Patents

Literature

50 results about "Optical molasses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical molasses is a laser cooling technique that can cool neutral atoms to temperatures lower than a magneto-optical trap (MOT). An optical molasses consists of 3 pairs of counter-propagating circularly polarized laser beams intersecting in the region where the atoms are present. The main difference between optical molasses and a MOT is the absence of magnetic field in the former. Therefore, unlike a MOT, an optical molasses provides only cooling and no trapping. While a typical Sodium MOT can cool atoms down to 300μK, optical molasses can cool the atoms down to 40μK, an order of magnitude colder.

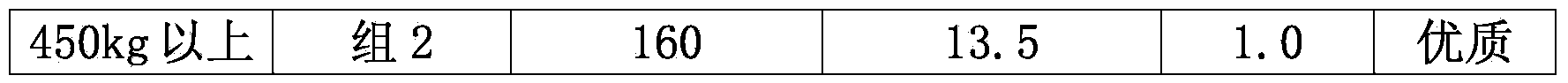

Low-concentrate type fermented total mixed ration for dairy cows and preparation method thereof

InactiveCN101828635ALow costIncrease contentFood processingAnimal feeding stuffAdditive ingredientTrace element

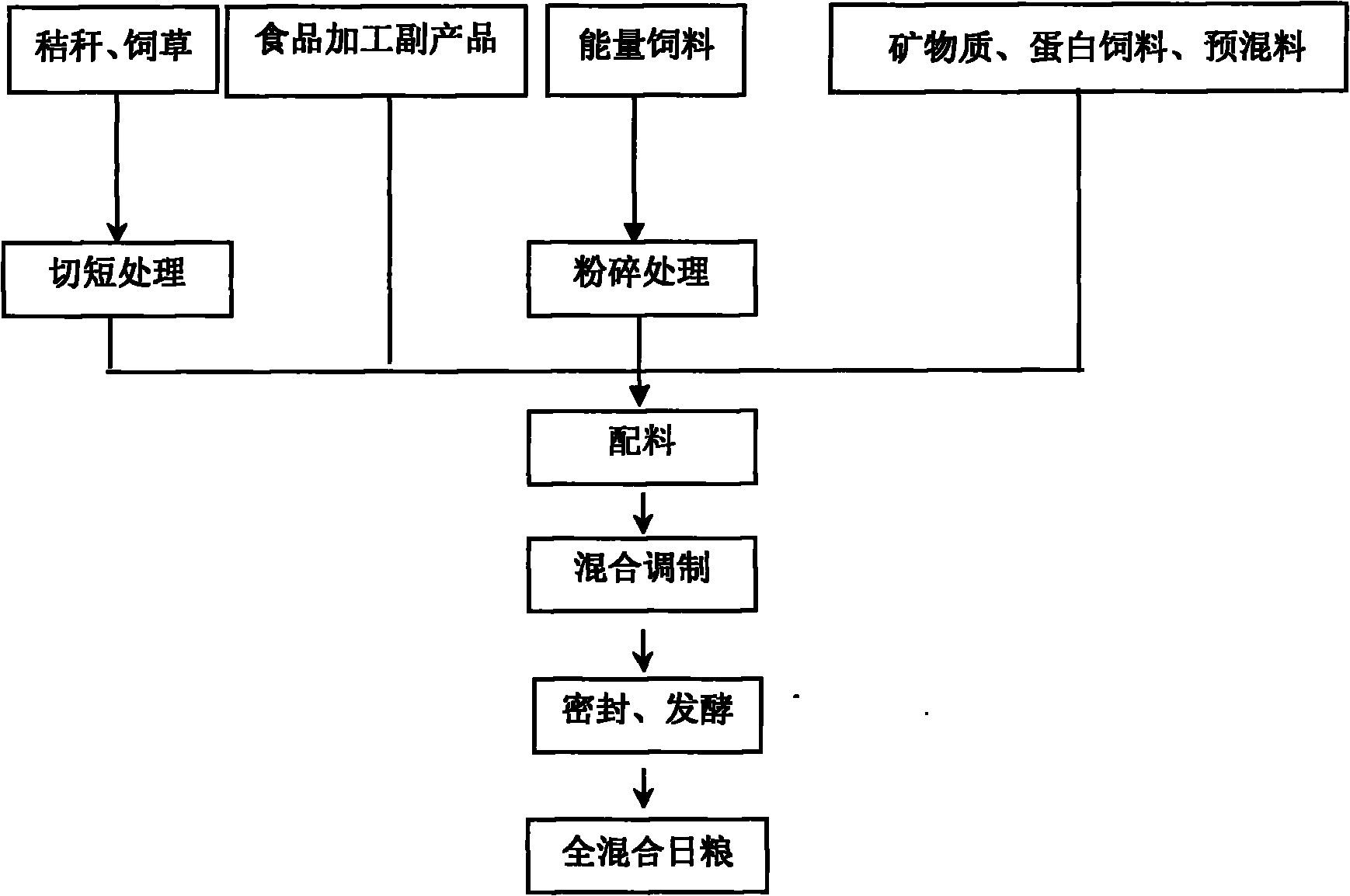

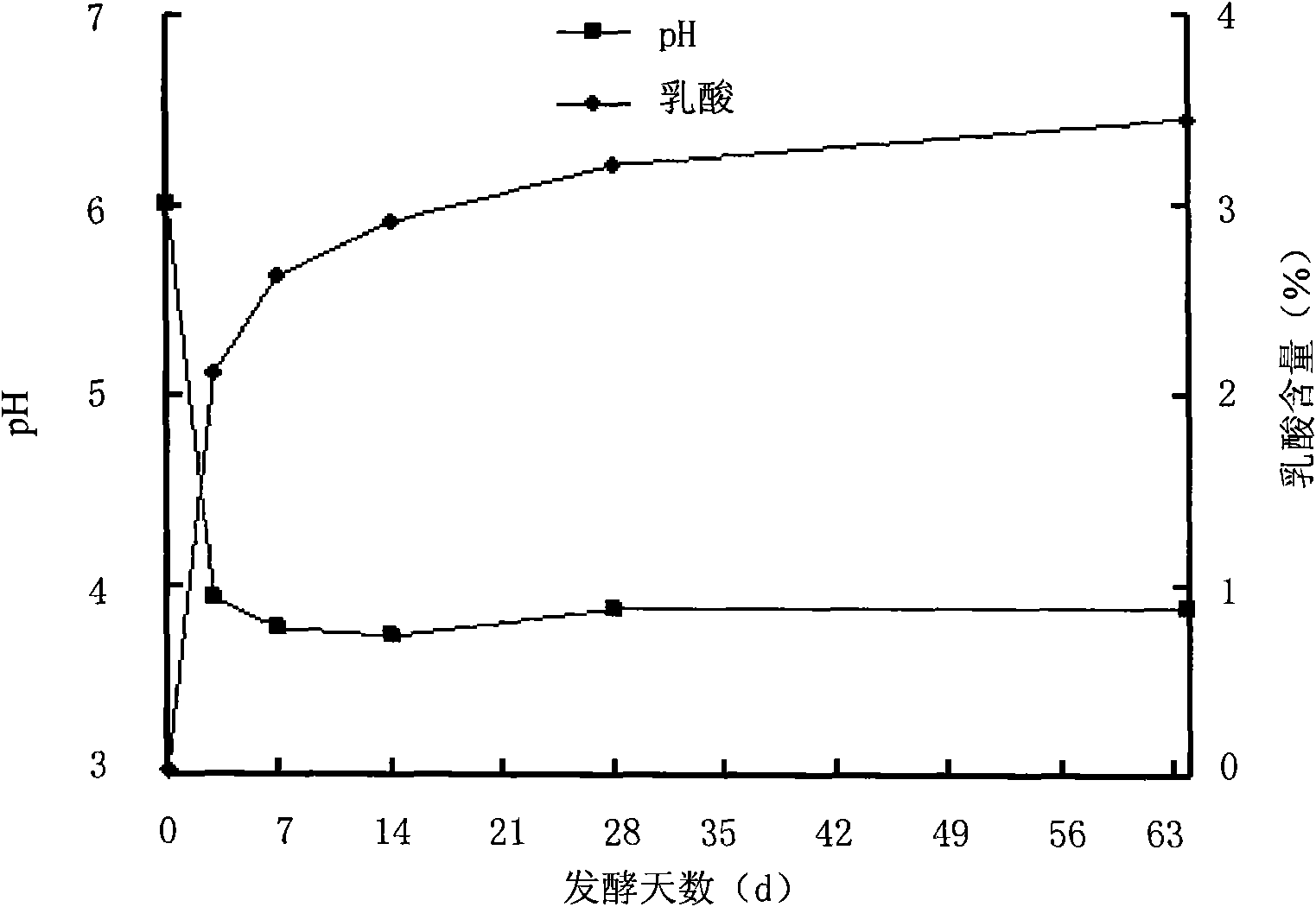

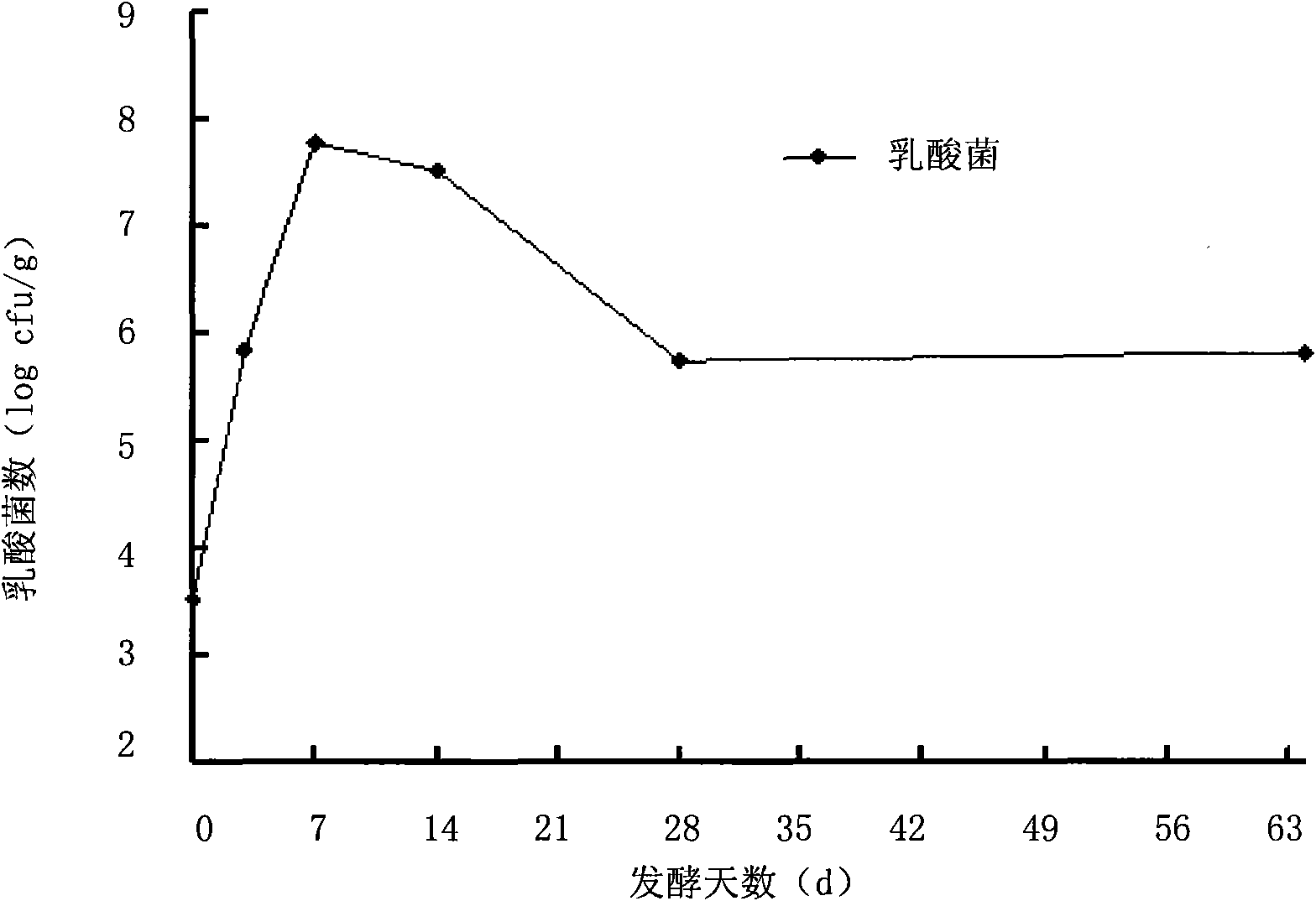

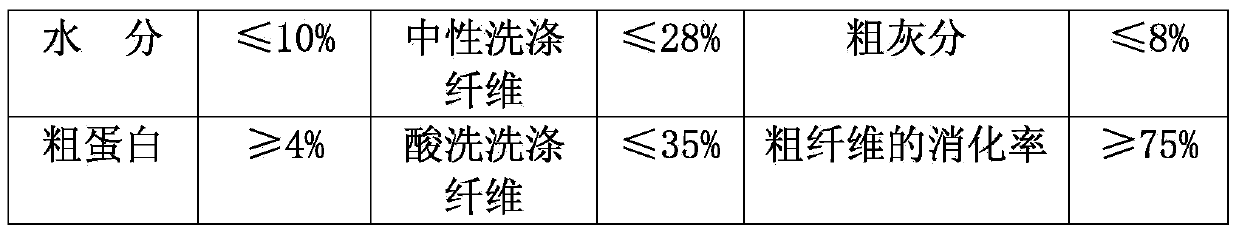

The invention discloses a low-concentrate type fermented total mixed ration (TMR) for dairy cows and a preparation method thereof. The TMR is prepared by the following steps of: (1) mixing the following materials in part by mass to obtain a mixture: 15 to 20 parts of straw, 4 to 8 parts of fodder grass, 6 to 12 parts of protein feed, 25 to 30 parts of energy feed, 3 to 6 parts of minerals and molasses, 40 to 45 parts of food processing by-products and 0.5 to 1 part of premix compound of trace elements and vitamins; (2) adjusting the moisture content of the mixture of the step (1) to be between 40 and 50 percent; and (3) sealing and fermenting the mixture of the step (2) for more than 14 days to obtain the ration for the dairy cows. The TMR of the invention has the following advantages of: low cost; complete nutrition and homogeneous components to avoid animal picky eaters and significantly improve the production performance of animals; and high aerobic stability. The low-concentrate type fermented total mixed ration for the dairy cows opens up a new technique and an effective way for efficient utilization of the resources of the straw and the food processing by-products, and has important practicability and application promotion values.

Owner:CHINA AGRI UNIV

Multifunctional biology aquatic feedstuff additive

ActiveCN101449744APurify the environmentReduce contentFood processingClimate change adaptationBiotechnologyWarm water

The invention provides a multifunctional biological activity aquatic product feed additive, which can be prepared by following steps: (1) uniformly mixing material; (2) adding a little warm water of 30-50 DEG C into molasses and uniformly mixing, adding composite bacterium and uniformly mixing, placing for 1-2 hours, and adding residual water to prepare composite bacteria liquid; (3) adding the composite bacteria liquid into the material, uniformly mixing, and carrying natural aerobic fermentation for 50-60 hours at room temperature; (4) drying the mixture until moisture is less than or equal to 10% under temperature less than 60 DEG C, and grinding package. Content of the multifunctional biological activity aquatic product feed additive provided by the present invention is more than 10<12>cfu / g, the aquatic product feed additive contains a large amount of chitooligosaccharides, alga oligosaccharides and active small peptide, and simultaneously contains a plurality of protease, lipase and amylase. The invention has advantages of simple production method, no need of special heating sterilization and fermentation equipment, less energy consumption and short fermentation period.

Owner:BEIJING GOLDENWAY BIO TECH

