Process for manufacturing saccharified fibre feedstuff

A manufacturing method and feed technology, applied in the field of feed manufacturing, can solve the problems of difficult digestion and absorption of animals, false estrus of sows, and low nutrient content, and achieve the goals of reducing the incidence of livestock and poultry, stabilizing product quality, and facilitating digestion and absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

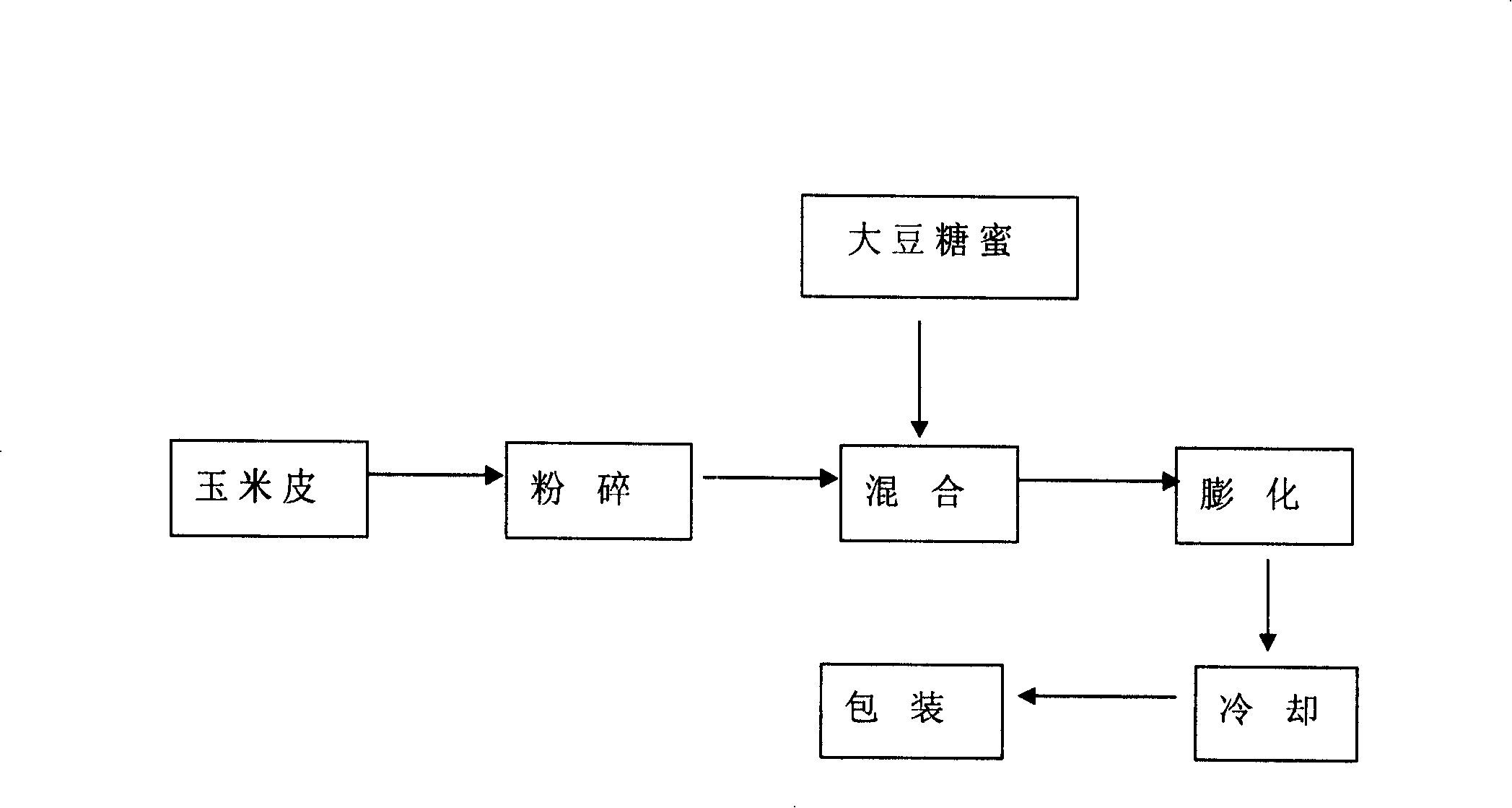

Image

Examples

Embodiment 1

[0027] 1. After pulverizing corn husks (starch factory waste), weigh 300 kg for later use.

[0028] 2. Weigh soybean molasses (moisture content 30-40%) into 200 kg for later use.

[0029] 3. Mix 300 kg of corn husks and 200 kg of soybean molasses, and the weight after mixing is 500 kg.

[0030] 4. Send 500 kg of mixed materials into Zhengchang 3200b extruder for extruding. The feeding frequency conversion speed is gradually adjusted from 700 to 1000 mir, and the temperature is gradually raised from normal temperature, and finally controlled between 100-140 ℃.

[0031] 5. Send the puffed material into the drum cooler for cooling, and the temperature after cooling is lower than 30°C.

[0032] 6. Quantitatively pack the cooled material, 40kg per bag, and then send it to the finished product warehouse.

Embodiment 2

[0034] 1. After crushing the corn husk, weigh 400 kg for later use.

[0035] 2. Weigh soybean molasses (moisture content 30-40%) into 100 kg for later use.

[0036] 3. Mix 400 kilograms of corn husks and 100 kilograms of soybean molasses, and the weight after mixing is 500kg.

[0037] 4. Send 500 kg of mixed materials into Zhengchang 3200b extruder for extruding. The feeding frequency conversion speed is gradually adjusted from 700 to 1000 mir, and the temperature is gradually raised from normal temperature, and finally controlled between 100-140 °C.

[0038] 5. Send the puffed material into the drum cooler for cooling, and the temperature after cooling is lower than 30°C.

[0039] 6. Quantitatively pack the cooled material, 40kg per bag, and then send it to the finished product warehouse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com