Debittered soybean sirup and preparation method and application thereof

A technology for debittering soybean molasses, which is applied in the field of debittering soybean molasses and its preparation, and can solve the problems of insignificant debittering effect, high solvent residue and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

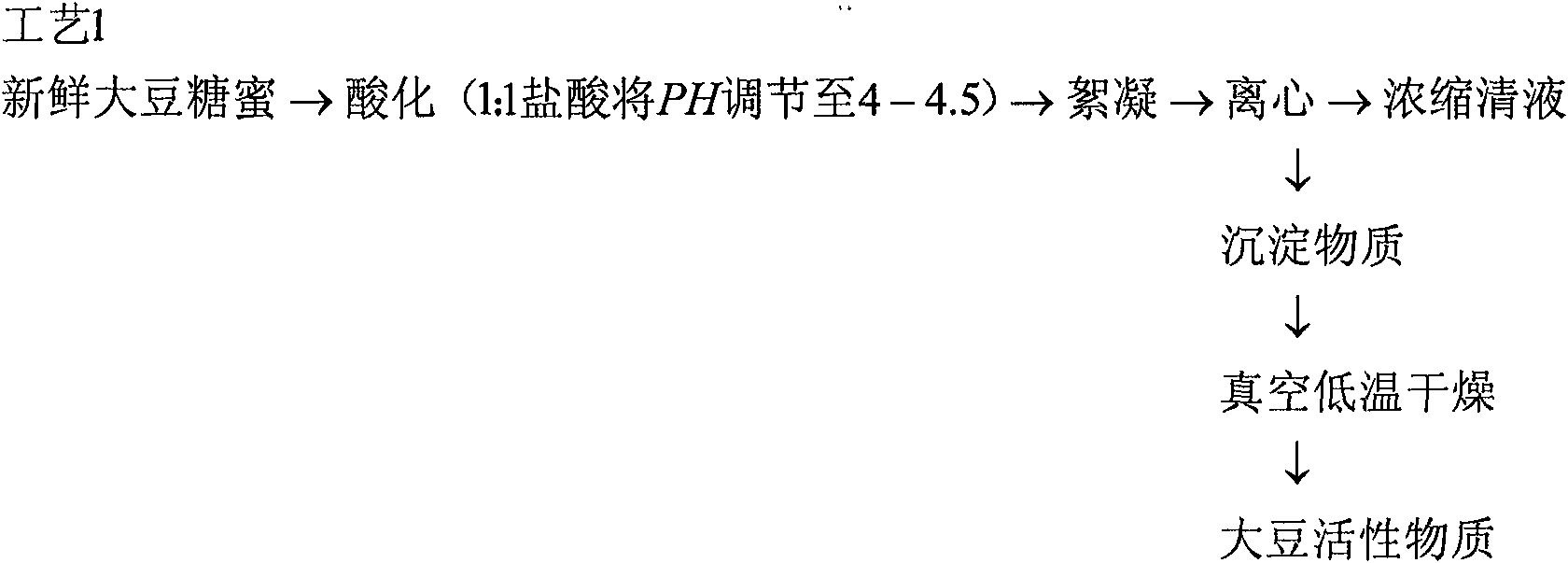

[0047] A preparation method for debittering soybean molasses, characterized in that said method comprises steps:

[0048] Acid precipitation: add acid and mix to make pH3.5-5.0; preferably pH3.8-4.3;

[0049] Flocculation: add flocculant to flocculate;

[0050] Separation: separating the solid matter and the liquid part formed by the acid precipitation and flocculation steps step by step or once, and collecting the solid matter and liquid respectively, and the liquid part is the soybean molasses after debittering.

[0051] Preferably, the preparation method of the debittered soybean molasses provided by the invention comprises the following steps:

[0052] (a) fresh soybean molasses and acid are mixed to make pH3.5-5.0; preferably pH3.8-4.3;

[0053] (b) Add chitosan solution, stir at less than 35°C, preferably 15-30°C; more preferably, settling at 15-25°C for more than 30 minutes, preferably settling for 30-60 minutes; more preferably 30-40 minutes; and

[0054](c) Centri...