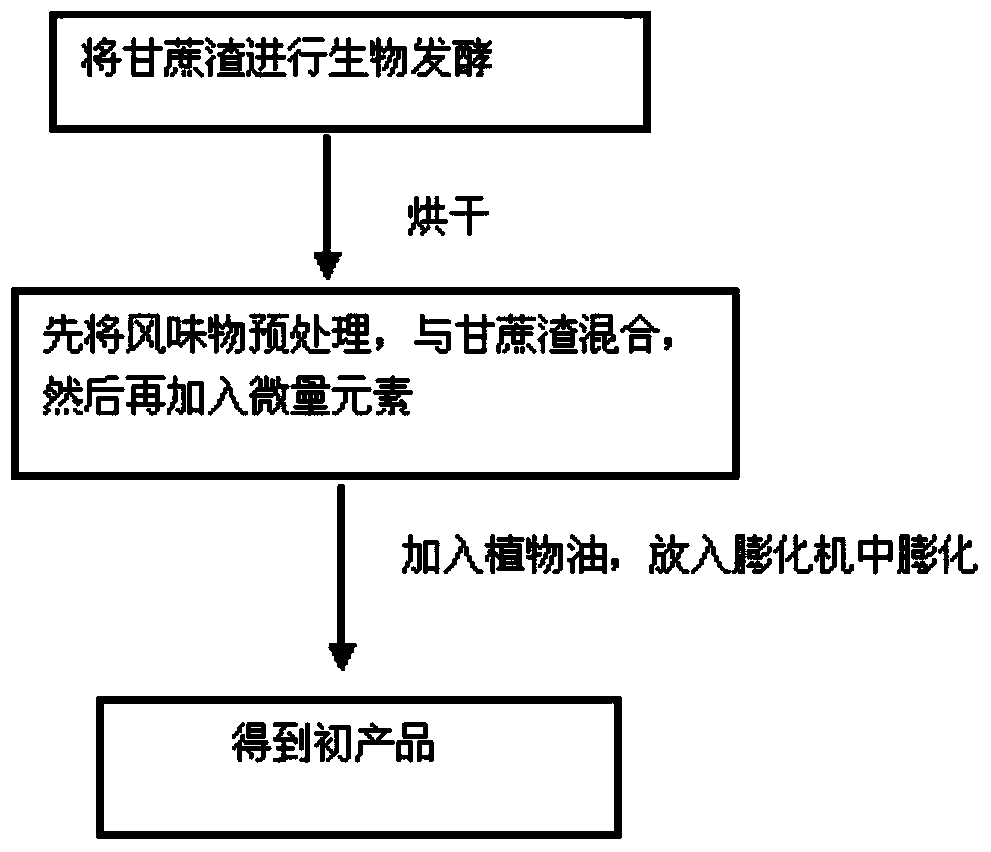

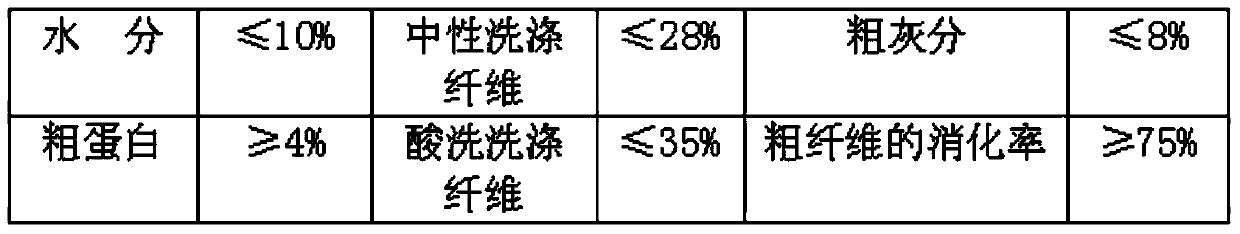

High-quality fiber feed using bagasse as main raw material and preparation method thereof

InactiveCN104171310AAddress critical shortagesSolve environmental problemsFood processingAnimal feeding stuffFiberVegetable oil

The invention discloses a high-quality fiber feed using bagasse as a main raw material. The feed is characterized by being prepared from the following raw materials in parts by weight: 70-100 parts of bagasse, 5-10 parts of molasses, 5-10 parts of flavors, 5-20 parts of vegetable oil, 1-2 parts of probiotics and 2-3 parts of bio-enzyme; and the feed is prepared through the steps of biological treatment, dehydration, puffing, sizing and the like. The maximum value of the feed lies in that the high-quality fiber feed with high utilization rate, good palatability and high cost performance is produced for herbivore and industrialized by using the bagasse (which is main raw material), molasses, food industry leftovers and the like with low value as raw materials, so that the problem of serious shortage of high-quality coarse feeds in South China is solved, and the purpose of environment friendliness in sugar enterprises and food production enterprises is also achieved.

Owner:陈学文

Preparation method of biological feed of banana stem leaves

InactiveCN101579041AHas a clear fragranceLower pHFood processingAnimal feeding stuffBiotechnologyFully developed

The invention discloses a preparation method of a biological feed of banana stem leaves, which comprises the following steps of: cutting up the banana stem leaves, then pre-drying till the water content is 70 to 75 percent, adding minor ingredients into the banana stem leaves, then adding cellulase, tannase and third class seed liquid of lactobacillus plantarum, mixing evenly, extracting air, sealing, storing and preparing to obtain the biological feed of banana stem leaves; and the minor ingredients are pineapple peels, papaya peels or molasses. The preparation method uses the banana stem leaves as major raw materials, generates an acid environment by fermentation of lactobacillus to inhibit spoilage micro-organisms, and can fully develop and utilize by products of fruits, reduce tannin content and coarse fibre content of the by product of banana and improve the palatability, digestibility and nutritional value of the feed.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI +1

High-energy plant-eating animal feed containing molasses as well as preparation method thereof

InactiveCN104026330AAvoid the Maillard reactionHigh nutritional valueFood processingAnimal feeding stuffHigh energyFodder

The invention discloses a high-energy plant-eating animal feed containing molasses. The high-energy plant-eating animal feed containing molasses is characterized by being prepared from the following raw materials in parts by weight: 45-55 parts of molasses, 42-52 parts of vector, 1-2 parts of probiotics and 1-2 parts of bio-enzyme, and prepared by the steps of drying, fermenting, stirring, mixing and the like. The high-energy plant-eating animal feed containing molasses, which is provided by the invention, is convenient to use, has good adhesion performance, can be loosened easily, can be eaten by plant-eating animals directly, also can be mixed with other feeds, is capable of improving the dietary energy level greatly and increasing the dry matter intake of dairy cattle, and also has the effect of activating the number and activity of rumen microorganisms, thereby improving the feed digestibility.

Owner:陈学文

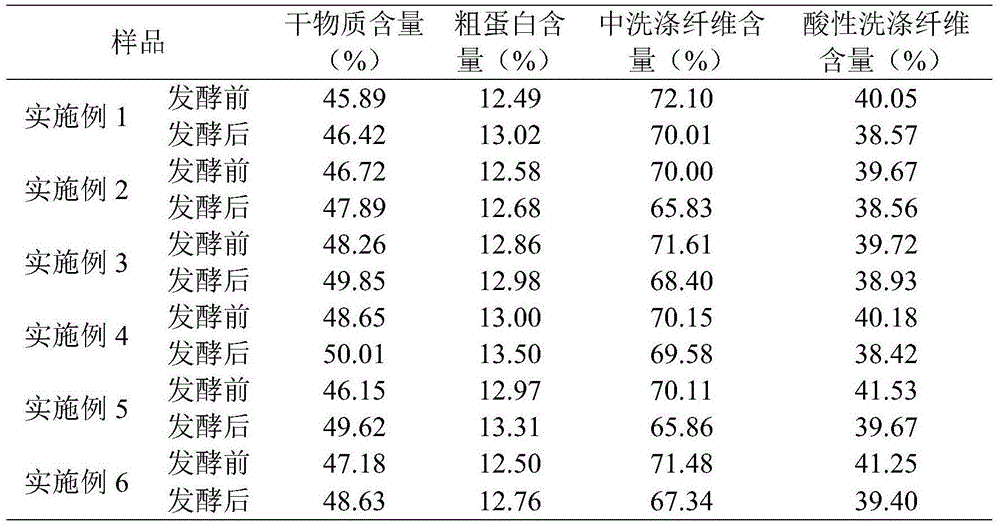

Biological feed for sheep and preparation method thereof

InactiveCN104054967AImprove digestibilityPromote fermentationFood processingAnimal feeding stuffDiseaseAnimal science

