Good-texture healthy boiled noodle

A healthy, cooking technology, applied in the processing of dough, pre-baked dough, medical preparations containing active ingredients, etc., to achieve the effect of easy digestion and inhibition of viscosity rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

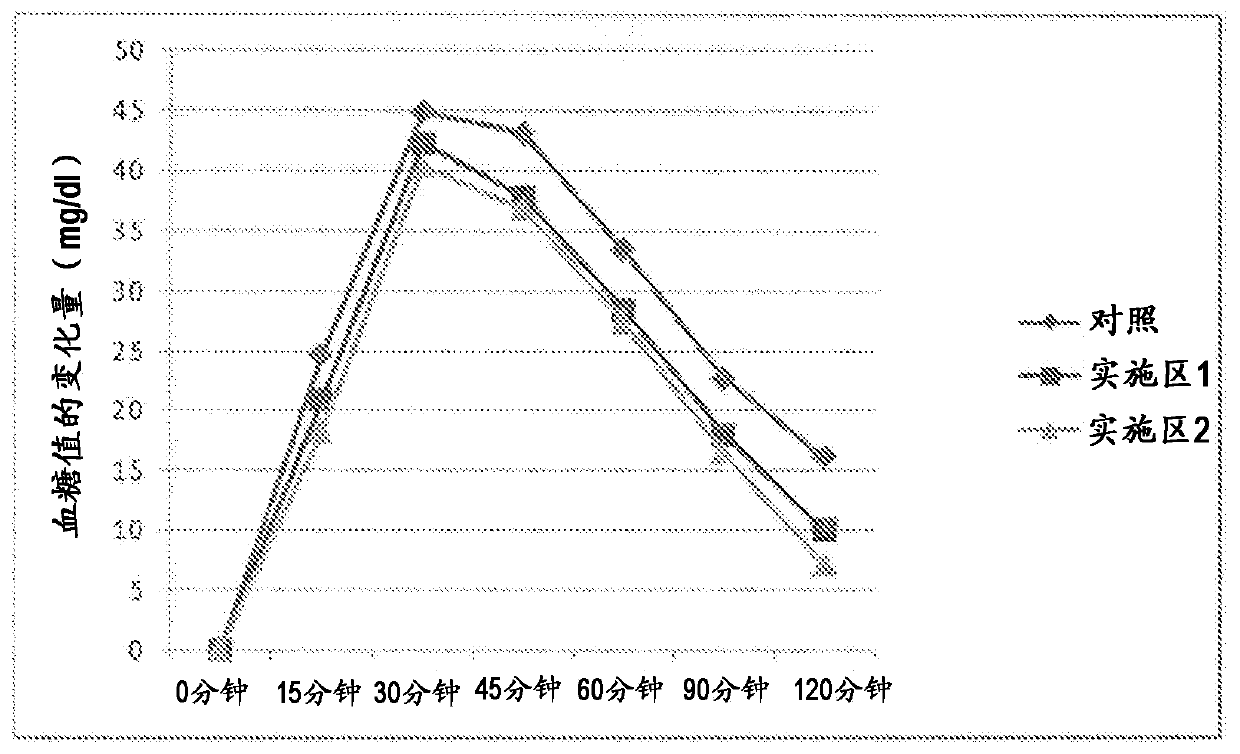

[0075] The effect of suppressing the increase in blood sugar level after eating was confirmed for udon noodles added with 5 parts by weight (with respect to the powder raw material) and 8 parts by weight (with respect to the powder raw material) of Ca alginate over 270 mesh.

[0076] 〔Preparation of udon noodle samples〕

[0077] After uniformly mixing the powder materials described in [Table 1], respectively add the kneading water described in [Table 1], knead for 10 to 16 minutes under the condition of a reduced pressure of 80 kPa, and obtain the temperature Loose kneaded dough at 28-34°C. The kneaded dough is made into a rough noodle belt with a thickness of 10mm by using a noodle forming roll, and compounded with the same thickness, and then rested at 25°C for 60 minutes under non-drying conditions, and rolled by a 3-stage flat roll Thickness 3.6mm, and finely cut into noodles using cutting teeth with a groove width of 3.5mm.

