Insertion type vibration rolling construction method of asphalt concrete core of earth and rockfill dam

A kind of asphalt concrete and construction method technology, which is applied in the direction of dams, barrages, and foundation structure engineering, etc. It can solve the problems of many times of vibratory rolling, slow construction, and high asphalt consumption, so as to reduce the number of rolling construction times and shorten the construction time. , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Include the following steps:

[0023] a. Asphalt mixture and transition material paving:

[0024] Use the paver used in the construction of the roller compacted asphalt concrete core wall to pave the asphalt mixture and transition materials on both sides of the core wall at the same time, as follows:

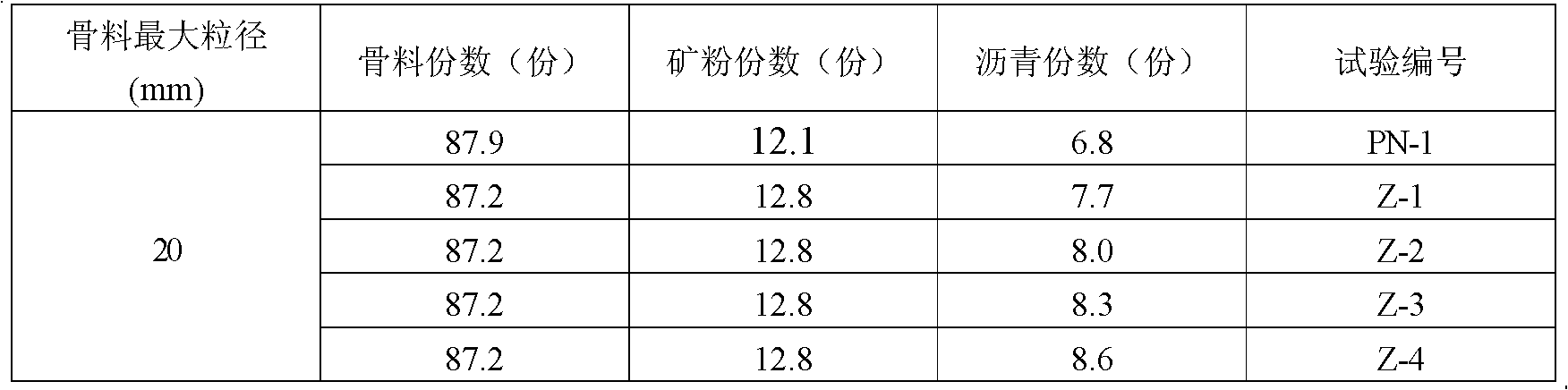

[0025] The total content of asphalt concrete aggregate and mineral powder is 100%. The performance of the aggregate and mineral powder should meet the requirements of the "Code for Design of Asphalt Concrete Face and Core Wall of Earth-rock Dam (SL501-2010)", of which aggregate: 83%, the maximum The particle size is 15mm, and the rest is mineral powder;

[0026] Asphalt: asphalt is used to meet heavy traffic road petroleum asphalt, asphalt content: 6.5%;

[0027] The temperature of the asphalt mixture entering the formwork silo is 160°C;

[0028] b. Vibration and compaction of asphalt mixture:

[0029] A knife-type vibrator is hung at the tail of the asphalt paver. Th...

Embodiment 2

[0036] Include the following steps:

[0037] a. Asphalt mixture and transition material paving:

[0038] Use the paver used in the construction of the roller compacted asphalt concrete core wall to pave the asphalt mixture and transition materials on both sides of the core wall at the same time, as follows:

[0039] The total content of asphalt concrete aggregate and mineral powder is 100%. The performance of the aggregate and mineral powder should meet the requirements of the "Code for Design of Asphalt Concrete Face and Core Wall of Earth-rock Dam (SL501-2010)", of which aggregate: 86%, the maximum The particle size is 25mm, and the rest is mineral powder;

[0040] Asphalt: Asphalt adopts hydraulic asphalt, asphalt content: 7.1%;

[0041] The temperature of the asphalt mixture entering the formwork silo is 162°C;

[0042] b. Vibration and compaction of asphalt mixture:

[0043] A knife-type vibrator is hung at the tail of the asphalt paver. The vibrator vibrates the asph...

Embodiment 3

[0050] Include the following steps:

[0051] a. Asphalt mixture and transition material paving:

[0052] Use the paver used in the construction of the roller compacted asphalt concrete core wall to pave the asphalt mixture and transition materials on both sides of the core wall at the same time, as follows:

[0053] The total content of asphalt concrete aggregate and mineral powder is 100%. The performance of the aggregate and mineral powder should meet the requirements of "Code for Design of Asphalt Concrete Face and Core Wall of Earth-rock Dam (SL501-2010)", of which aggregate: 90%, the maximum The particle size is 35mm, and the rest is mineral powder;

[0054] Asphalt: ordinary road petroleum asphalt is used as the asphalt, and the asphalt content: 7.7%;

[0055] The temperature of the asphalt mixture entering the formwork silo is 165°C;

[0056] b. Vibration and compaction of asphalt mixture:

[0057]A knife-type vibrator is hung at the tail of the asphalt paver. The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com