Preparation of bimetallic sulfide with conductive carbon cloth as substrate and application thereof in negative pole of lithium-ion battery

A technology of conductive carbon cloth and sulfide, applied in battery electrodes, nickel compounds, electrode manufacturing, etc., can solve the problems of limited research on LIBs anode materials, and achieve the effects of simple assembly, high reproducibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

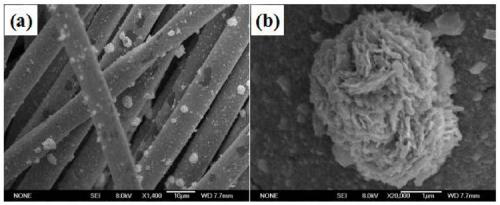

[0032] 1. Pretreatment of conductive carbon cloth

[0033] 1.1 Cut the conductive carbon cloth into a rectangle of 2×4cm. Use acetone, hydrochloric acid, and absolute ethanol to ultrasonically clean for 10 minutes, and dry them for later use.

[0034] The concentration of hydrochloric acid in step 1.1 is 1mol L -1 .

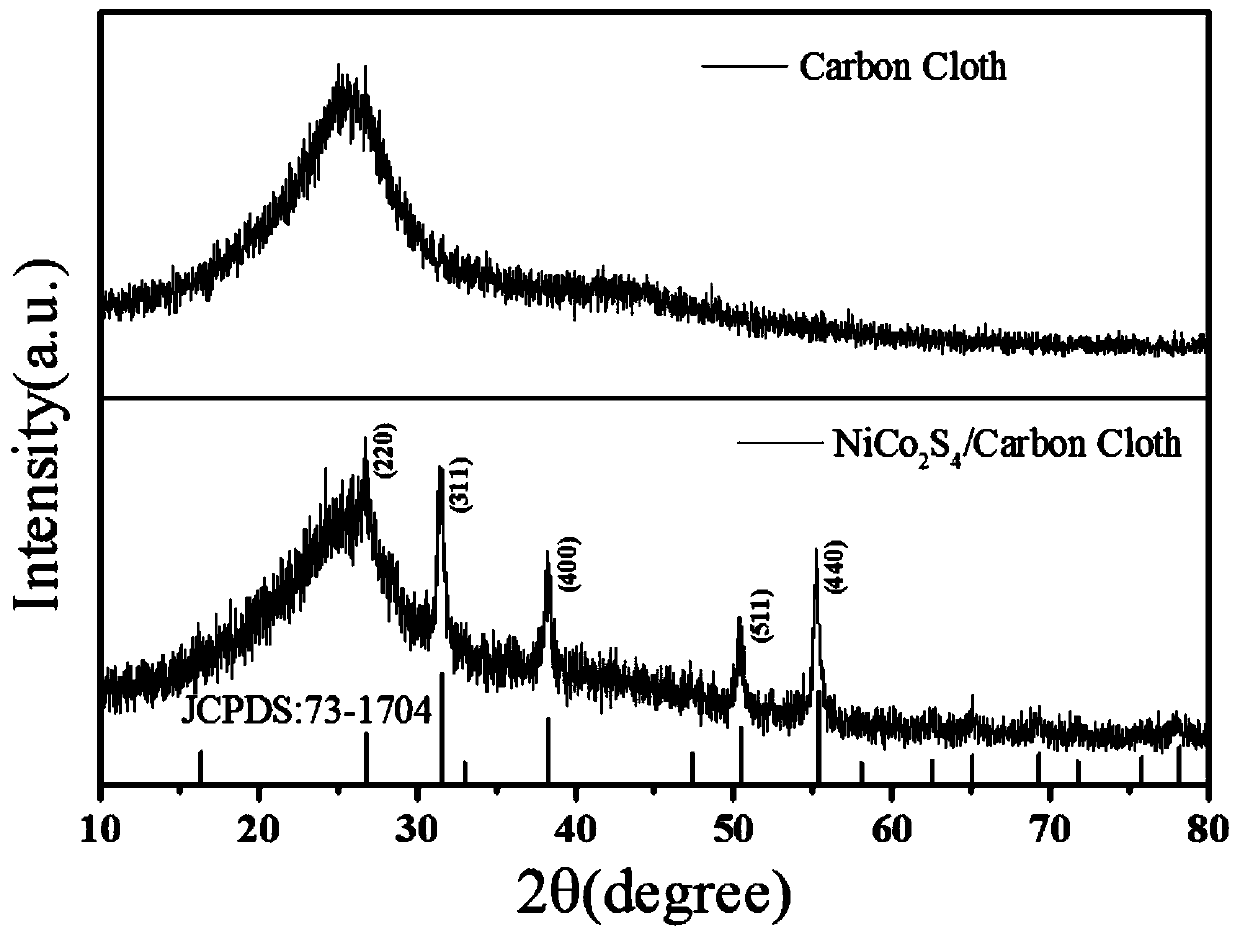

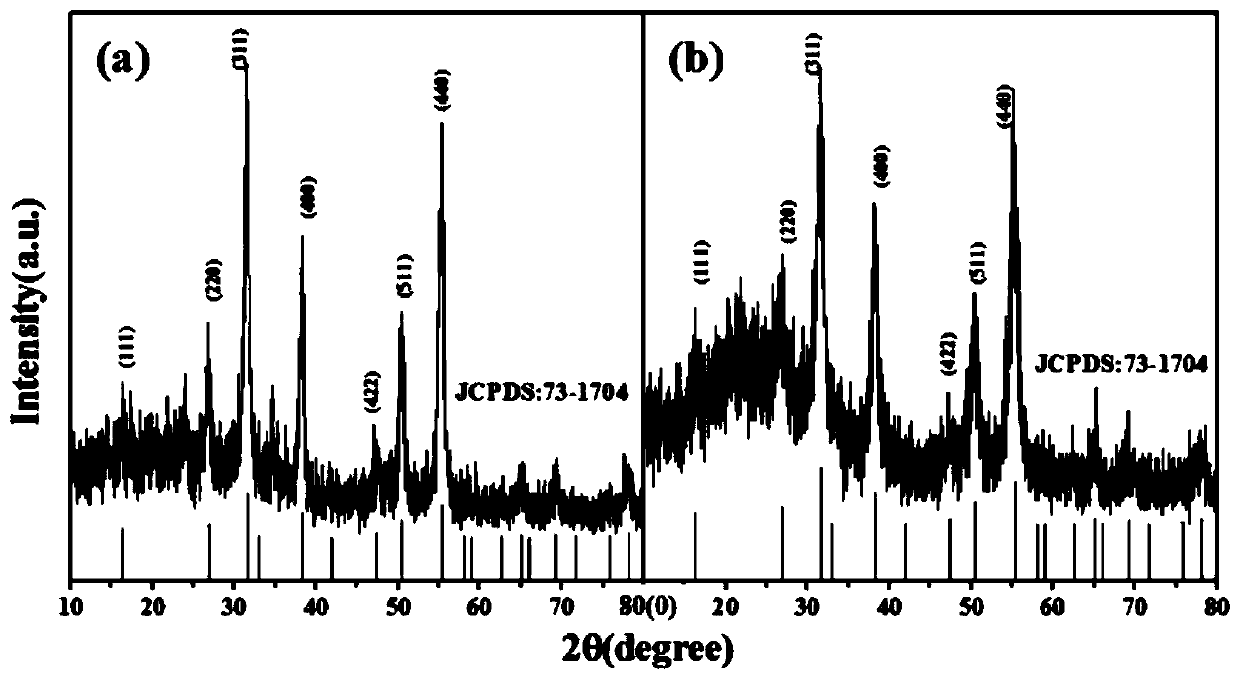

[0035] 2. NiCo on conductive carbon cloth 2 S 4 preparation of

[0036] 2.1 Dissolve an appropriate amount of ammonia water and o-phenanthroline in deionized water, stir evenly, add a certain proportion of cobalt nitrate hexahydrate and nickel nitrate hexahydrate, and stir evenly.

[0037] 2.2 Add an appropriate amount of thiourea to the above solution, and stir magnetically for 30 minutes.

[0038] 2.3 Transfer the solution described in 2.2 into a high-pressure reactor, and put it into the conductive carbon cloth treated in step 1.1, heat it for a certain period of time, cool it down to room temperature naturally, separate the precipitate by centrifugation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com