[0078] The obtained noodles were boiled in 9...

Embodiment 2

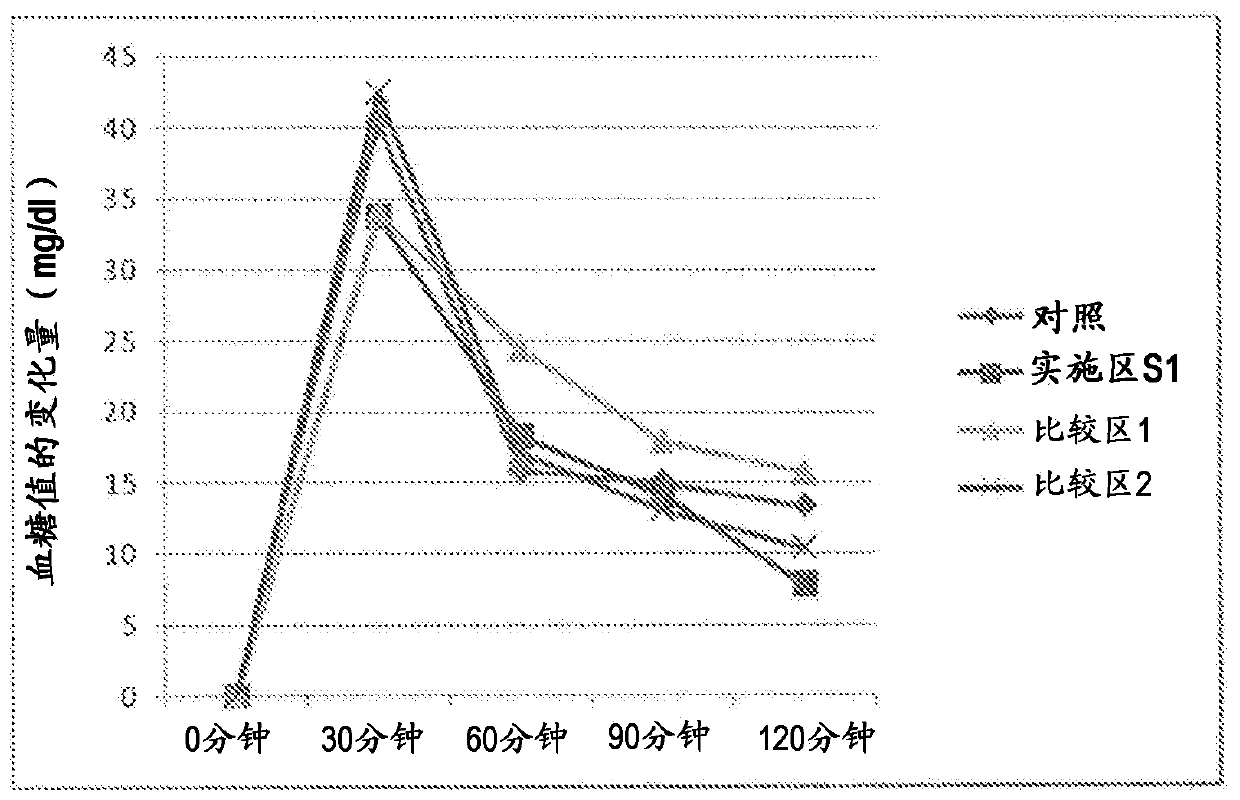

[0099] In Example 2, comparison was made with the case of simultaneously orally ingesting a suspension of alginic acid Ca. The case of eating the control boiled udon noodles of Example 1 was used as a control, and the case of eating the same in the implementation area 1 was referred to as the implementation area S1. It should be noted that calcium alginate equivalent to 2.8 g of over 270 mesh was kneaded into 180 g of the udon noodle sample of the embodiment area 1 . The comparison area 1 is set as the following situation: the 2.8 g of calcium alginate over 270 mesh is suspended in 100 ml of water and ingested, and then the boiled udon noodles of the comparison of Example 1 are eaten; the comparison area 2 is set as the following situation: After eating the boiled udon noodles of the control of Example 1, the 270-mesh calcium alginate suspension was similarly ingested.

[0100] 〔How to measure blood sugar level〕

[0101] The measurement of the blood sugar level was performed...

