Method for preparing silage by using bamboo shoot shells and silage pit

A technology for silage and silage pits, applied in the field of silage, can solve problems not involved in the preparation of silage bamboo shoot shell feed and the design of silage pits, and achieve the effects of increased digestibility of rumen dry matter, low price, and improved nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

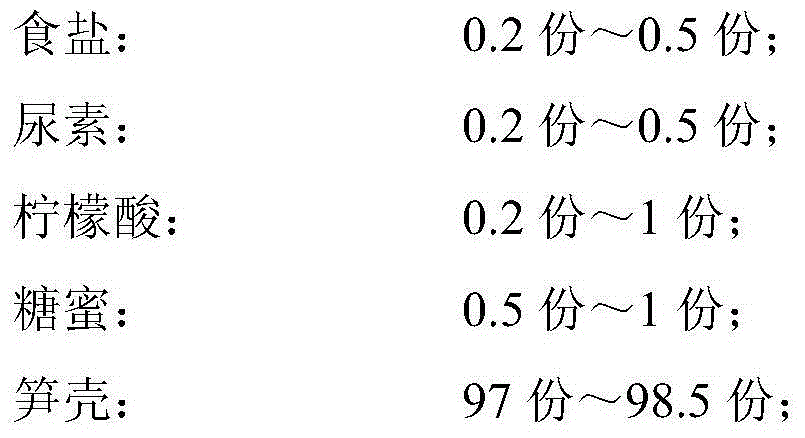

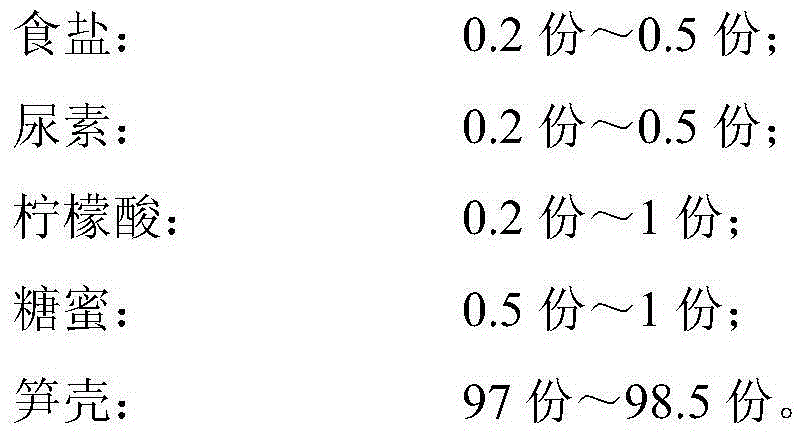

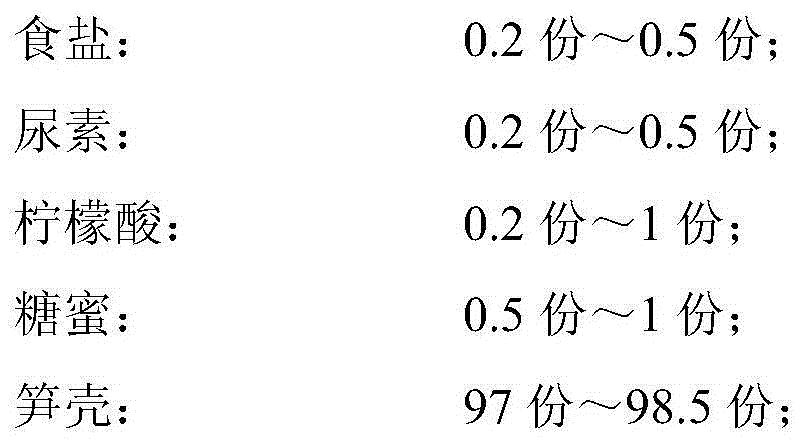

Embodiment 1

[0036] Get 0.5 part of table salt, 0.5 part of urea, 1 part of citric acid, 1 part of molasses (both parts by weight), be dissolved in 3 parts of water (parts by weight) and stir, evenly spray on 97 parts of bamboo shoot shells (bamboo shoots) with a high-pressure sprayer The weight water content of the shell is 60%), fill the well-mixed bamboo shoot shells in the green storage cellar as soon as possible (complete within 2 days), fully compact, the top is rounded after filling, and the surface is covered with two layers of polyethylene film , to ensure adequate sealing. After 15 days of silage, check the pH of the silage liquid flowing out from the crack of the wooden door at the bottom of the silo every day. When the pH drops below 4.0, it indicates that the silage is over.

Embodiment 2

[0038] Get 0.4 part of table salt, 0.4 part of urea, 0.2 part of citric acid, 0.8 part of molasses (both parts by weight), dissolve in 3 parts of water (parts by weight) and stir evenly, evenly spray on 98.2 parts of bamboo shoot shells (bamboo shoots) with a high-pressure sprayer The weight water content of the shell is 65%), fill the well-mixed bamboo shoot shells in the green storage cellar as soon as possible (complete within 2 days), fully compact, and the top is round after filling, and the surface is covered with two layers of polyethylene film , to ensure adequate sealing. After 15 days of silage, check the pH of the silage liquid flowing out from the wooden door crack at the bottom of the silo every day. When the pH drops below 4.0, it indicates that the silage is over.

Embodiment 3

[0040] Get 0.2 part of table salt, 0.2 part of urea, 0.6 part of citric acid, 0.5 part of molasses (both parts by weight), be dissolved in 3 parts of water (parts by weight) and stir evenly, evenly spray on 98.5 parts of bamboo shoot shells (bamboo shoots) with a high-pressure sprayer The shell weight water content is 70%), fill the mixed bamboo shoot shells in the green storage cellar as soon as possible (complete within 2 days), fully compact, the top is round after filling, and the surface is covered with two layers of polyethylene film , to ensure adequate sealing. After 15 days of silage, check the pH of the silage liquid flowing out from the wooden door crack at the bottom of the silo every day. When the pH drops below 4.0, it indicates that the silage is over.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com