Composite sweetening agent for feed and preparation method thereof

A compound sweetener and feed technology, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of high use cost of feed compound sweetener, high production cost of ultrafine grinding, high stability and high use cost , to achieve the effect of increasing animal feed intake, expanding animal production performance, and reducing breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

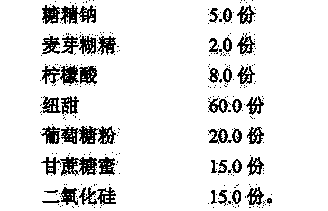

[0025] 1. Formula

[0026]

[0027] All the above-mentioned raw materials can be purchased in the raw material market.

[0028] Second, the operation process steps are as follows:

[0029] (1) Dissolution of components:

[0030] Dissolve neotame, sodium saccharin, citric acid, and maltodextrin in the molasses liquid according to the mass ratio, and fully dissolve;

[0031] (2) Spray into adsorption and dry:

[0032] Put the silicon dioxide according to the above mass ratio into the cyclone granulator, spray the dissolved liquid, spray, absorb, and dry until the spraying is completed, the drying inlet temperature is 80°C, and dry until the moisture is less than 8.0%;

[0033] (3) Superfine grinding:

[0034] Superfinely pulverize the dried material to below 200 mesh;

[0035] (4) Mixed packaging:

[0036] By the glucose powder of described mass proportion and the superfine pulverization material that last step obtains mixes, obtain compound feed sweetener finished pro...

Embodiment 2

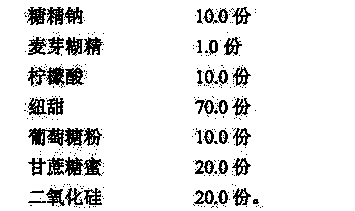

[0040] 1. Formula

[0041]

[0042] All the above-mentioned raw materials can be purchased in the raw material market.

[0043] Second, the operation process steps are as follows:

[0044] (1) Dissolution of components:

[0045] Dissolve neotame, sodium saccharin, citric acid, and maltodextrin in the molasses liquid according to the mass ratio, and fully dissolve;

[0046] (2) Spray into adsorption and dry:

[0047] Put the silicon dioxide according to the above mass ratio into the cyclone granulator, spray the dissolved liquid, spray, absorb, and dry until the spraying is completed. The drying inlet temperature is 85°C and dried until the water content is 8.0%;

[0048] (3) Superfine grinding:

[0049] Superfinely pulverize the dried material to below 200 mesh;

[0050] (4) Mixed packaging:

[0051] Mix the glucose powder according to the mass ratio and the superfine pulverized material obtained in the previous step evenly, measure and pack to obtain the finished co...

Embodiment 3

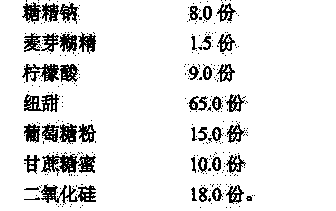

[0055] 1. Formula

[0056]

[0057] All the above-mentioned raw materials can be purchased in the raw material market.

[0058] Second, the operation process steps are as follows:

[0059] (1) Dissolution of components:

[0060] Dissolve neotame, sodium saccharin, citric acid, and maltodextrin in the molasses liquid according to the mass ratio, and fully dissolve;

[0061] (2) Spray into adsorption and dry:

[0062] Put the silicon dioxide according to the above mass ratio into the cyclone granulator, spray the dissolved liquid, spray, absorb, and dry until the spray is finished. 8.0%;

[0063] (3) Superfine grinding:

[0064] Superfinely pulverize the dried material to below 200 mesh;

[0065] (4) Mixed packaging:

[0066] Mix the glucose powder according to the mass ratio and the superfine pulverized material obtained in the previous step evenly, measure and pack to obtain the finished compound feed sweetener.

[0067] 3. Product composition testing:

[0068] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com