The invention provides a biological feed for sheep. The feed comprises the following components by weight: 40-60 parts of bagasse, 10-15 parts of dry cassava dregs, 10-15 parts of sugar cane tail leaf, 1-2 parts of dicalcium phosphate, 4-6 parts of urea, 4-6 parts of molasses and 0.4-0.9 parts of a feed additive. The invention also provides a preparation method of the biological feed for sheep. The biological feed for sheep provided by the invention makes full use of raw materials including waste bagasse, sugarcane tail leaf and cassava dregs, which are not originally consumed by the sheep; through the fermentation of microorganism, the feed has enhanced palatability and is easy for sheep to eat; the feed improves the utilization rate of nutrient contents and improves digestion capability of the sheep; the fermented feed contains a large amount of beneficial microorganisms and nutrients for the growth of sheep; and sheep fed with the feed has enhanced disease resistance and improved lamb quality and taste.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI

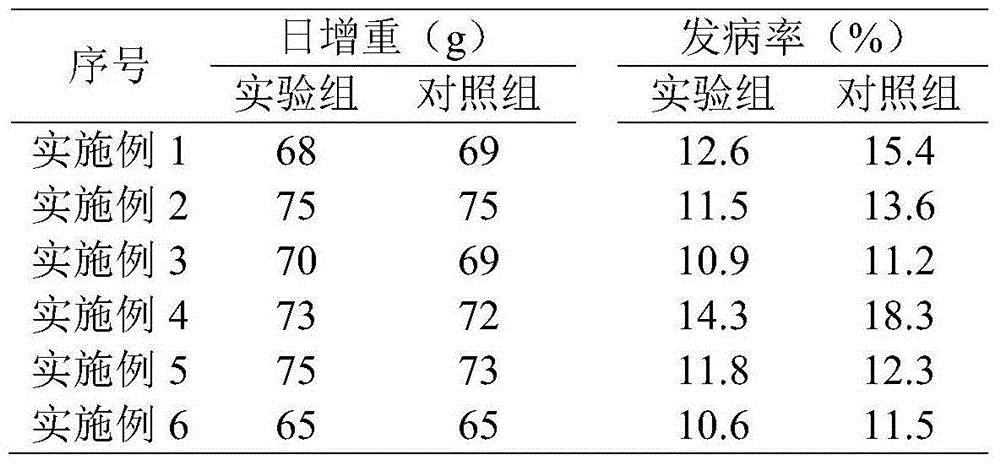

Process for manufacturing animal feed supplements

InactiveUS7045165B2More productiveIncrease productionMilk preservationFood processingAdditive ingredientFeed additive

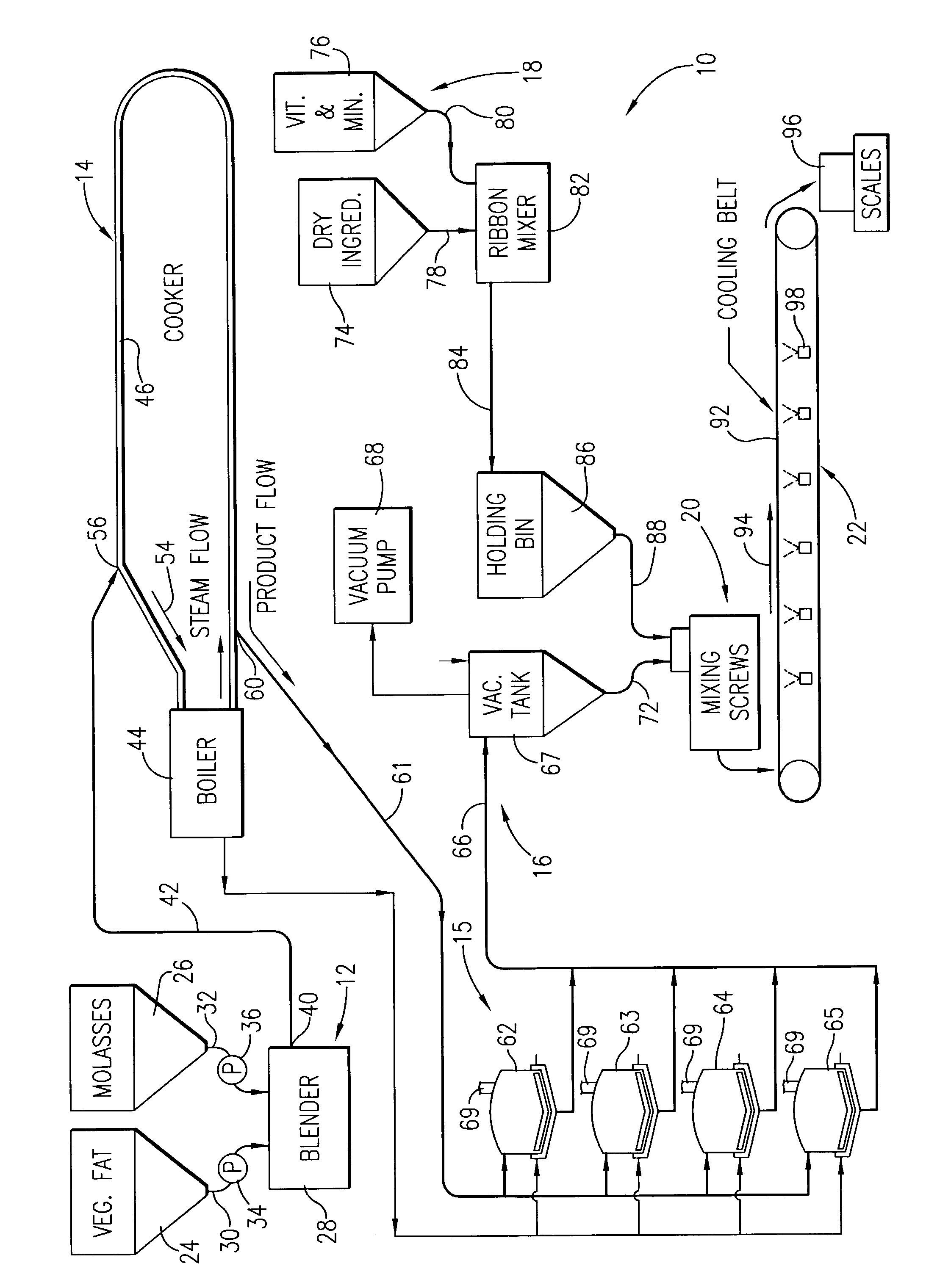

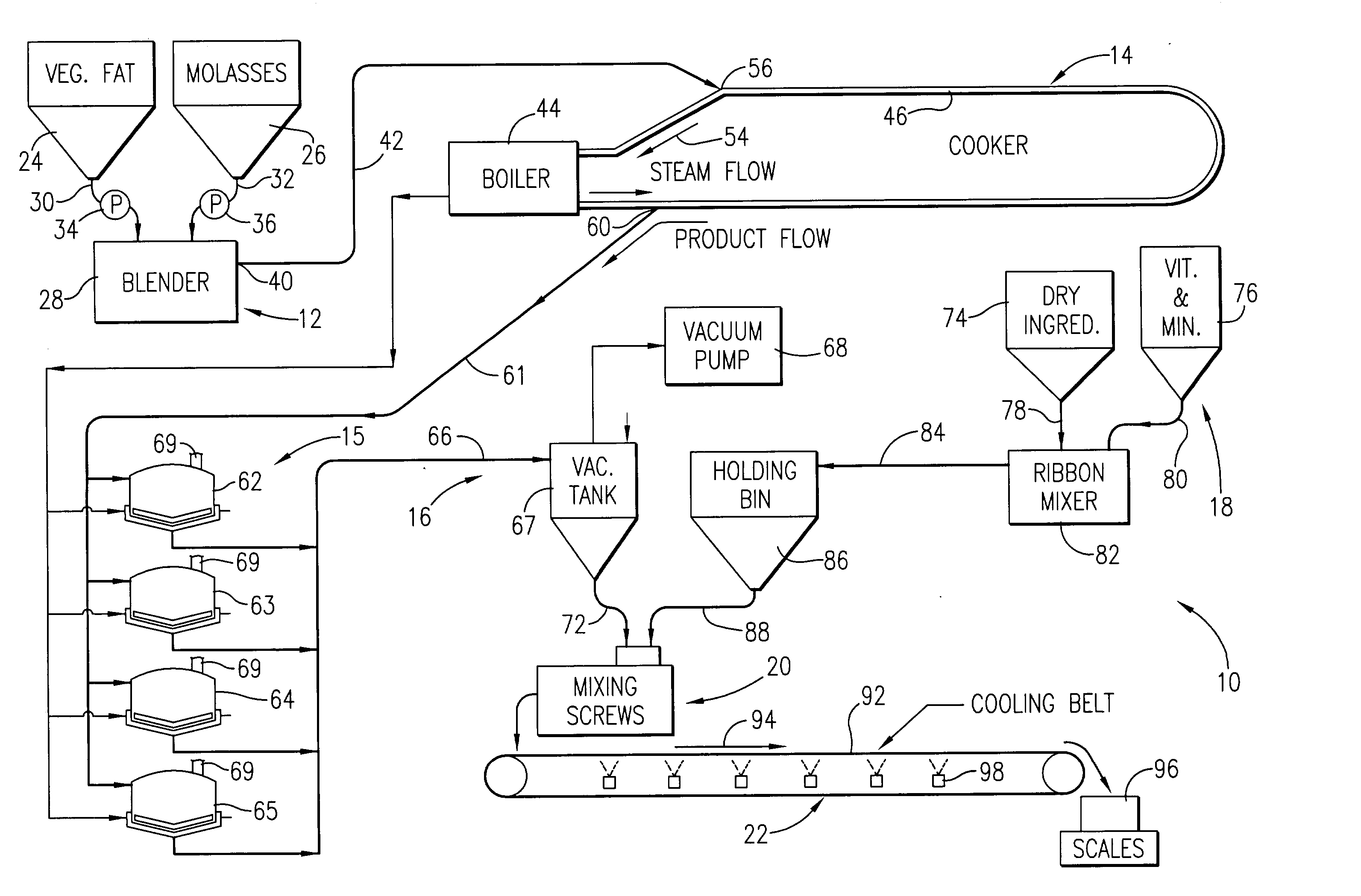

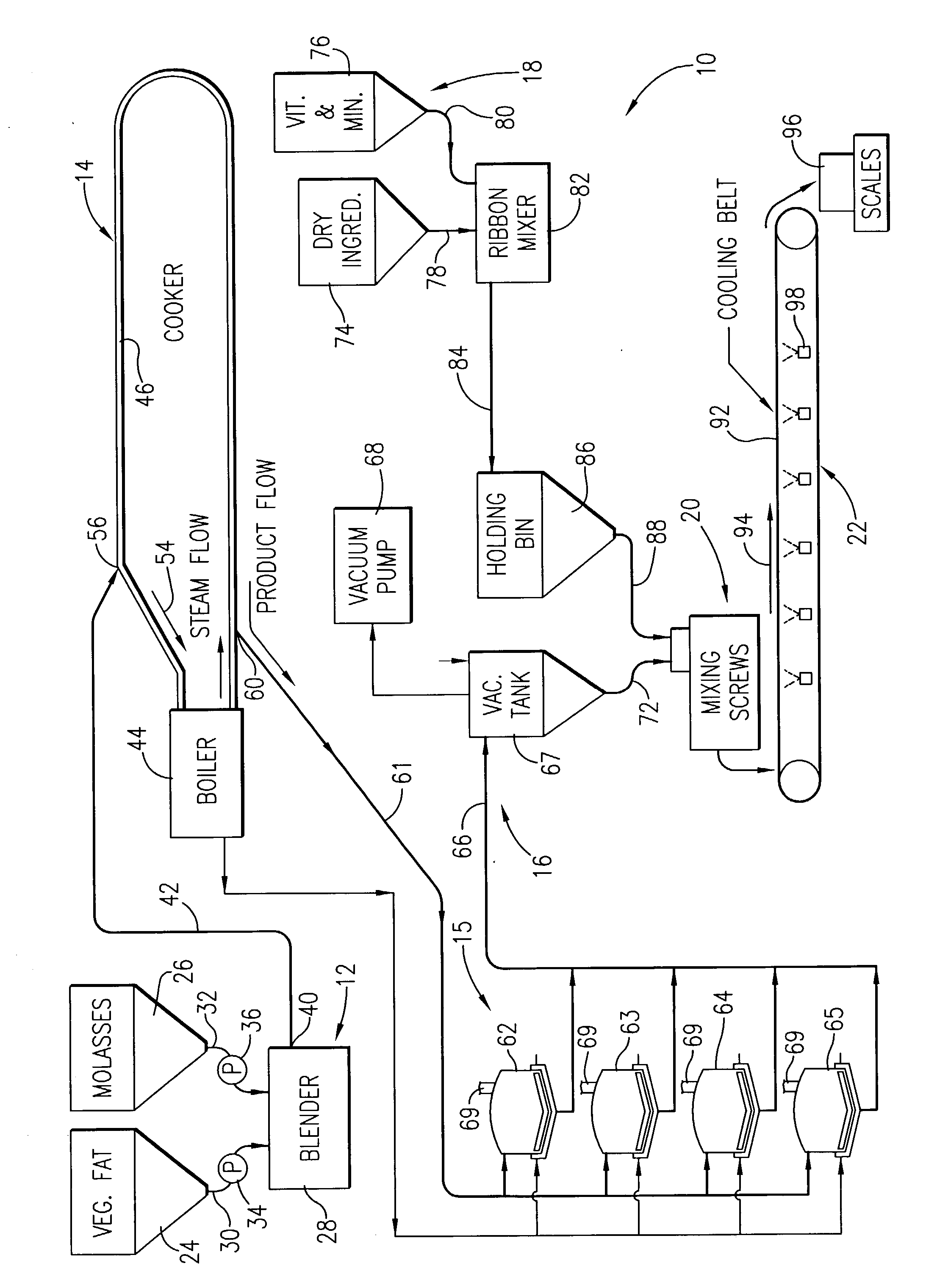

An improved, continuous process for the production of animal feed supplements including an apparatus for carrying out such process is provided. Broadly, the process includes continuous preparation of a preblend including molasses and vegetable fat, followed by continuous cooking of the preblend in an elongated cooking zone and batch cooking assembly. The cooked preblend is then continuously treated for removal of moisture and partial cooling thereof, whereupon dry ingredients (e.g., vitamins and protein sources) are added and the resultant feed supplement is continuously cooled and packaged.