Embodiment 1

[0086] Preparation of debittered soybean molasses I

[0087] Get 1000 milliliters of solid content 34.01%, fresh soybean dilute molasses (purchased from Qinhuangdao Jinhai Food Industry Co., Ltd.) with an acidity value of 5.7, adjust the pH to 4.0 with hydrochloric acid diluted with a volume ratio of 1: 1, and leave it to stand for 10 minutes under vigorous stirring Add the chitosan solution containing 0.8 gram of chitosan (alpha-chitosan, molecular weight is less than 50,000, deacylation degree is greater than 85%) solid chitosan solution, after 4000 rpm ( The centrifugal force is 3300×g) and centrifuged for 10 minutes (this centrifugal condition is the actual experimental condition, not the minimum requirement) to obtain three parts: the supernatant, the debittering supernatant and the solid precipitation, and the supernatant and the sediment are vacuum-dried for 2 hours below 70 degrees Celsius to obtain The content of soybean isoflavones is 2.86%, the content of crude prot...

Embodiment 2

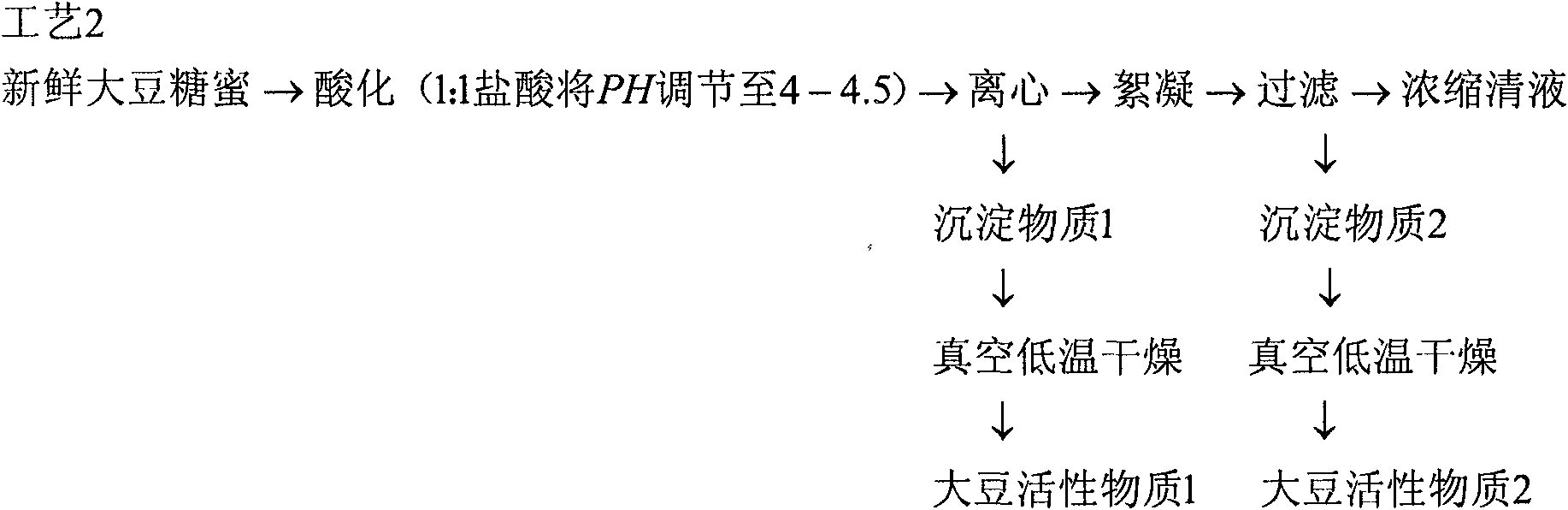

[0089] Preparation of Debittered Soy Molasses II

[0090] Get 1000 milliliters of fresh soybean molasses with a solid content of 39.53% and an acidity value of 5.5 (purchased from Qinhuangdao Jinhai Food Industry Co., Ltd.), adjust the pH to 4.0 with hydrochloric acid diluted with a volume ratio of 1: 1, and use 4000 rpm after standing for 10 minutes. (centrifugal force 3300×g) centrifuged for 10 minutes (this centrifugation condition is the actual experimental condition and not the minimum requirement) to obtain two parts, the supernatant and the precipitated substance, and vacuum-dried the precipitated substance 1 below 70 degrees Celsius to obtain a content of soybean isoflavones of 5.49%, crude 14.59% protein content, 13.82% total sugar content, 3.54% fiber content rich soybean active substance 1. Add chitosan solution equivalent to 0.8 g of chitosan solids to the supernatant part under vigorous stirring, flocculate at room temperature at 18 degrees Celsius for 40 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com