the difference between this embodiment and embodiment 1 is: as Figure 13 As shown, the medicament filling machine includes a liquid medicament filling machine 8, and the liquid medicament filling machine 8 is provided with a stirring shaft and stirring blades arranged on the stirring shaft. A discharge pipe 9 is arranged on the liquid medicament filling machine 8, a metering pump is set on the discharge pipe 9, the end of the discharge pipe 9 is located on the feeder 2, and an atomizing nozzle is arranged at the end of the discharge pipe 8, through which the atomizing nozzle can The liquid agent is atomized to increase the contact area between the agent and the soil and improve the restoration effect. During implementation, since the liquid medicament can be lifted to the feeder through the quantitative pump, the liquid medicament filling machine 8 is directly arranged on the mobile flat car 7, the position is relatively low, and the dosing is convenient....

Embodiment 3

[0092] Embodiment 3, the difference between this embodiment and Embodiment 1 is: as Figure 14 As shown, the medicament filling machine includes a liquid medicament filling machine and a powder medicament filling machine, and the liquid medicament filling machine 8 is provided with a stirring shaft and stirring blades arranged on the stirring shaft. A discharge pipe 9 is arranged on the liquid medicament filling machine 8, a metering pump is set on the discharge pipe 9, the end of the discharge pipe 9 is located on the feeder 2, and an atomizing nozzle is arranged at the end of the discharge pipe 8, through which the atomizing nozzle can The liquid agent is atomized to increase the contact area between the agent and the soil and improve the restoration effect. During implementation, since the liquid medicament can be lifted to the feeder through the lifting pump, the liquid medicament filling machine 8 is directly arranged on the mobile flat car 7, and the position is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com