Owner:ANIMAL FEED SUPPLEMENT

Process for manufacturing animal feed supplements

An improved, continuous process for the production of animal feed supplements including an apparatus for carrying out such process is provided. Broadly, the process includes continuous preparation of a preblend including molasses and vegetable fat, followed by continuous cooking of the preblend in an elongated cooking zone and batch cooking assembly. The cooked preblend is then continuously treated for removal of moisture and partial cooling thereof, whereupon dry ingredients (e.g., vitamins and protein sources) are added and the resultant feed supplement is continuously cooled and packaged.

Owner:ANIMAL FEED SUPPLEMENT

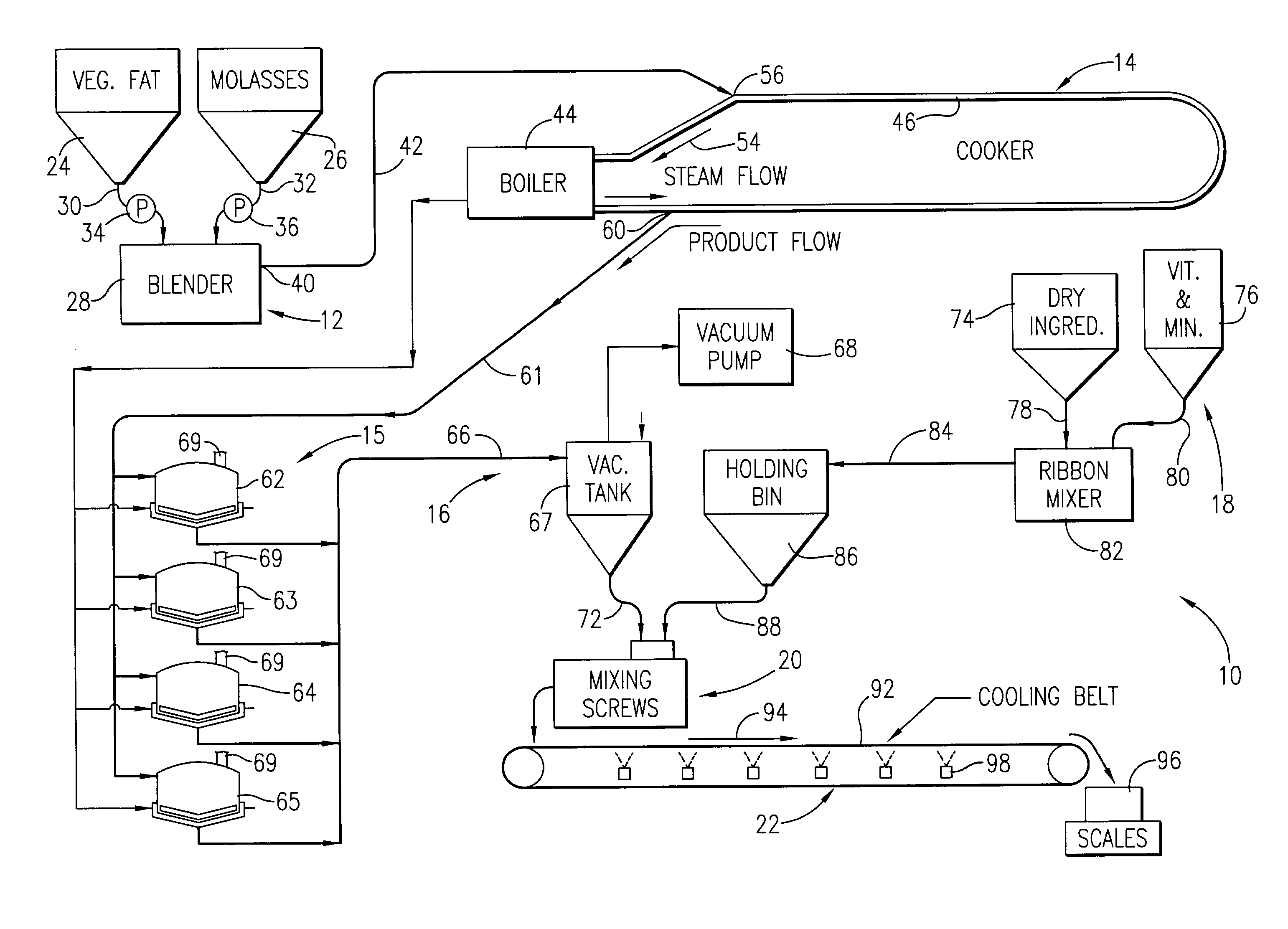

Cattle and sheep fattening barbary wolfberry fruit and licorice root health-care licking brick and preparation method thereof

InactiveCN101606640AChoose from a wide range of sourcesLow priceFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep fattening barbary wolfberry fruit and licorice root health-care licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.21-0.35g of ferrous sulfate, 0.21-0.35g of zinc sulfate, 0.14-0.21g of copper sulfate, 0.24-0.35g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.07-0.35g of potassium iodide, 0.03-0.07g of cobalt chloride, 0.14-0.35g of magnesium oxide, 6.0224-8.038g of chromium nicotinate, 30-150g of sodium sulfate, 200-300g of common salt, 200-300g of bentonite, 30-60g of molasses, 190-285g of barbary wolfberry fruit and 50-100g of licorice root. The preparation method combines the chemical coagulation technology and the mechanical pressing technology, simultaneously targets the characteristics of cattle and sheep fattening and develops the nutrition licking brick which adds the barbary wolfberry fruit and the licorice root and supplements cattle and sheep complex nutrition, thereby fully playing good properties of cattle and sheep. The licking brick is characterized by a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety, environmental protection and the like, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

All-natural composition and method for repelling and killing insects

InactiveUS20080311215A1Safely applied to human skinSafely to hairBiocideAnthropod material medical ingredientsAdditive ingredientPeppermints

An all-natural composition can be used to repel or kill insects. The composition is an aqueous solution or mixture of available non-toxic ingredients. These include a weak acid to lower the pH, and one or more aromatics. The ingredients include one or more herbal essential oils, such as rosemary oil, peppermint oil, or a blend; a natural aqueous sugar extract or extracts, such as honey and / or molasses; a fragrance; and a natural weak acid solution, such as apple cider vinegar and / or lemon juice. The composition can be applied to dogs, horses, or other pets. The composition is also effective on hair and skin to combat the effects of swimming pool chlorine.

Owner:GRACE CATHERINE A

Method for curing liquid condition molasses

InactiveCN101185487AEasy to transportEasy to storeFood preparationLiquid statePulp and paper industry

The invention relates to a solidifying method of liquid molasses, which pertains to the oils and foodstuffs processing field, and is a technique of leading liquid molasses to be processed into molasses lump or molasses powder. The molasses is firstly grinded and filtered, and equipment adopted is a roller scraping plate dryer. The filtered liquid molasses is splashed on the outer surface of a roller of the roller scraping plate dryer; the molasses is scraped off by the scraping plate after dried and processed to be molasses lump or molasses powder after cooled. The temperature on the outer surface of the roller is controlled between 60 DEG C and 160 DEG C. Technique of the invention can change liquid molasses into solid molasses continuously, and the water content is changed into 3 percent to 9 percent from 30 percent to 70 percent. The invention has low cost, with which liquid molasses can be further processed to molasses lump or sacked molasses powder, thus facilitating transportation, storage and use of the molasses.

Owner:ANYANG MANTIANXUE PROTEIN

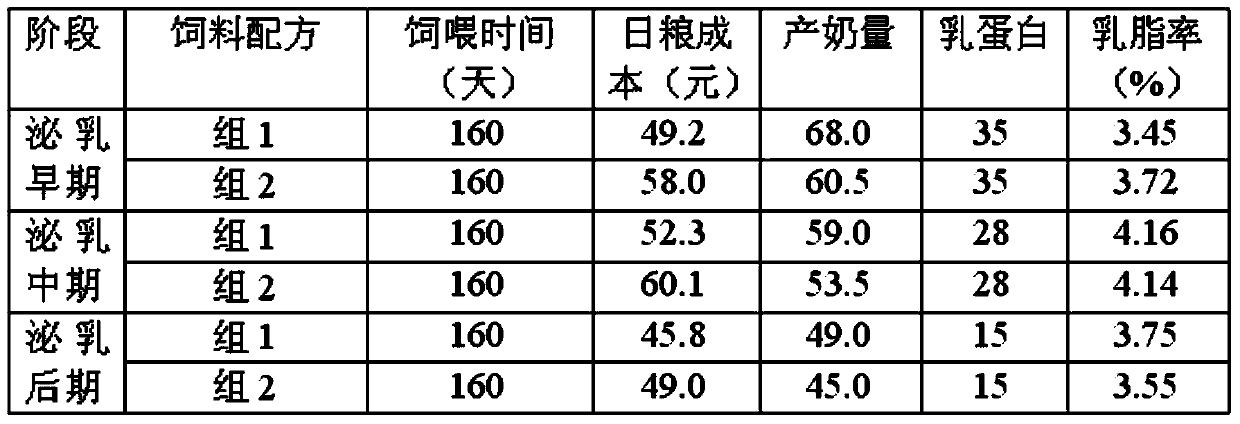

Ruminant animal feed and preparation method thereof

InactiveCN104186939AAvoid pollutionImprove immunityFood processingAnimal feeding stuffVegetable oilFermentation

The invention discloses a ruminant animal feed which is characterized by being prepared from the following raw materials in part by weight: 80-150Kg of bagasse, 30-50Kg of flavoring substances, 10-50Kg of vegetable oil, 1-3Kg of a microorganism preparation, 1-5Kg of bio-enzyme and 1-5Kg of trace elements, and is prepared by the steps of fermentation, pretreatment, puffing and the like. According to the ruminant animal feed, discarded honey, discarded fruit peels and the like are recycled to be used as the flavoring substances, so that the palatability of the animal feed is greatly improved, and the multi-flavor feed is supplied to the ruminant animals; furthermore, the feed is low in investment, safe and free from toxicity, can be stored for a long time and can be supplied all the year round; the problem of shortage of grass feeds in winter is solved.

