Low-concentrate type fermented total mixed ration for dairy cows and preparation method thereof

A technology for dairy cows and mixtures, applied in applications, animal feed, animal feed, etc., can solve problems such as difficult to effectively use, reduce feed dry matter intake, reduce palatability, etc., improve palatability and digestibility, and avoid animal picky eaters phenomenon, the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

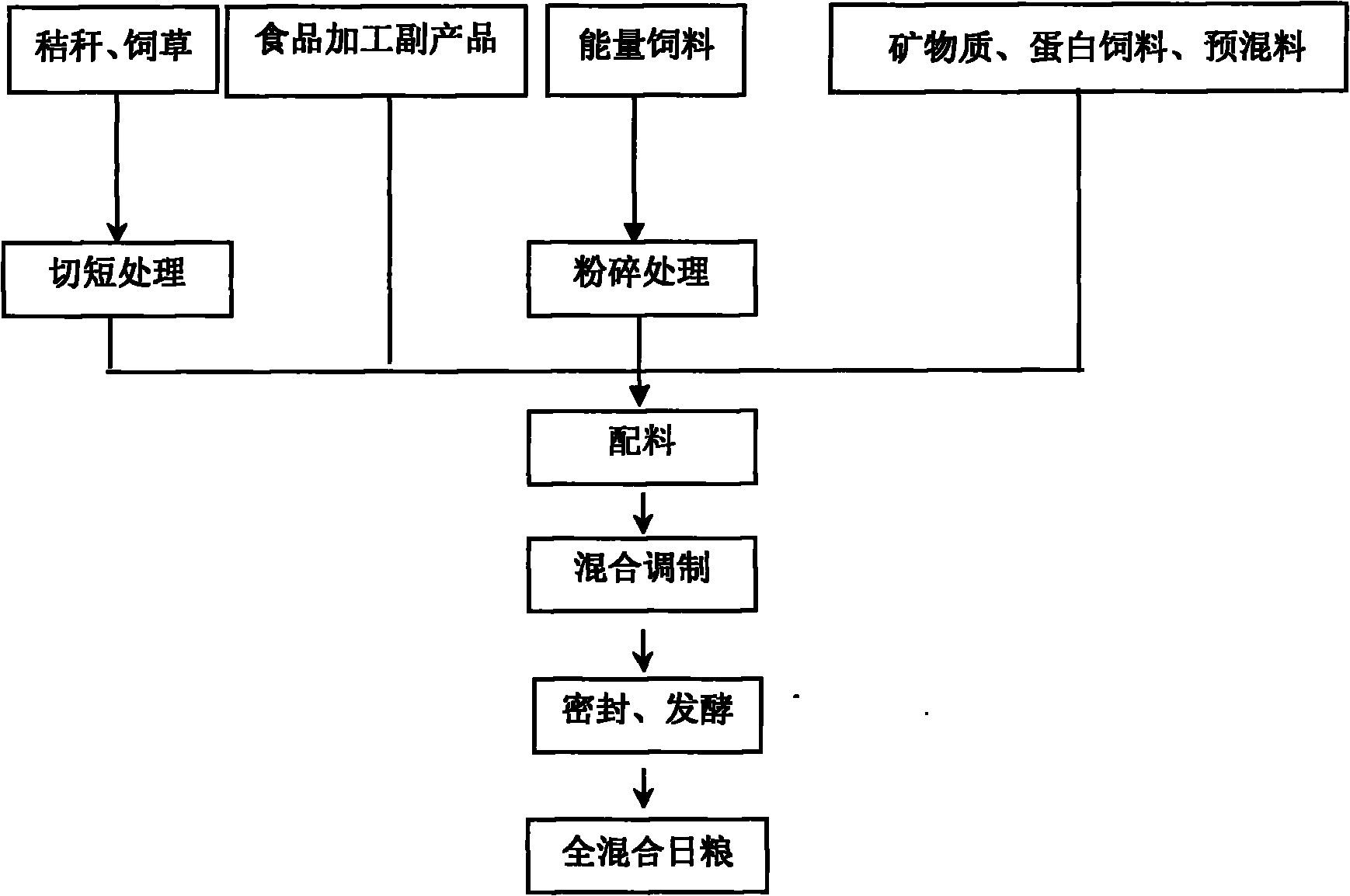

Method used

Image

Examples

Embodiment 1

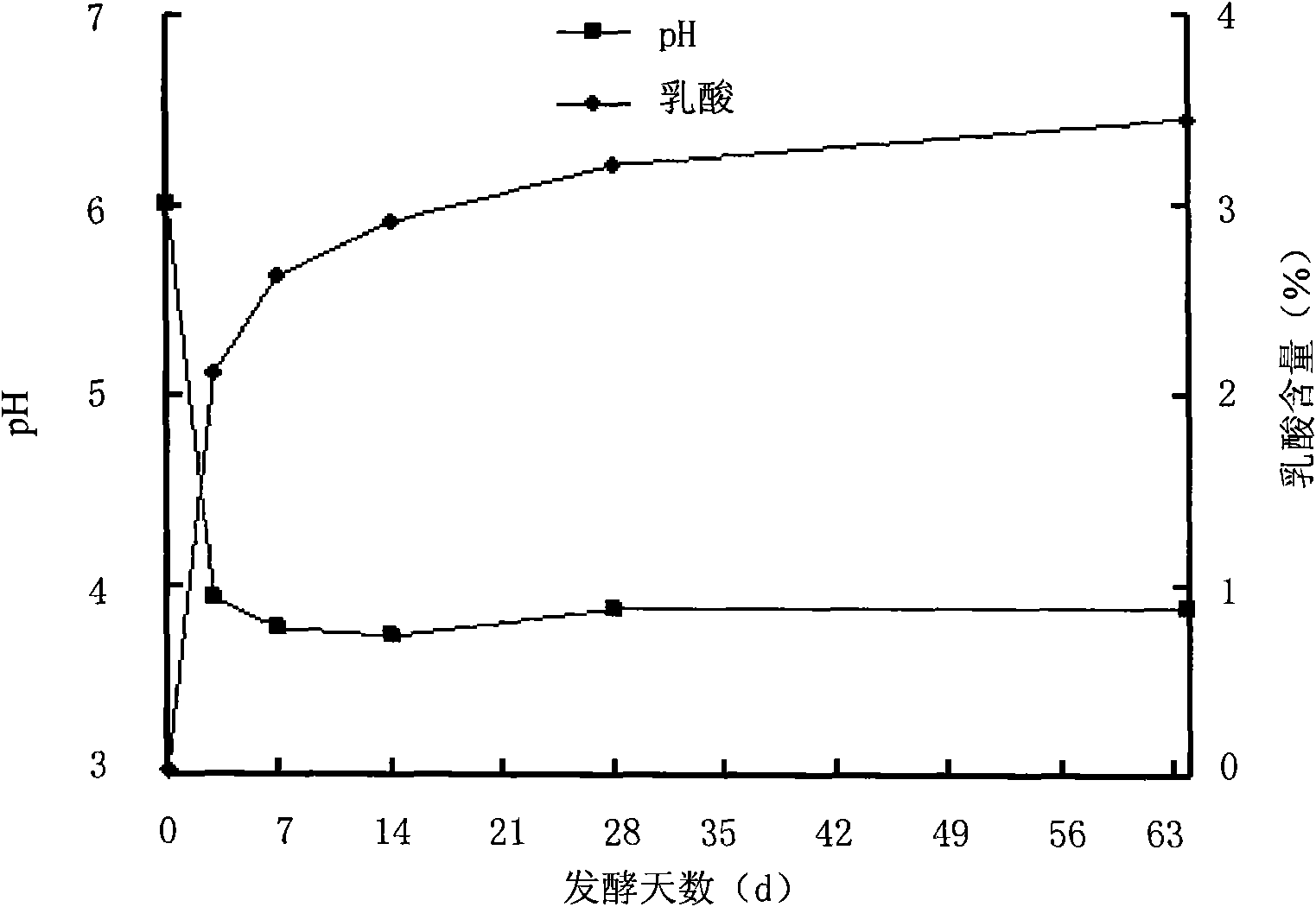

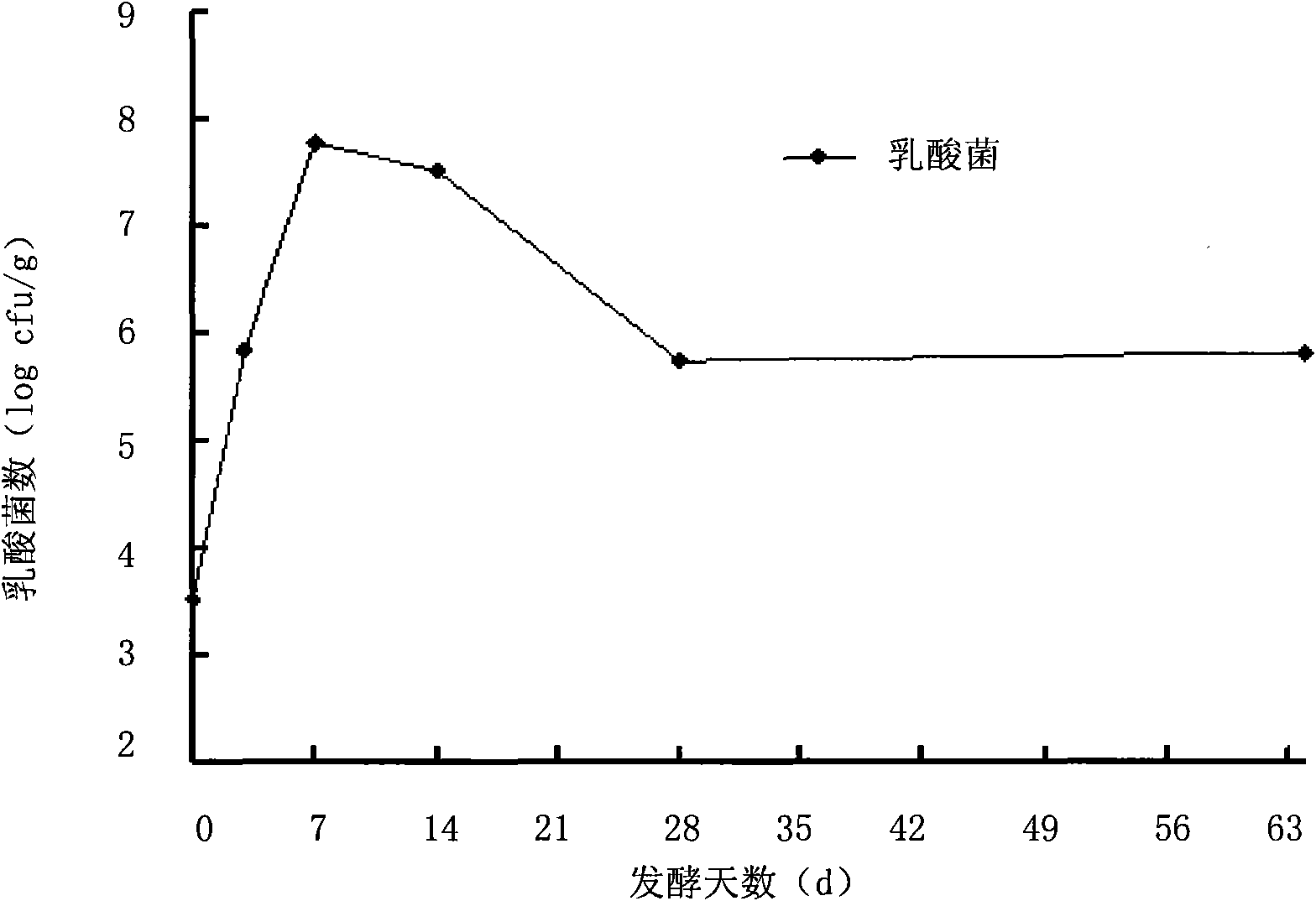

[0066] Preparation and fermentation performance measurement of embodiment 1, TMR

[0067] 1. Raw material composition

[0068] The raw material composition is shown in Table 1.

[0069] Table 1 Raw material composition and nutrient content

[0070]

[0071]

[0072] Contains 320,000 IU vitamin A and vitamin D per kilogram of premix 3 500000IU, vitamin E 1500IU, containing Zn 5.5g, Mn 6g, Cu 1.2g, Fe 8.5g, I 0.09g, Se 0.03g, Co 0.05g.

[0073] 2. Preparation of TMR and Determination of Fermentation Performance

[0074] 1. Pretreatment of raw materials