Embodiment 3

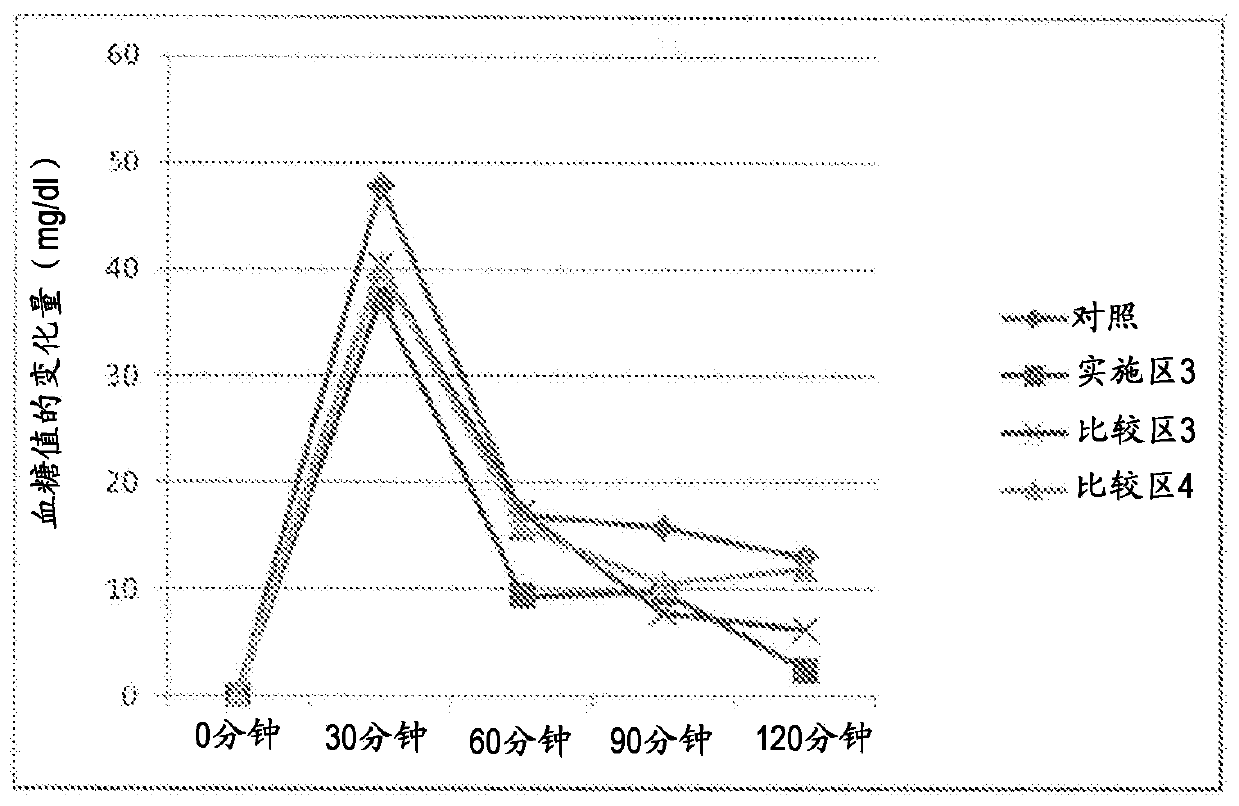

[0118] The effect of suppressing the increase in blood sugar level after eating was compared between boiled udon noodles to which sodium alginate was added instead of calcium alginate and boiled udon noodles to which alginate Ca gel-forming treatment was further performed.

[0119] [Sample preparation method]

[0120] In the control plot of Example 3 and the implementation plot 3, it prepared similarly to Example 1 except having set it as the wheat flour mainly containing "Kitahobo". For the comparative area 3 in which Na alginate was added and the comparative area 4 in which Ca alginate gel was formed, the powder raw materials described in [Table 10] were uniformly mixed and kneading water was added, and the process of Example 1 was carried out. In the noodle making process, the noodles were cooked for the cooking time described in [Table 10]. It should be noted that, for comparison zone 4, the etherified tapioca starch with a gelatinized viscosity higher than that of acetyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com