Owner:卓礼仕

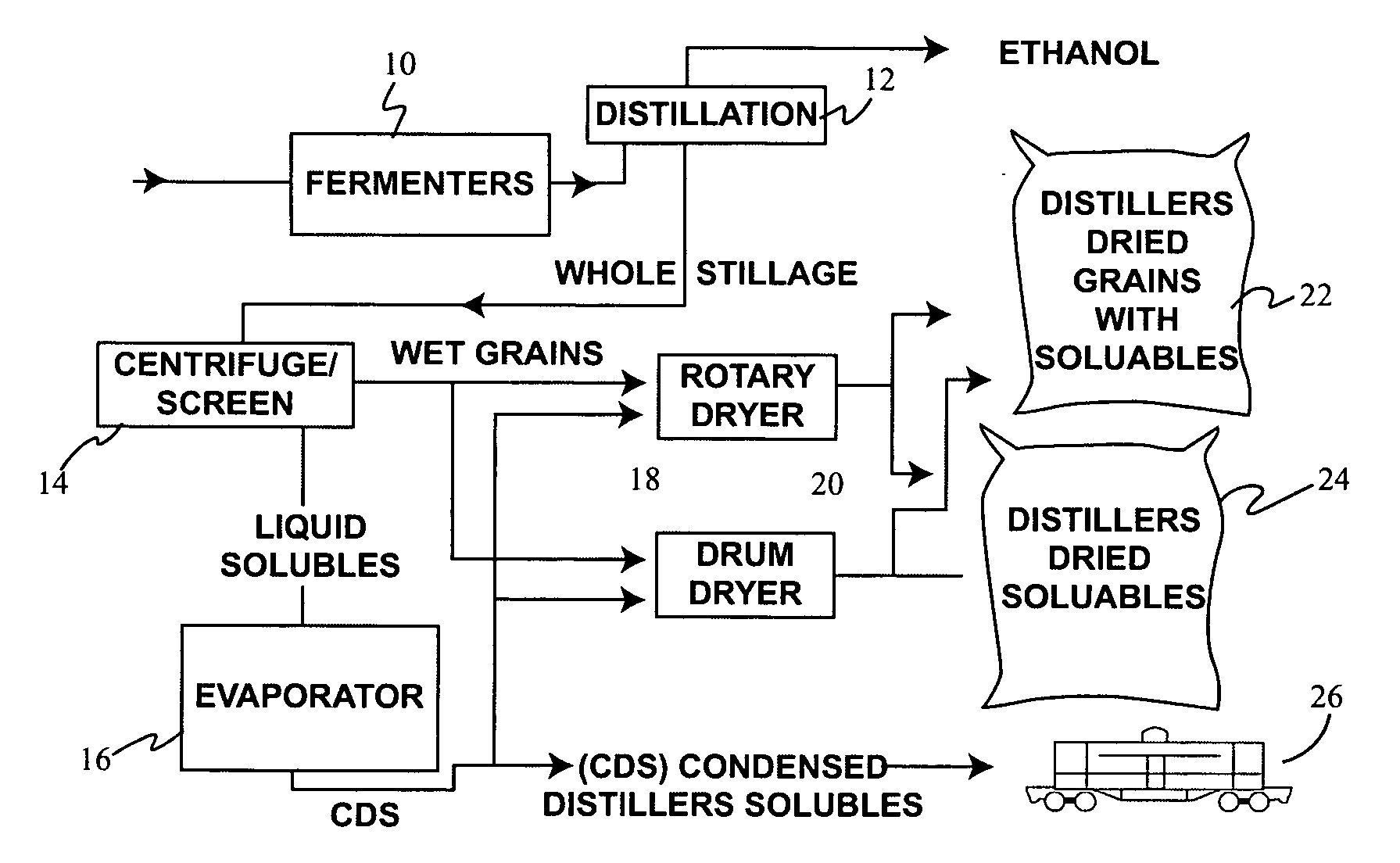

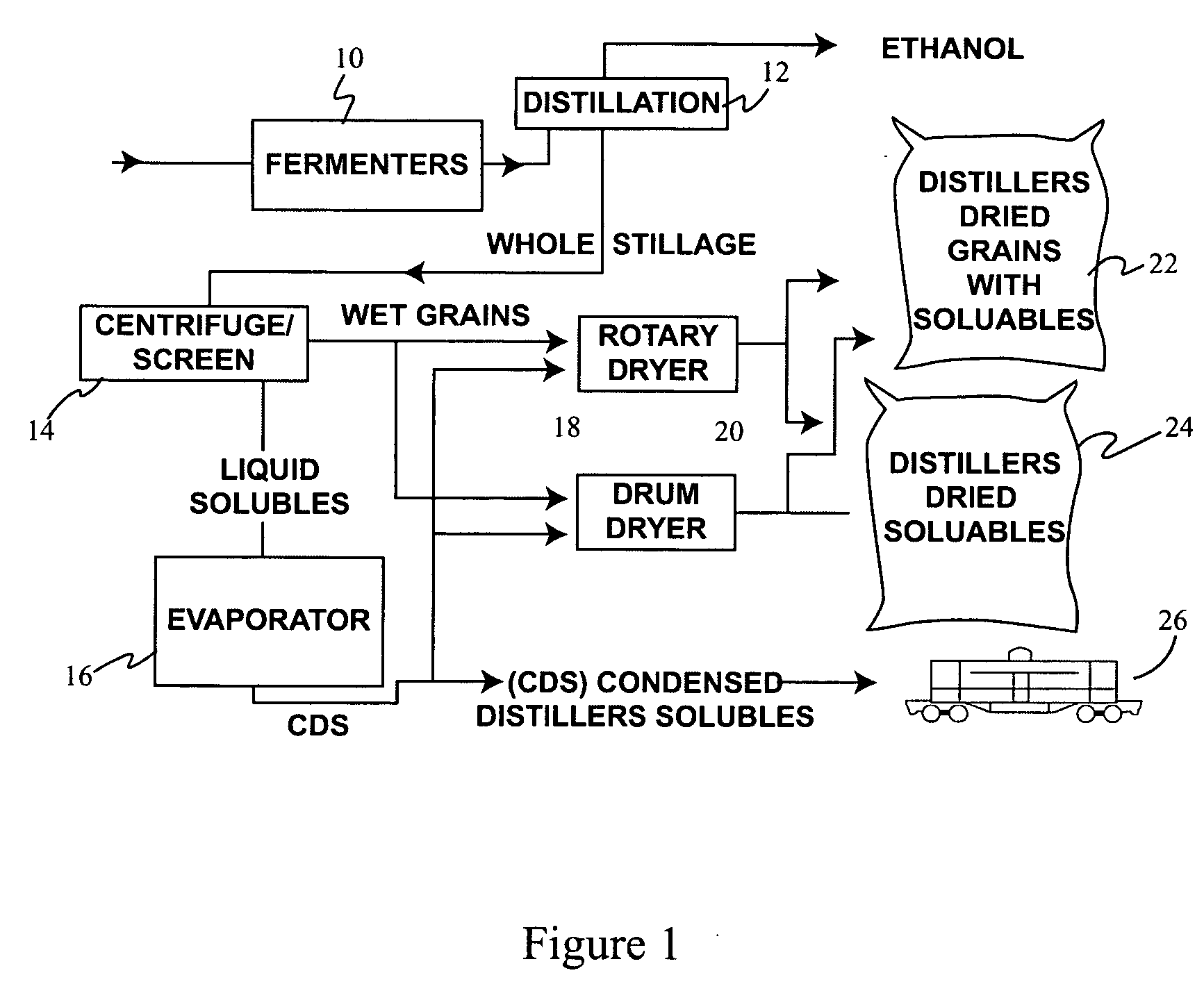

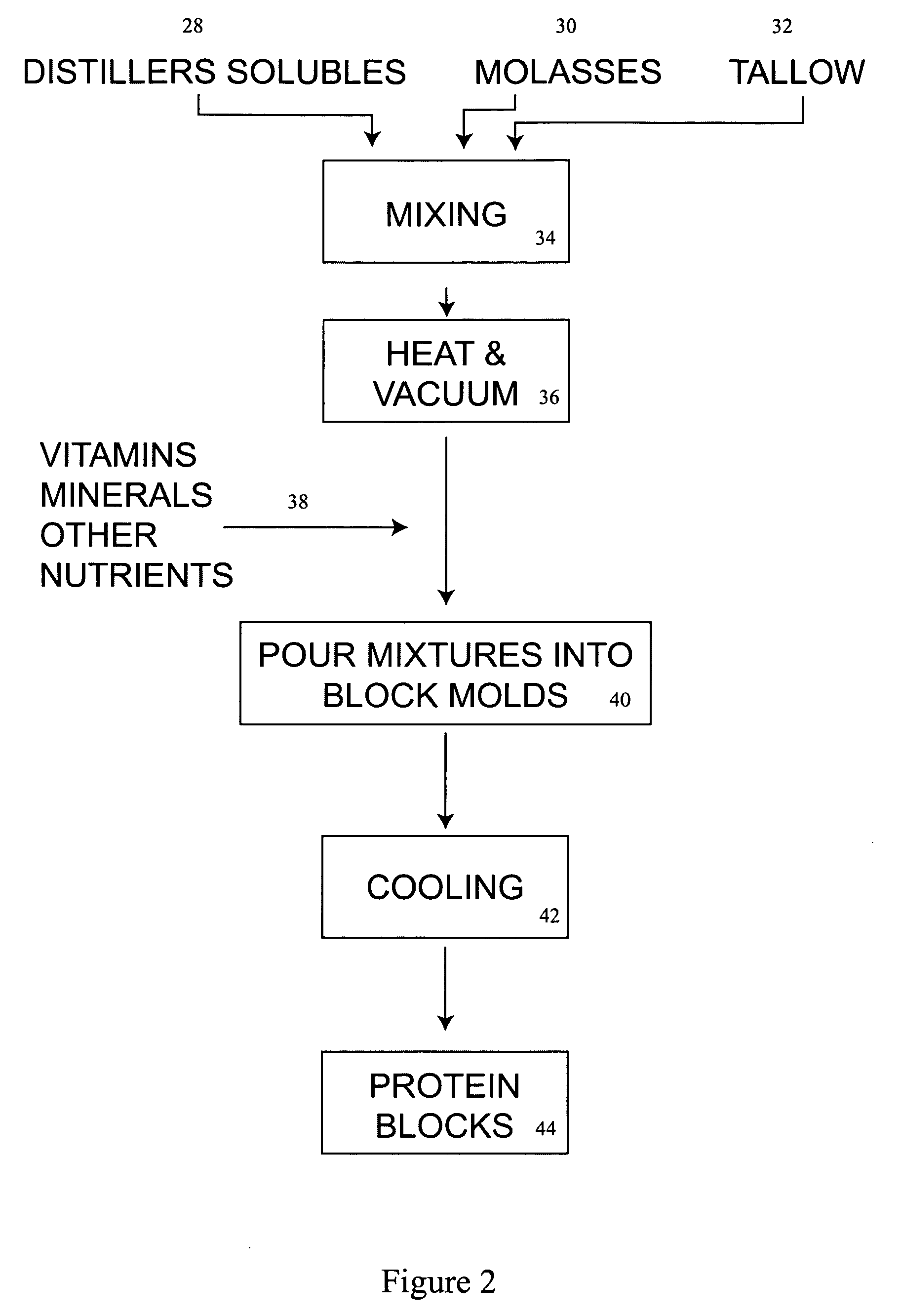

Distillers solubles as the primary constituent in protein blocks for livestock

This invention is a method for making protein blocks for livestock feeding by mixing together distillers solubles, molasses, and tallow, wherein the distillers solubles constitute the primary ingredient in the protein block and the molasses are only a minor constituent of said protein block; removing water from the mixture of distillers solubles, molasses, and tallow using heat and vacuum, so as to condense the mixture; combining the condensed mixture of distillers solubles, molasses, and tallow with premixtures of vitamins, minerals, and other nutrients; pouring the combination of condensed distillers solubles, molasses, and tallow plus nutrient premixtures into molds while the combination is still hot; and cooling the combination to form a protein block.

