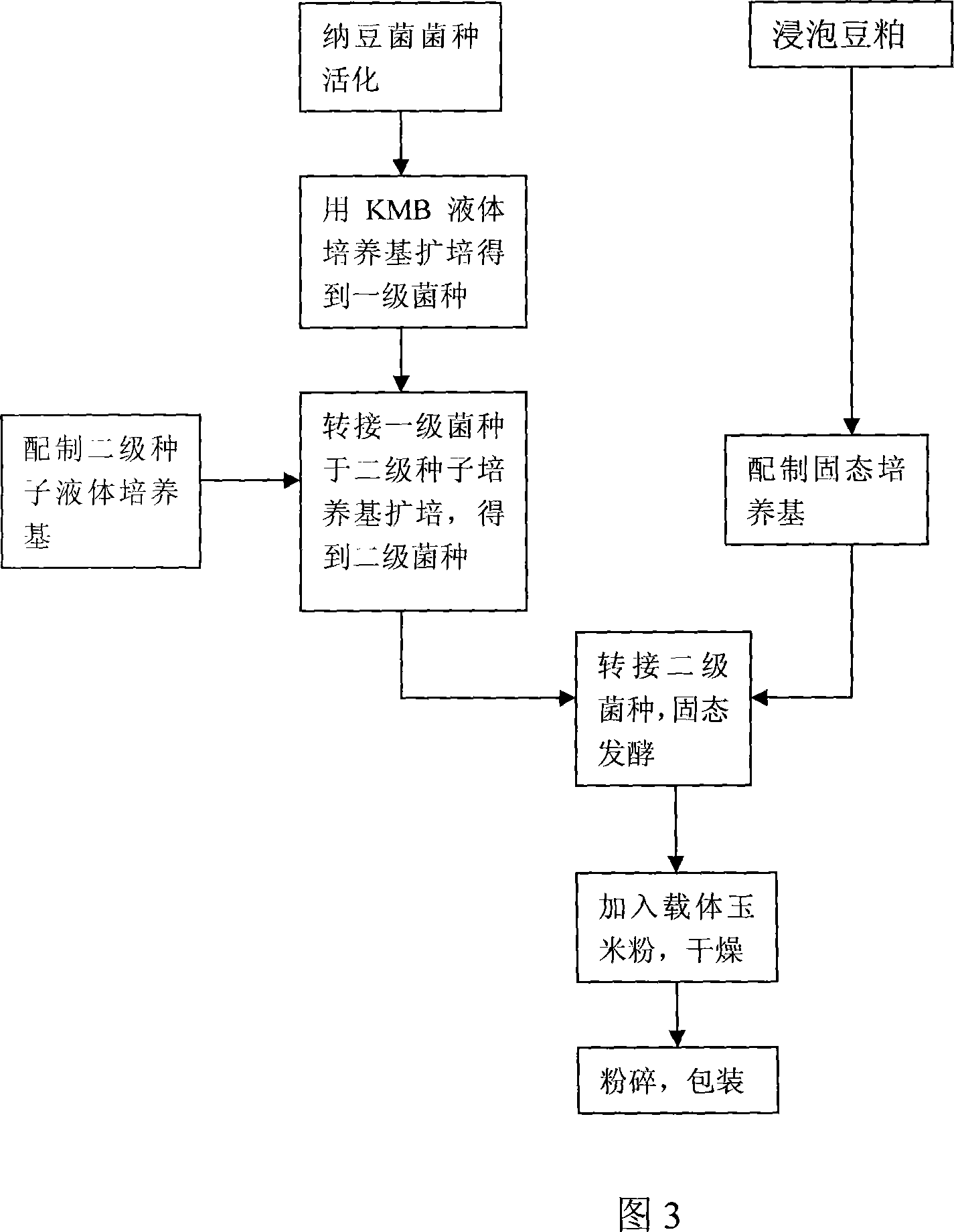

Solid fermentation process for producing natto bacillus feed additive with bean dregs

A technology of Bacillus natto and feed additives, which is applied in the field of solid-state fermentation, can solve problems that have not yet been seen, and achieve the effect of stable quality of live bacteria and rapid reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) The strains of Bacillus natto slant preservation or glycerol freezing preservation were used in KMB medium (KMB medium formula: NaCl8.0g, NaCl8.0g, NaCl 2 HPO 4 12H 2 O2.9g, K 2 HPO 4 0.2g, adjust the pH value to 7.0-7.5, add H 2 0 to 1000ml, 140 DEG C of autoclaving for 2-30 min), 37 DEG C, 250 rpm shaking flask culture for 13 hours, obtain the first-grade strain liquid;

[0034] 2) Dissolve 3% soybean meal, 1% cornstarch, 1% corn steep liquor and 0.2% NaCl in an aqueous solution with a particle size of 80 mesh and 3% by weight. Filter through double-layer gauze, adjust the pH value to 6.5, add water, sterilize under high pressure at 121°C for 15 minutes, add 2% of the above-mentioned primary strain liquid, and incubate at 37°C for 12 hours to obtain the secondary strain liquid;

[0035] 3) Soak the soybean meal in water with a pH value of 5.5 for 1 hour. The water content of the swelled soybean meal is 55%, and then add 0.3% by weight of NaCl, 3% of carbon sou...

Embodiment 2

[0040] 1) Bacillus natto slant-preserved or glycerin-frozen strains were cultured in shake flasks with KMB medium, and cultured in shake flasks at 37° C. and 250 rpm for 12 hours to obtain a first-grade strain liquid;

[0041] 2) Dissolving 5% soybean meal powder, 2% cornstarch, 1.5% corn steep liquor, and 0.5% NaCl in an aqueous solution with a particle size of 80 meshes by weight, filtering through double-layer gauze, adjusting the pH value to 7.0, and replenishing water. Autoclave at 121°C for 15 minutes, add 4% of the above-mentioned primary strain solution, and incubate at 37°C for 14 hours to obtain the secondary strain liquid;

[0042] 3) Soak the soybean meal in water with a pH value of 8.5 for 2 hours, the water content of the expanded soybean meal is 70%, and then add 1.2% NaCl by weight, 5% carbon source sucrose, and 5% nitrogen source (NH4) 2 SO 4 , mix well, cook and sterilize, and cool to obtain a solid culture medium;

[0043] 4) Inoculate 7.5% of the above-me...

Embodiment 3

[0047] 1) Bacillus natto slant-preserved or glycerin-frozen strains were cultured in shake flasks with KMB medium, and cultured in shake flasks at 37° C. and 250 rpm for 14 hours to obtain a first-grade strain liquid;

[0048] 2) Dissolve 7% soybean meal powder, 3% cornstarch, 2% corn steep liquor, and 0.8% NaCl in an aqueous solution with a particle size of 80 mesh, filter through double-layer gauze, adjust the pH value to 7.0, and replenish water. Autoclave at 121°C for 15 minutes, add 6% of the above-mentioned primary strain solution, and incubate at 37°C for 16 hours to obtain the secondary strain liquid;

[0049] 3) Soak the soybean meal in water with a pH value of 7.0 for 1 hour, the water content of the swollen soybean meal is 60%, and then add 0.9% NaCl, 5% cornstarch, and 5% gelatin by weight, mix well, and cook to sterilize , cooled to obtain a solid medium;

[0050] 4) Inoculate 10% of the above-mentioned secondary strain liquid into the solid medium, mix well, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com