Floating circular current oil receiver and circular current separating method

An oil skimmer and ring pipe technology, which is applied in the field of floating circulation skimmer and circulation separation, can solve the problems of difficulty in operation, limited effect, and difficult to popularize, and achieve the effects of improving separation efficiency, adjusting kinetic energy freely, and ensuring the adjustment function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

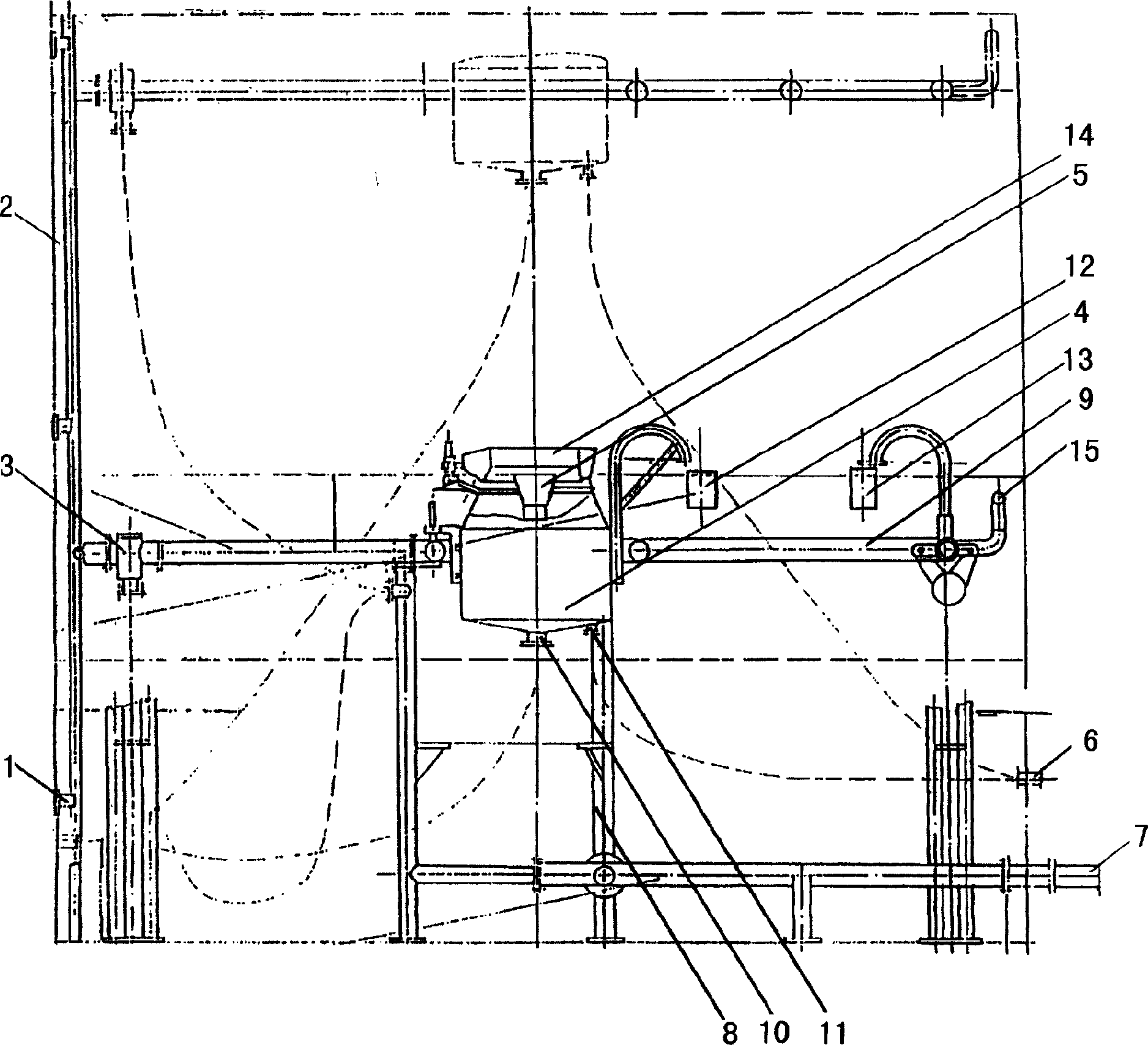

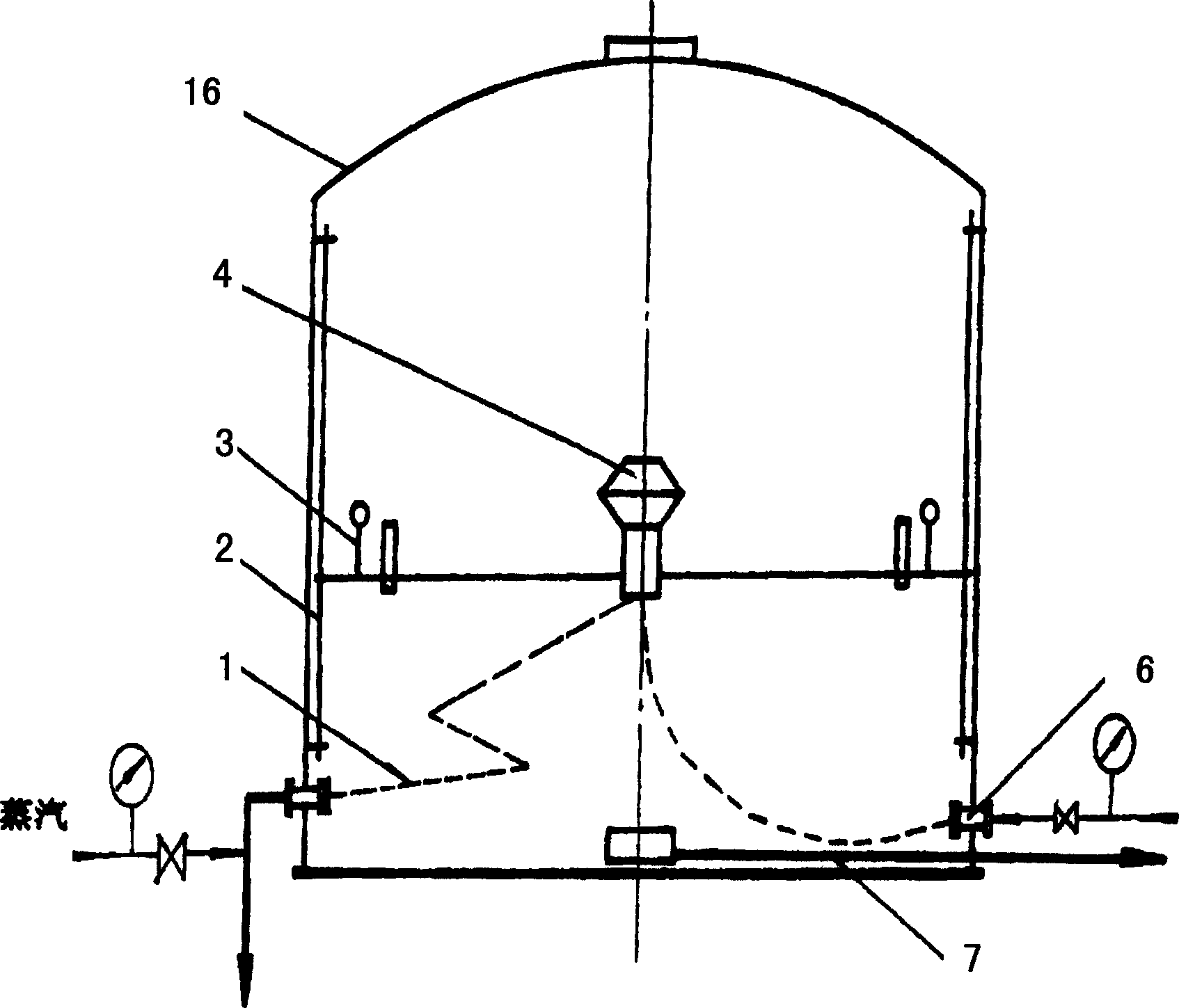

[0049] Such as figure 1 As shown, the oil collecting tank 4 of the present invention is connected with the ring pipe 9 by a chain, and the bottom of the oil collecting tank 4 and the ring pipe 9 is provided with a support rod 8; the oil collecting ring 14 on the top of the oil collecting tank 4 is provided with an oil collecting bucket 5; The bucket 5 is connected to the oil outlet pipe 1; the water outlet 11 of the oil collection tank at the bottom of the oil collection tank 4 is connected to the external pumping equipment through a hose; The outlet pipe 7 required by the separation time; the outer surface of the oil collection tank 4 is provided with an oil collection tank buoy 12; the ring pipe 9 is provided with a buoy 3, a ring pipe buoy 13 and a water jet pipe 15; the water inlet pipe system 6 is connected to the ring pipe 9; Ring pipe 9 cooperates with the pulley on the guide bar 2.

[0050] The oil outlet pipe 1 and the oil collecting ring 14 are provided with heat tr...

Embodiment 2

[0081] The present invention can also be arranged in the oily sewage pond, other is the same as embodiment 1.

Embodiment 3

[0083] The present invention can also be arranged in the wide water area that is rich in oily sewage, other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com