Method for producing single cell protein feed using waste molasses

A single-cell protein and waste molasses technology, which is applied in the field of waste resource utilization to achieve the effects of vigorous bacterial metabolism, obvious economic benefits and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

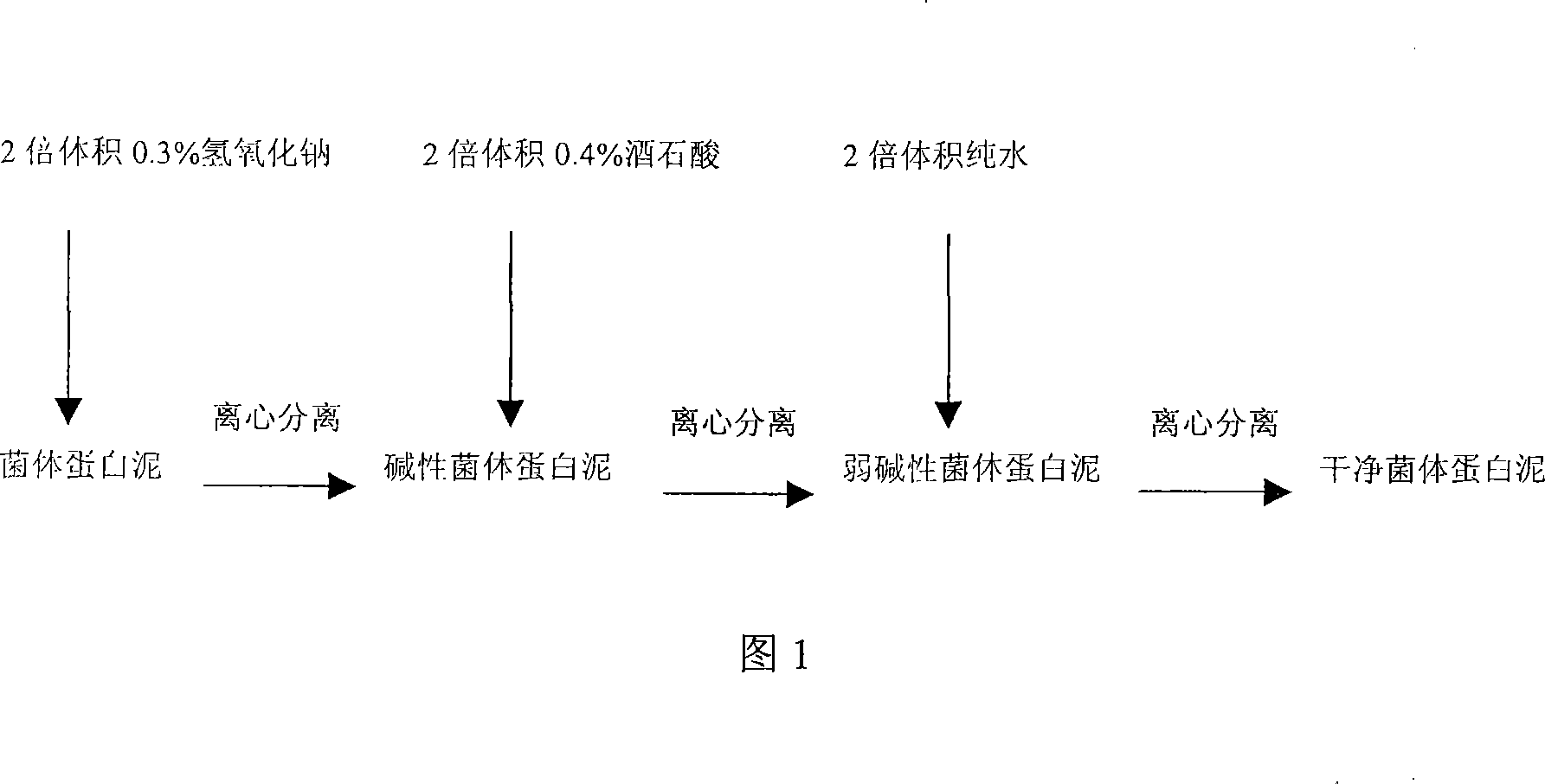

[0010] Dilute the waste molasses with water to a concentration of 20g / 100ml, and the sag after dilution reaches 20% (Brix: 20%); then adjust the pH of the waste molasses to 5 with dilute hydrochloric acid (hydrochloric acid and water are mixed in a volume ratio of 1:9) , let it stand for 12 hours, take the supernatant night; add yeast extract 3g / 100ml, magnesium sulfate 0.3g / 100ml, superphosphate 0.6g / 100ml, potassium dihydrogen phosphate 0.3g / 100ml, mix and sterilize evenly, and then throw in Geotrichum candidum The mixed bacteria composed of GIM2.69, Candida tropicalis GIM2.7 and Candida utilis GIM2.8, the weight percentage of the three kinds of bacteria is 1:1:1, and the insertion amount of bacteria is 10%. Under the condition of oxygen, the yeast was cultured in a constant temperature shaking incubator at 100r / min at 30°C for 72 hours, and then the yeast cells were centrifuged and washed (see Figure 1 for the cleaning method of the cells), and then the yeast cells were Dry...

Embodiment 2

[0012] Dilute the waste molasses with water to a concentration of 15g / 100ml, and the sag after dilution reaches 20% (Brix: 20%); then adjust the pH of the waste molasses to 4.5 with dilute hydrochloric acid (hydrochloric acid and water are mixed in a volume ratio of 1:9) , stand still for 12 hours, take the supernatant night; add urea 3g / 100ml, magnesium sulfate 0.2g / 100ml, superphosphate 0.3g / 100ml, potassium dihydrogen phosphate 0.2g / 100ml, mix and sterilize evenly, and then throw in Geotrichum candidum GIM2 .69, the mixed bacteria composed of Candida tropicalis GIM2.7 and Candida utilis GIM2.8, the weight percentage of the three kinds of bacteria is 1:1:1, the insertion amount of bacteria is 15%, in aerobic Under conditions, yeast culture was carried out in a constant temperature shaking incubator at 100r / min at 28°C for 60 hours, and then the yeast cells were centrifuged and washed (see Figure 1 for the cleaning method of the cells), and then the yeast cells were washed at ...

Embodiment 3

[0014] Dilute the waste molasses with water to a concentration of 20g / 100ml, and the sag after dilution reaches 20% (Brix: 20%); then adjust the pH of the waste molasses to 5.5 with dilute hydrochloric acid (hydrochloric acid and water are mixed in a volume ratio of 1:9) , let it stand for 12 hours, take the supernatant night; add sodium nitrate 3g / 100ml, magnesium sulfate 0.4g / 100ml, superphosphate 0.5g / 100ml, potassium dihydrogen phosphate 0.4g / 100ml, mix and sterilize evenly, and then throw in Geotrichum candidum The mixed bacteria composed of GIM2.69, Candida tropicalis GIM2.7 and Candida utilis GIM2.8, the weight percentage of the three kinds of bacteria is 1:1:1, and the insertion amount of bacteria is 18%. Under the condition of oxygen, the yeast was cultured in a constant temperature shaking incubator at 100r / min at 32°C for 50 hours, and then the yeast cells were centrifuged and washed (see Figure 1 for the cleaning method of the cells), and then the yeast cells were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com