[0075] Straw and forage grass are cut with a forage grass cutter, and the length is controlled at about 10-30mm, or kneaded and cut with a kneading cutter. The energy feed is pulverized before use.

[0076] 2. Weigh each raw material according to the ratio in Table 1, and put them into the TMR mixer in order of specific gravity from small to large to mix evenly, and adjust the moisture content to 40%.

[0077] 3. Pu...

Embodiment 2

[0081] Preparation and aerobic stability detection of embodiment 2, TMR

[0082] 1. Pretreatment of raw materials

[0083] Straw and forage grass are cut with a forage grass cutter, and the length is controlled at about 10-30mm, or kneaded and cut with a kneading cutter. The energy feed is pulverized before use.

[0084] 2. Weigh each raw material according to the ratio in Table 1, and put them into the TMR mixer in order of specific gravity from small to large to mix evenly, and adjust the moisture content to 40%.

[0085] 3. Put the mixture obtained in step 2 into silage bags and seal them (500 g per bag), and obtain 6 sealed bags, which are randomly divided into two groups, one group is kept frozen, and the other group is fermented at room temperature (20-25° C.).

[0086] 4. Open the package on the 21st day, and thaw the first group at room temperature in advance; mix the samples of each group evenly and place them in an insulated and sterile open container, and analyze ...

Embodiment 3

[0088] Preparation and feeding effect analysis of embodiment 3, TMR

[0089] 1. Preparation of TMR

[0090] 1. Pretreatment of raw materials

[0091] Straw and forage grass are cut with a forage grass cutter, and the length is controlled at about 10-30mm, or kneaded and cut with a kneading cutter. The energy feed is pulverized before use.

[0092] 2. Weigh each raw material according to the ratio in Table 1, and put them into the TMR mixer in order of specific gravity from small to large to mix evenly, and adjust the moisture content to 40%.

[0093] 3. Wrap and seal the mixture obtained in step 2 with a silage wrapping machine (Takakita, Japan), and place it outdoors (minimum temperature 5° C., maximum temperature 25° C.) to ferment.

[0094] 4. Ferment for 21 days to obtain fermented TMR.

[0095] 2. Observe the external form of TMR

[0096] The color of TMR obtained after 21 days of fermentation is basically yellow, some of which are slightly brown, with a sour smell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com