Owner:NAT CORN GROWERS ASSOC

Technology for preparing feed of flocks and herds by taking sugarcane tops or bagasse as raw material

ActiveCN103404744AReduce feeding costsIncrease incomeFood processingAnimal feeding stuffPastoralismHerd

Owner:刘运宁 +1

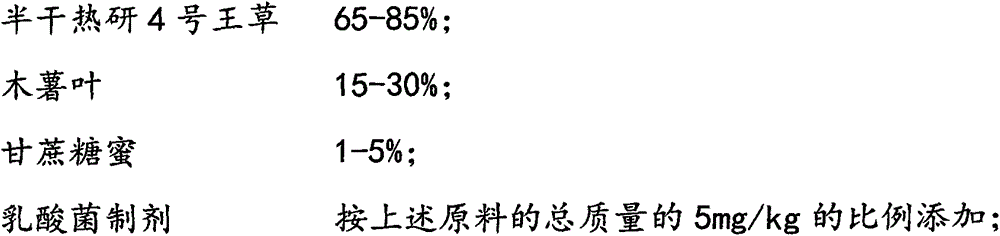

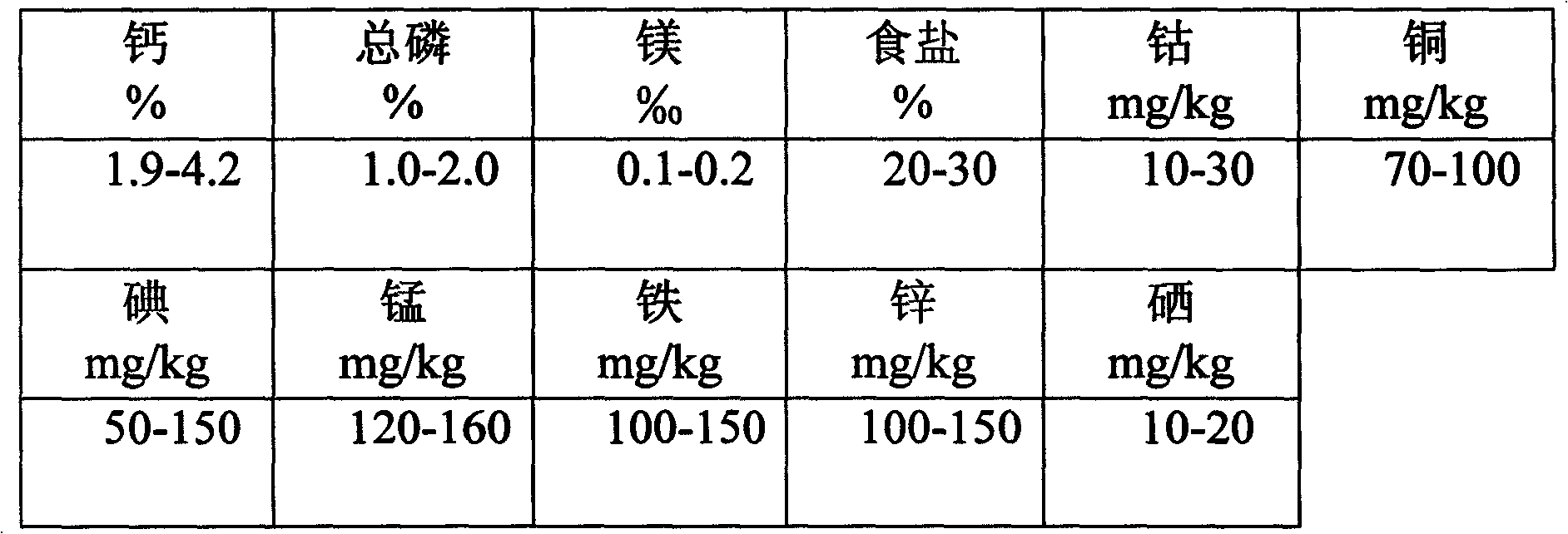

Silage with mixed Reyan No.4 Chinese sugarcane and cassava leaves and ensiling method

InactiveCN104824361ALower pHReduce ammonium nitrogen contentAnimal feeding stuffAnimal fodder preservationAdditive ingredientDry heat

The invention discloses silage with mixed Reyan No.4 Chinese sugarcane and cassava leaves and an ensiling method. The silage comprises the following components by weight percent: 65-85% of half-dry Reyan No.4 Chinese sugarcane, 15-30% of cassava leaves, 1-5% of cane molasses and 5mg / kg of a lactic acid bacteria preparation which is added based on the total weight of the raw materials, wherein the Reyan No.4 Chinese sugarcane is the Reyan No.4 Chinese sugarcane with the water content of 65-70%, and the cassava leaves are fresh harvested cassava leaves; the lactic acid bacteria preparation consists of lactobacillus plantarum. According to the invention, the pH value and the content of ammonium nitrogen of the silage are reduced, the content of lactic acid is improved, and the silage quality is obviously improved; the content of proteins of the silage is improved, the content of fiber components is reduced, and the nutritional value of the silage with the Reyan No.4 Chinese sugarcane is improved; the ensiling method is simple and effective to operate and has significance on solving of imbalance of coarse feed resource supply and reasonable utilization of byproducts of economical crops.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI

Ruminant beet pulp-urea particle feed

InactiveCN102178099AIncreased average milk yieldPrevent uneven colorFood processingAnimal feeding stuffMastitisSodium sulfate

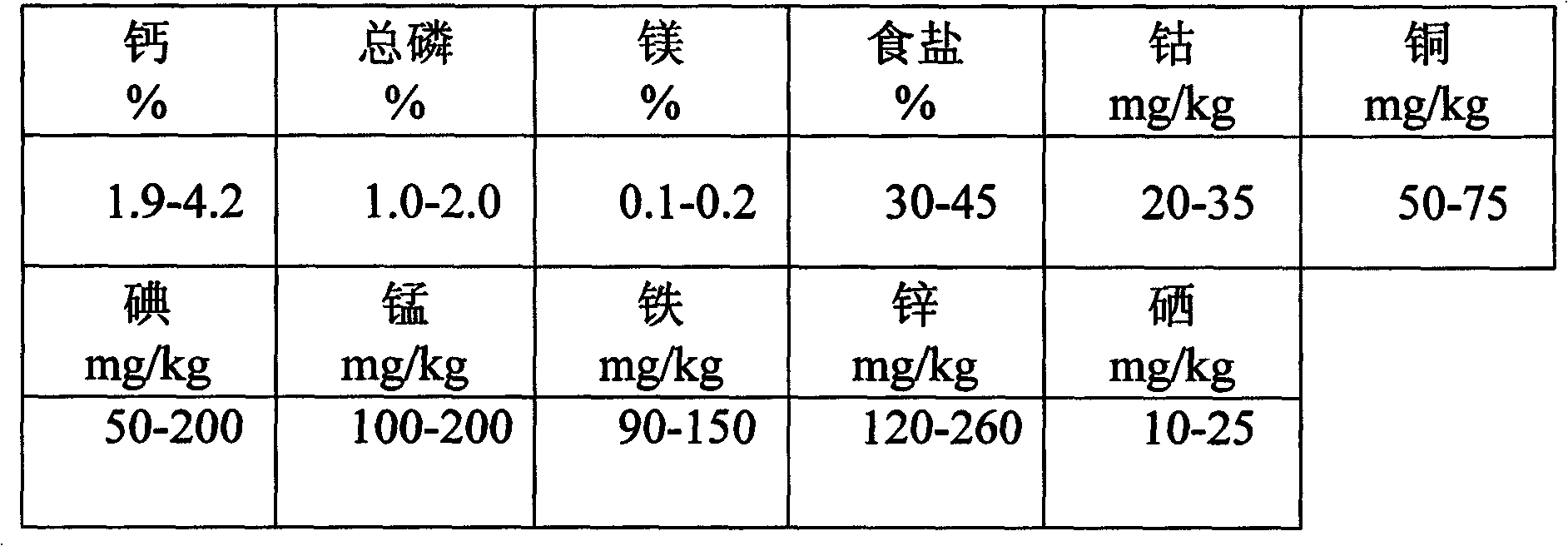

The invention relates to ruminant feed, in particular to ruminant beet pulp-urea particle feed. The invention aims to solve the problems of unbalanced nutrition and high production cost of the beet pulp particle feed prepared in the prior art. The particle feed disclosed by the invention comprises beet pulp, urea, maize flour, molasses, sodium sulfate, composite amino acid, zeolite, sodium dihydrogen phosphate, table salt, trace elements and a vitamin additive. The beet pulp-urea particle feed disclosed by the invention has the advantages that the nutrition is balanced, various amino acid are added in designed dosage, inorganic sulfur is added so that the nitrogen / sulphur proportion is balanced, the production performance of the ruminant is improved, and the morbidity of mastitis, dystocia, retained afterbirth and hair eating disease is reduced; and the cost is reduced, by introducing the molasses, the proportion of the beet pulp is improved, and the adding proportion of the maize flour is reduced so that the production cost is reduced by 40-50 percent. The beet pulp-urea particle feed prepared by the invention can be mainly fed to the ruminants, such as milk cow, beef cattle, mutton sheep, and the like.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Tan sheep fattening lamb special nutrition licking brick and preparation method thereof

InactiveCN101606641AChoose from a wide range of sourcesLow priceFood processingAnimal feeding stuffBrickSodium Bentonite

The invention relates to a Tan sheep fattening lamb special nutrition licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.10-0.15g of ferrous sulfate, 0.10-0.15g of zinc sulfate, 0.07-0.10g of copper sulfate, 0.12-0.16g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.15g of potassium iodide, 0.01-0.03g of cobalt chloride, 0.05-0.15g of magnesium oxide, 2-5g of chromium nicotinate, 30-150g of sodium sulfate, 50-100g of calcium hydrophosphate, 50-250g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite and 60-100g of molasses. The preparation method combines the chemical coagulation technology and the mechanical pressing technology, simultaneously targets the characteristics of Tan sheep fattening and develops the nutrition licking brick which supplements mineral nutrition for Tan sheep, thereby fully playing good properties of the Tan sheep. The licking brick is characterized by a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety, environmental protection and the like, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Method for making massive ginger brown sugar

InactiveCN104012828AEasy to eatEasy to operateNatural extract food ingredientsFood ingredient functionsSodium bicarbonateSingle crystal

The invention discloses a method for making massive ginger brown sugar, and relates to the field of edible sugar production. The method comprises the following preparation steps: putting crystal sugar syrup separated from monocrystalline and polycrystalline crystal sugar, and brown granulated sugar into a sugar dissolving pan; adding water to dissolve, filtering through a filter net and then conveying to a concentrating pan to carry out sugar boiling; removing excessive moisture to obtain molasses; controlling the pH value of the molasses by using citric acid and sodium bicarbonate, feeding the molasses into a sugaring car, simultaneously adding 5% of ginger powder and evenly stirring and sugaring the molasses by using an agitator; and putting on a sugar cloth of a work bench, and then marking off to obtain the massive ginger brown sugar. The method for making the massive ginger brown sugar disclosed by the invention is simple to operate and fewer in procedures, and the ginger brown sugar made by the method is convenient to eat, can be used for dispelling cold, and treating typhoid fever, headache and rhinobyon, and has good promotion and use value.

Owner:柳州市柳冰食品厂

Method for preparing silage by using bamboo shoot shells and silage pit

InactiveCN104522304APromote fermentationImprove palatabilityAgriculture tools and machinesAnimal feeding stuffBamboo shootsChemistry

The invention relates to the field of a silage method and aims at providing a method for preparing silage by using bamboo shoot shells and a silage pit. The method for preparing the silage by using the bamboo shoot shells comprises the following steps: collecting the fresh bamboo shoot shells and airing, mixing and uniformly stirring the bamboo shoot shells with table salt, urea, citric acid and molasses, placing the mixture into the silage pit to be sealed until an ensiling process is finished, and thus preparing the bamboo shoot shell mixture in the silage pit into the silage. The periphery of the silage pit is in a structure defined by cement walls and the vertical longitudinal section of the silage pit is trapezoid; lanes are arranged on one side of the top of the silage pit and one side of the bottom of the silage pit; and one side of the bottom of the silage pit is provided with a door capable of being nailed up by using a wood plate. The silage with good palatability and abundant nutrition, provided by the invention, can be directly used as a feed for ruminants in South China, so that grains are saved and guarantees are provided for sustainable development of a bamboo shoot processing industry.

