A kind of maintenance method of concrete member

A technology for concrete and components, applied in the field of construction, can solve the problems of inability to effectively prevent the phenomenon of efflorescence of concrete capillary pores, easy pollution of the environment, poor film-forming performance, etc., and achieves excellent application value, simple maintenance method, and good film-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0029] Synthetic Example 1 Synthesis of Bromine-Containing Compounds

[0030] Add 80g of potassium bromide and 0.4g of sodium silanolate to 100g of diethylene glycol, stir and react in an ice-water bath for 3 hours, raise the temperature to room temperature, and stir for 2 hours to react; wash the reaction product twice with water, separate the organic layer, anhydrous magnesium sulfate Drying, filtering, and distilling out the product under reduced pressure are bromine-containing compounds; the reaction formula is as follows:

[0031]

Synthetic example 2

[0032] Preparation of Synthetic Example 2 Moisturizing and Antifungal Agent

[0033] The main reactions are as follows:

[0034]

[0035] First, mix 1Kg of bromine-containing compound, 10g of lanthanum trifluoromethanesulfonate and 200g of imidazole, place in a container, and react with microwave heating to obtain a crude product; add 1.8Kg of water and 120g of ethylenediamine-N to the above crude product, N′-diacetic acid and 360g of ammonia water with a concentration of 30% were soaked for 10 hours, filtered, and the filter residue was dried to obtain a solid powder; the microwave heating time was 150 seconds, and the power was 720w;

[0036] Then 1Kg of solid powder, 20Kg of 1,3-butanediol, and 120g of potassium carbonate were added to the reactor, refluxed for 0.5 hours, and cooled to room temperature to become the moisturizing antifungal agent;

Synthetic example 3

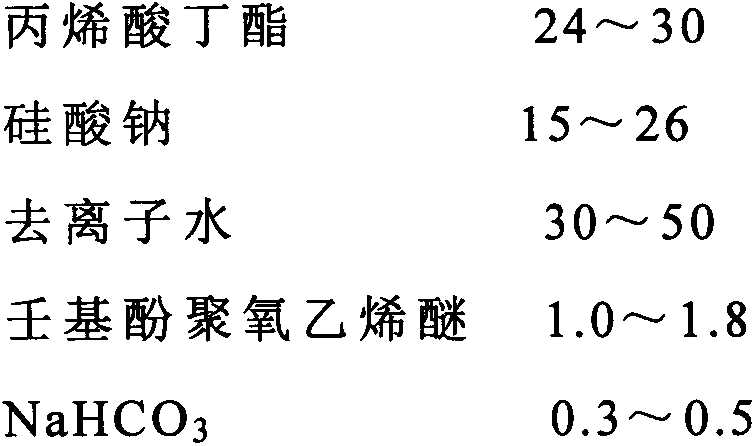

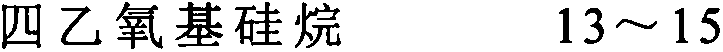

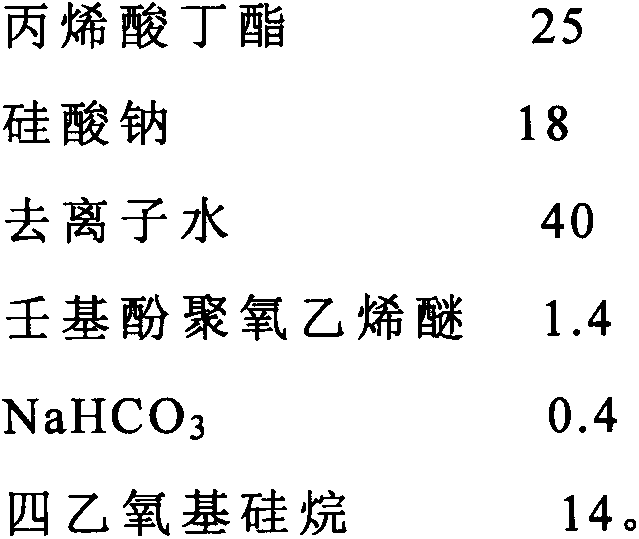

[0037] Preparation of Synthetic Example 3 Curing Agent

[0038] (1) Mix 100g butyl acrylate and 40g deionized water to obtain mixture A;

[0039] (2) In a nitrogen atmosphere, add 120g of deionized water, 6.4g of nonylphenol polyoxyethylene ether and 1.6g of NaHCO to the reactor in sequence 3 , stirring at 50°C for 30 minutes to obtain mixture B;

[0040] (3) Mixture A and mixture B were mixed and stirred for 55 minutes to obtain mixture C;

[0041] (4) Add 64g of tetraethoxysilane into the mixture C; then keep the temperature at 60°C for 0.5h; stop heating and cool to room temperature; then add 72g of sodium silicate to obtain the curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com