Plant and method for the production of metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

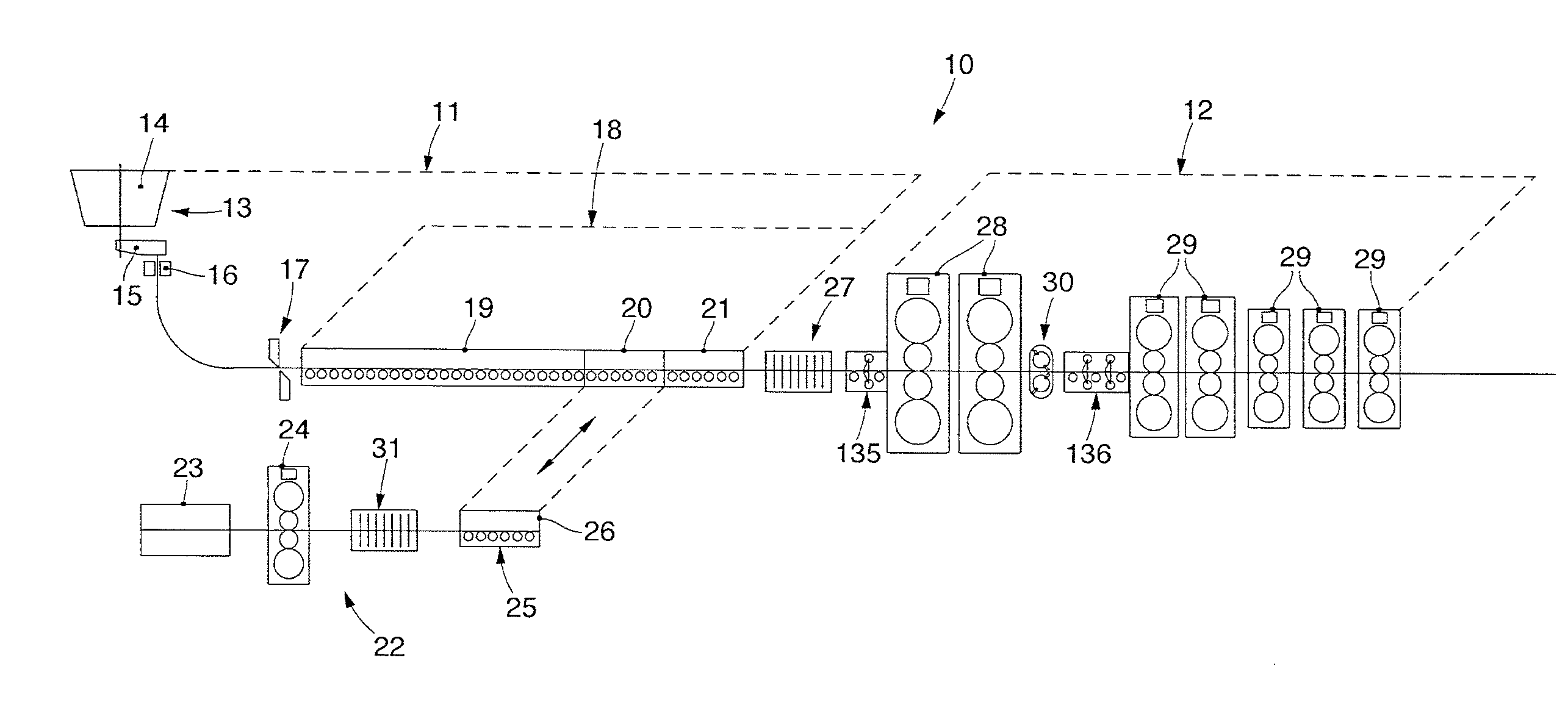

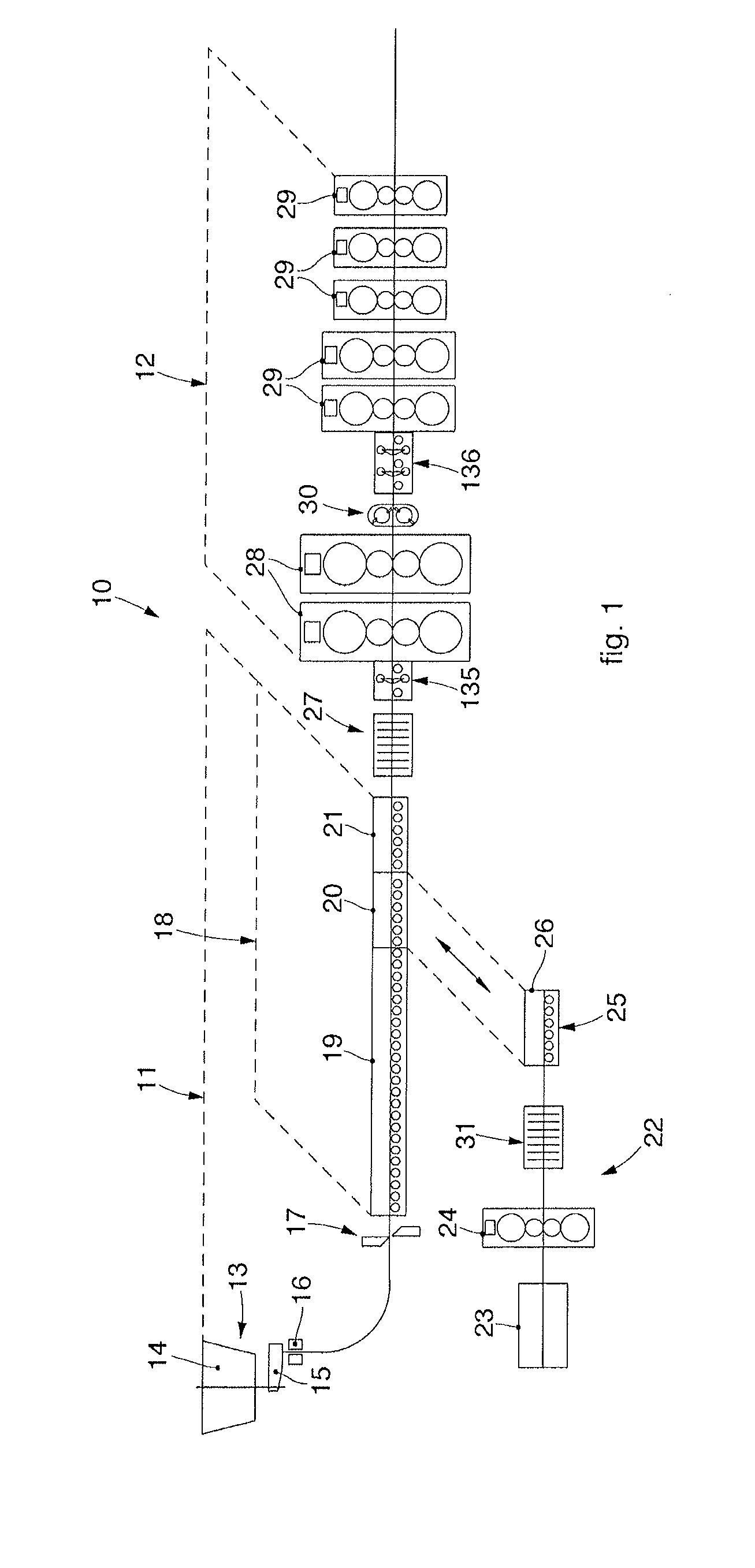

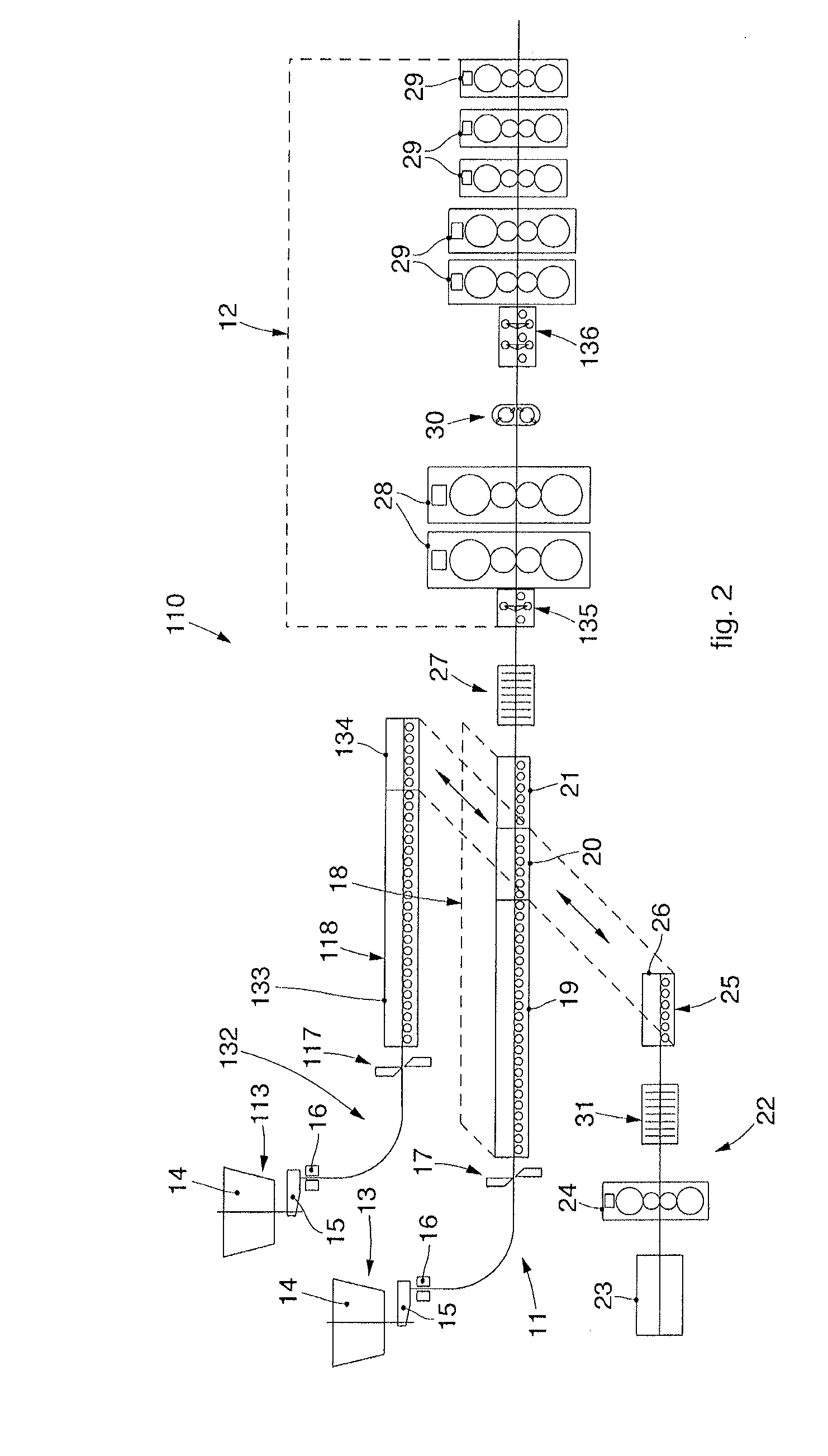

[0050]With reference to FIG. 1, a plant for the production of metal products is indicated in its entirety by the reference number 10 and comprises at least one main casting line 11 of thin slabs and one main rolling line 12 located downstream and aligned to the main casting line 11.

[0051]The main casting line 11 comprises a casting machine 13 configured to cast the liquid metal arriving for example from a melting plant, not shown in the drawings.

[0052]As shown in FIG. 1, the casting machine 13 can comprise a ladle 14, a tundish 15 and an ingot mold 16 in which the metal liquid is solidified to be sent for subsequent rolling.

[0053]In accordance with some forms of embodiment, the ingot mold 16 is the type suitable to cast thin slabs.

[0054]According to possible formulations of the present invention, a shearing device 17 is provided immediately downstream of the casting machine 13, such as pendulum shears, to shear the cast thin slabs to a pre-fixed length.

[0055]Downstream of the castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com