Owner:ZHEJIANG FORESTRY UNIVERSITY

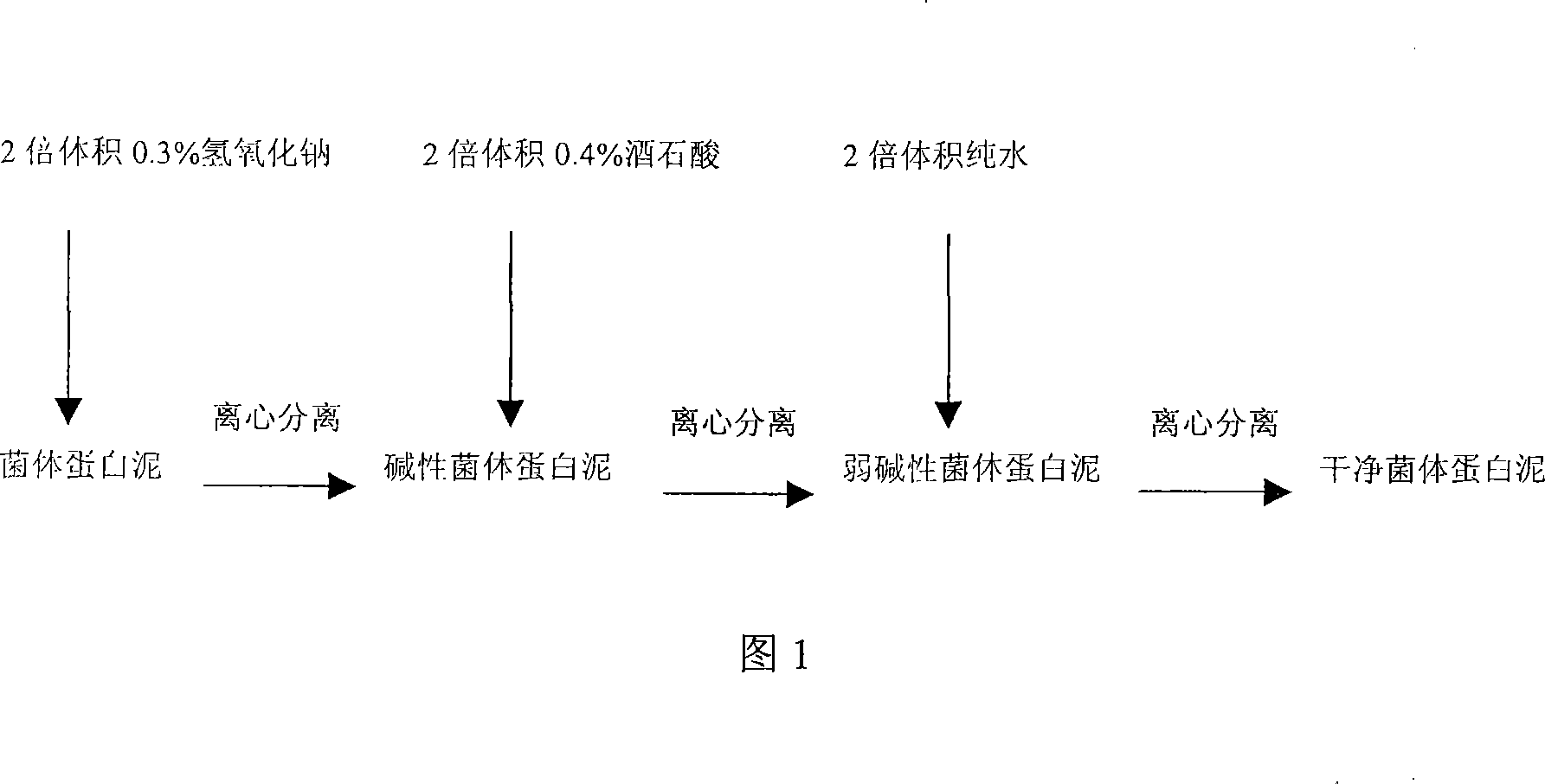

Method for producing single cell protein feed using waste molasses

InactiveCN101161094ALow priceStrong metabolismFood processingAnimal feeding stuffSynthesis methodsMagnesium salt

The present invention discloses a method for generating single cell albumen feedingstuff using waste gooey. To dilute the waste gooey until its chroma is 10 to 25 g / 100ml and back sagis is about 20 percent by adding water; then to adjust the pH value of the gooey to 4.0 to 6.0 by using rare hydrochloric acid, and placing for 12 hours so as to fetch upper clear liquid; adding nitrogen source with 0.00 to 10g / 100ml, phosphate with 0.5 to 1.5g / 100ml and magnesium salt with 0.1 to 0.5g / 100ml separately; adding the gooey culture medium after destroying bacterium into a mixing bacterium seed composing of geotrichum mildew, tropical candida and prion-producing candida, the weight ratio of the three bacteriums is 1:1:1, the access amount of the bacterium is 5 to 20 percent, under the condition of good oxygen, to bring with 44 to 72 hours at the temperature of 25 to 35 DEG C, then to separate the microzyme body, after cleaning the bacteriums to dry at the temperature of 105 DEG C to obtain single cell albumen feedingstuff. The present invention has low cost, composing method is simple, bacterium metabolizing is bloom, producing ratio is high, and it is not abstrained by area as well as climate condition.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Cattle and sheep fattening sustained-release protein licking brick and preparation method thereof

InactiveCN101606642AIncrease proteinEasy to useFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep fattening sustained-release protein licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.21-0.35g of ferrous sulfate, 0.21-0.35g of zinc sulfate, 0.14-0.21g of copper sulfate, 0.24-0.35g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.07-0.35g of potassium iodide, 0.03-0.07g of cobalt chloride, 1.14-3.35g of magnesium oxide, 35-160g of sodium sulfate, 50-100g of calcium hydrophosphate, 130-310g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite, 30-60g of molasses, 50-100g of extruded urea and 3-7g of acetoxy oxolinic acid. The preparation method combines the chemical coagulation technology and the mechanical pressing technology and simultaneously grants the extruded urea, the acetoxy oxolinic acid and other substances in the formula raw materials, so that the licking brick has the advantages of a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety and environmental protection, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

Mixed feed for mixotrophic culture of litopenaeus vannamei and sparus latus and preparation method thereof

ActiveCN103478438AMeet all needsImprove effective utilizationAnimal feeding stuffBiotechnologyMonocalcium phosphate

The invention discloses a mixed feed for mixotrophic culture of litopenaeus vannamei and sparus latus and a preparation method thereof, and the mixed feed comprises the following components: by weight, 10-20 parts of fishmeal, 1-10 parts of meat and bone meal, 1-5 parts of chicken powder, 1-5 parts of spray blood meal, 15-25 parts of soybean meal, 5-15 parts of peanut bran, 5-10 parts of concentrate soybean protein powder, 1-5 parts of cottonseed meal, 5-10 parts of corn protein powder, 1-5 parts of wheat middling, 1-3 parts of molasses yeast, 1-5 parts of DDGS (distillers dried grains with soluble), 1-3 parts of squid visceral meal, 1-3 parts of shrimp shell powder, 15-25 parts of high gluten flour, 1-3 parts of sea fish oil, 1-3 parts of soybean lecithin, 0.1-1 part of calcium dihydrogen phosphate, 0.1-0.5 part of choline chloride, 0.05-0.2 part of vitamin C-phosphate ester (35%), 0.1-0.3 part of bacillus subtilis, 0.1-0.3 part of mannan, 0.1-0.5 part of composite multivitamin and 0.5-1 part of composite mineral salts. The mixed feed is comprehensive in nutrients, high in feed utilization rate and low in cost.

Owner:JIANGMEN YUEHAI FEED

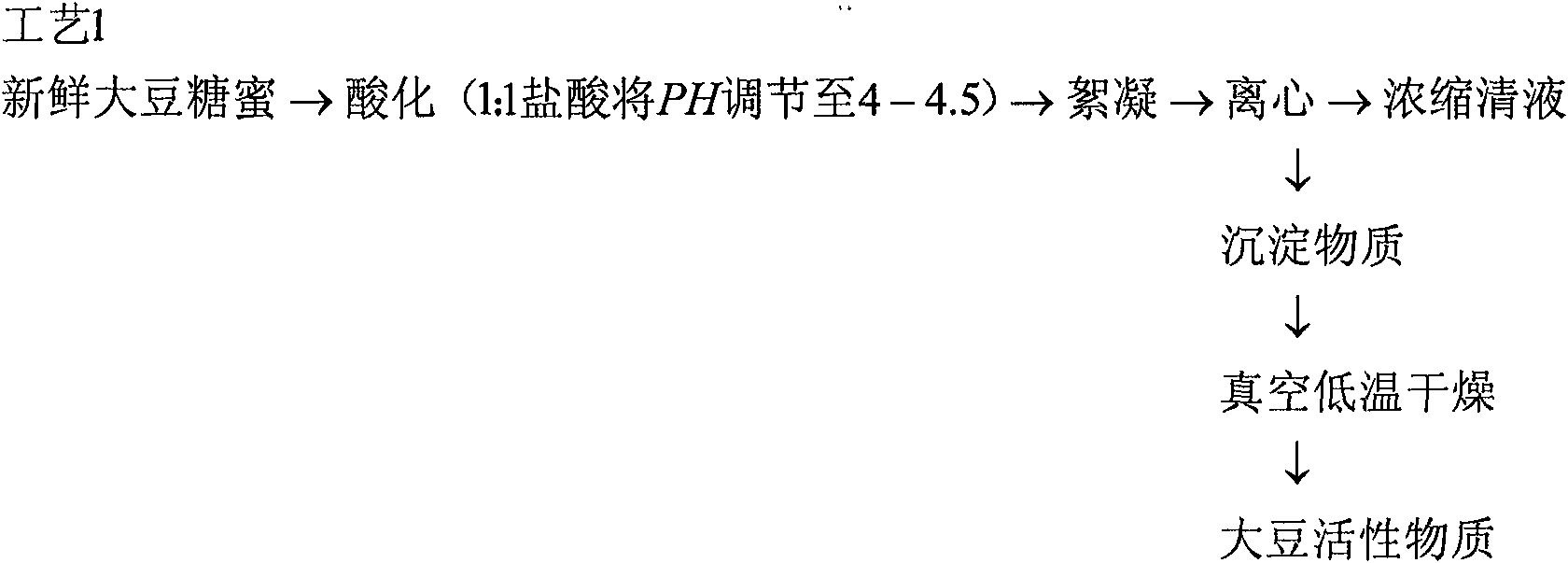

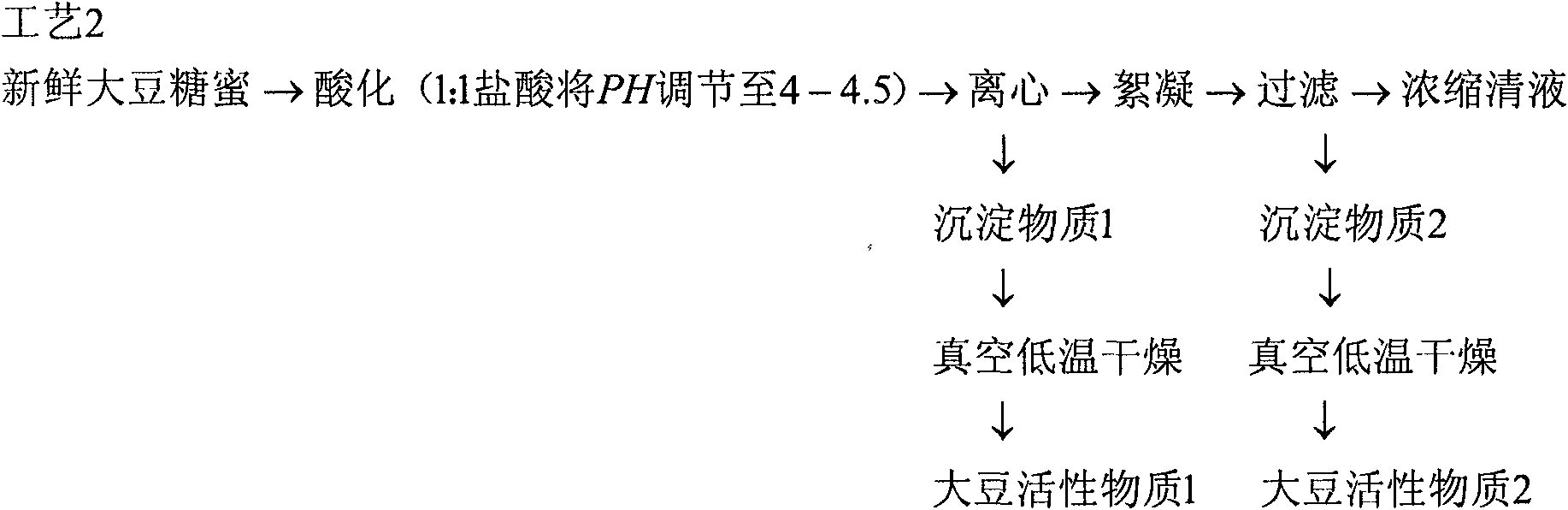

Soy phytochemical composition

Disclosed is a soy phytochemical composition obtained by removing soluble components out of acidified soy molasses by settling, decantation and / or centrifugation to obtain a precipitated residue sediment containing not less than 6% of isoflavones, not less than 18% of saponins and not less than 13% of crude low molecular weight protein material on a dry matter basis.

Owner:CHAJUSS DANIEL

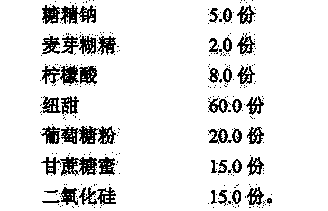

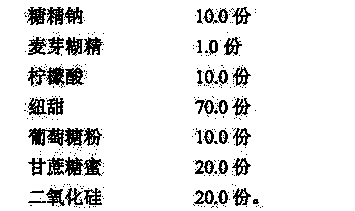

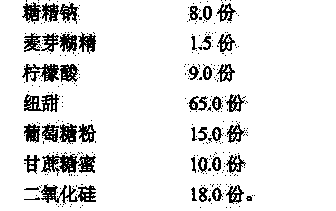

Composite sweetening agent for feed and preparation method thereof

InactiveCN104161190AAchieving Molecular State FusionIncrease feed intakeAnimal feeding stuffAccessory food factorsSugar caneProcessing cost

The present invention discloses a composite sweetening agent for feed and a preparation method thereof. The composite sweetening agent for feed comprises the following raw materials by weight: 5.0-10.0 parts of saccharin sodium, 1.0-2.0 parts of maltodextrin, 8.0-10.0 parts of citric acid, 60.0-70.0 parts of neotame, 10.0-20.0 parts of glucose powder, 10.0-20.0 parts of sugar cane molasses and 15.0-20.0 parts of silicon dioxide. The preparation method is as follows: dissolving the neotame, the saccharin sodium, the citric acid and the maltodextrin in a molasses solution, after completely dissolving, spraying the solution into the silicon dioxide in a whirlpool pelleter, absorbing while spraying, drying until the water content is less than 8.0%, performing ultrafine grinding, and uniformly mixing the powder with the glucose powder. According to the present invention, all the components of the composite sweetening agent for feed are preliminarily fully dissolved in the solution, and the true molecular state fusion makes the components of the sweetening agent can be uniformly felt by animals, thereby increasing the feed intake and the production performance of the animals. The composite sweetening agent for feed has characteristics of high saccharinity, low processing cost, good stability and reduced cost of formulated feed.

Owner:SHANGHAI XINNONG FEED

Cattle and sheep ultrafine particle feed licking brick and preparation method thereof

InactiveCN101606643AIncrease the areaImprove adsorption capacityFood processingAnimal feeding stuffSodium BentoniteBrick

The invention relates to a cattle and sheep ultrafine particle feed licking brick and a preparation method thereof, and the licking brick is characterized in that each kg of the licking brick comprises the following raw materials: 0.10-0.15g of ferrous sulfate, 0.10-0.15g of zinc sulfate, 0.07-0.10g of copper sulfate, 0.12-0.16g of manganese sulfate, 0.01-0.02g of sodium selenite, 0.05-0.15g of potassium iodide, 0.01-0.03g of cobalt chloride, 0.05-0.15g of magnesium oxide, 2-5g of chromium nicotinate, 30-150g of sodium sulfate, 50-100g of calcium hydrophosphate, 50-250g of extruded corn seed powder, 200-300g of common salt, 200-300g of bentonite and 60-100g of molasses. The substances adopt ultrafine smashing. The preparation method combines the chemical coagulation technology and the mechanical pressing technology and simultaneously carries out the ultrafine smashing treatment on the formula raw materials, so that the licking brick has the advantages of a wide range of sources for selecting a curing agent, low cost, more comprehensive nutrition, greater density, reasonable feed intake, sustained release of elements, health care, safety and environmental protection, thereby being suitable for raising levels with different feeding methods.

Owner:NINGXIA ACAD OF AGRI & FORESTRY SCI RES INST OF ANIM

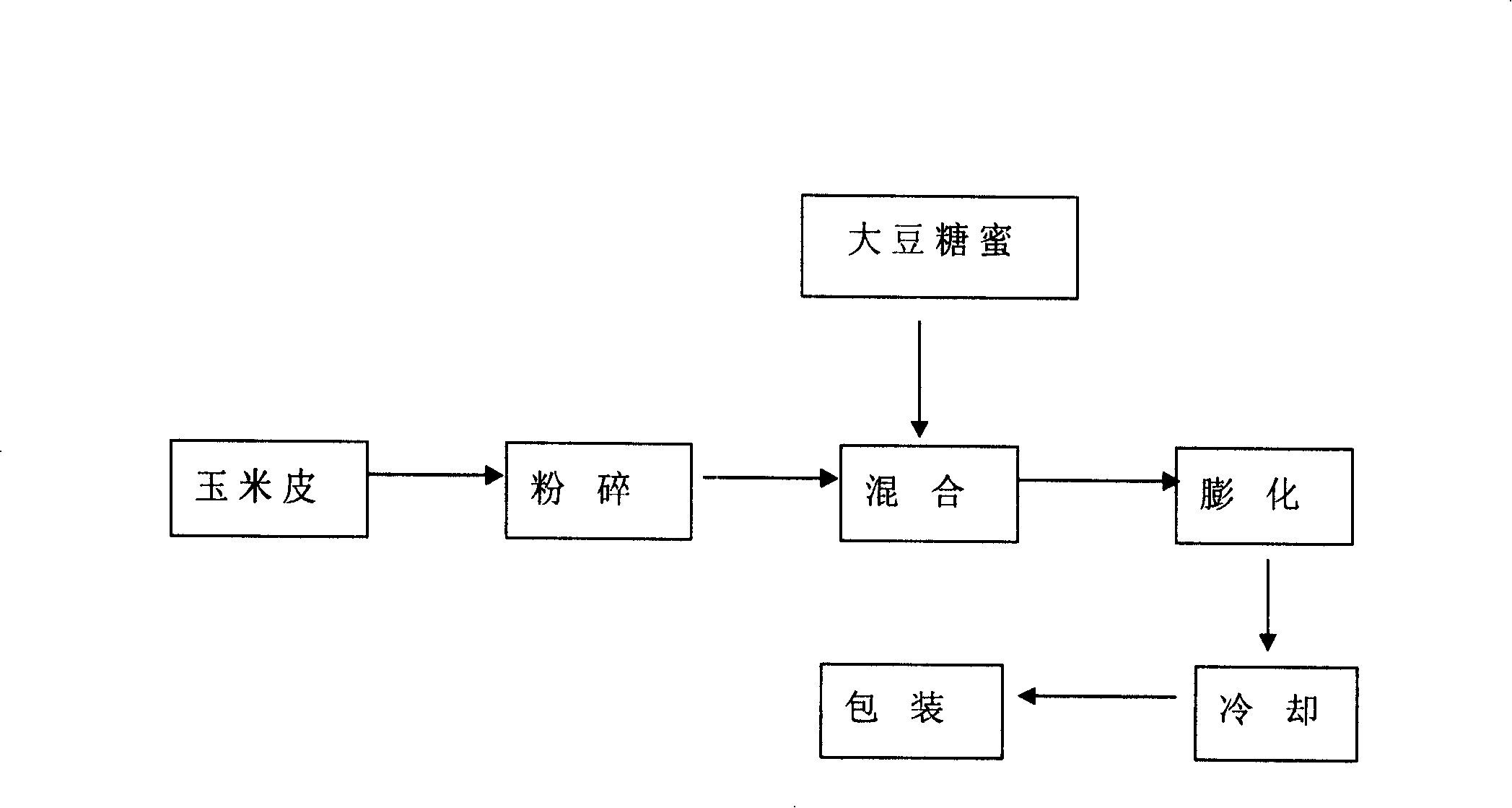

Process for manufacturing saccharified fibre feedstuff

InactiveCN101218958AImprove digestion and absorption rateImprove nutritional functionMetabolism disorderFood processingFiberWhey protein

The invention relates to a method for manufacturing a saccharified fiber feed, which is realized through the process steps of grinding, mixing, expansion, cooling, packaging, etc. The raw material component and mixture ratio of the invention is 6 to 8 portions of corn bran and 2 to 4 portions of soybean molasses or beet molasses. By changing a molecular reticular structure of the corn fiber to enhance the digestibility of the animals after expanding the corn fiber, the invention enhances the food calling effect by adding the soybean molasses. As the soybean molasses contain the nutrient substances such as oligosaccharide, soybean whey protein, isoflavone, saponin, etc., the nutrient function of the fiber products is strengthened, and the invention serves as an ideal fiber feed to replace wheat bran.

Owner:石晓岭

Method for producing pig feed from sisal dregs

The invention provides a method for producing a pig feed from sisal dregs. The pig feed is prepared from the following raw materials: sisal dregs, a fine feed, sugar cane molasses, corn flour, a gelsmium elegans solution and composite bacteria, wherein the composite bacteria is composed of lactic acid bacteria and saccharomycetes in a weight ratio of 1:1; the fine feed is wheat bran or peanut bran. The method comprises the following production steps: adding water into the sisal dregs produced by extrusion in a source mill according to a weight ratio of 1:1, adding the composite bacteria, adding the fine feed and the corn flour at the same time to perform combined fermentation, putting the mixture in a fermentation chamber the temperature in which is 30-50 DEG C, fermenting for 4-8 days to obtain a fermented feed, adding the sugar cane molasses and the gelsmium elegans solution into the fermented feed according to parts by weight, and mixing uniformly to obtain the finished pig feed. The pig feed produced from the sisal dregs is good in color and luster, rich in nutrition, fragrant in smell and good in taste, and is very suitable for feeding pigs.

Owner:莫明鑫

Debittered soybean sirup and preparation method and application thereof

InactiveCN101627815AThe preparation method is simple and efficientKeep active ingredientsFood preparationFlocculationSolid matter

The invention discloses a method for preparing a debittered soybean sirup, which comprises the following steps: performing acid deposition by adding an acid for mixing so that the pH is between 3.5 and 5.0, preferably between 3.8 and 4.3; performing flocculation by adding a flocculating agent; and performing separation by separating solid matters and the liquid part, and connecting the solid matters and the liquid respectively, wherein the liquid part is the debittered soybean sirup. The invention also discloses the debittered soybean sirup prepared by the method and application thereof.

Owner:秦皇岛金海食品工业有限公司

Immersion liquid for strawberry seed germination

InactiveCN106106570APlay an insecticidal and bactericidal effectAvoid mold and rotPlant growth regulatorsBiocideFragariaSesamum orientale

The invention discloses an immersion liquid for strawberry seed germination, and relates to the technical field of agricultural planting. The immersion liquid is made from the following raw materials by weight: 15-20 parts of black false hellebore, 10-15 parts of cactus, 10-15 parts of peanut cake, 8-13 parts of grape seed, 6-11 parts of sodium bentonite, 6-11 parts of tobacco straw ash, 5-10 parts of polyethylene glycol, 5-10 parts of coconut oil, 5-10 parts of urea, 4-8 parts of a yeast extract, 4-8 parts of black sesame powder, 3-6 parts of mineral powder, 2-4 parts of bamboo vinegar, 2-4 parts of sodium chloride, 1-2 parts of gibberellin, 1-2 parts of cane molasses and 500-600 parts of water. The immersion liquid is rich in nutrients promoting seed germination, and can play a insecticidal and bactericidal action to the seeds, and prevent the seeds from becoming moldy and decayed, thereby improving the germination rate and the survival rate of the seedlings.

Owner:固镇玉鹏生态农业文化园有限公司

Solid molasses products from liquid molasses

InactiveUS20080113072A1Reduce processing costsMore heat energySugar productsFood preparationChemical treatmentCalcium hydroxide

A novel processing method of producing a solid molasses product by a practical chemical processing method is provided. Liquid molasses is heated, mixed with calcium hydroxide at 2 to 25 percents (wt / wt) on a solid basis, dried to less than 15% moisture, and cooled to below 50 degree C. to convert the liquid molasses into the solid molasses in dry form. The solid molasses product is in block, particle or powder form. The oils with free fatty acid levels 20-80% (wt / vt) on a fat basis is added into liquid molasses and processed into molasses-fat block product with more hydrophobic function and water resistance. The process in this invention increases molasses content in the dried solid molasses from such as 42% to 90% and does not need dryer equipment, which increases the product value and reduces the related equipment and energy costs. The solid product in particle or powder form is free-flowing and easy to be handled, processed and delivered.

Owner:LEE JOHN H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com