Fatty acid/modified fly ash composite phase change energy storage material and preparation method thereof

A technology of composite phase change and energy storage materials, which is applied in the field of fatty acid/modified fly ash composite phase change materials and its preparation, can solve the problems of reducing the service life of energy storage materials, low thermal conductivity of fatty acids, volume expansion, etc., and achieve The effect of prolonging the service life, good heat storage performance, and reducing the phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

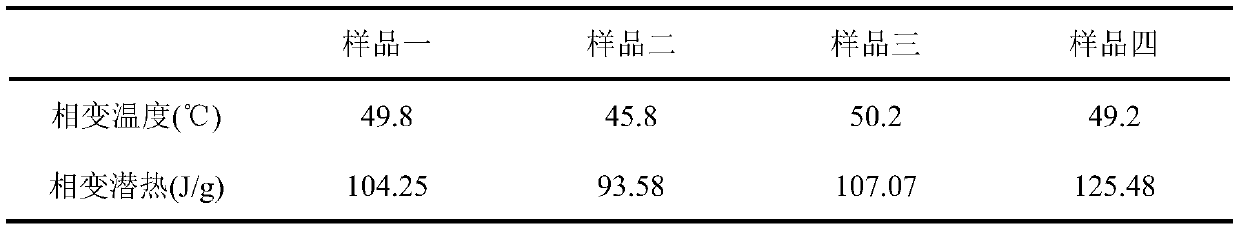

Embodiment 1

[0023] 1. Weigh 3.2g of myristic acid and 1.8g of palmitic acid respectively and place them in a reaction vessel, and heat the reaction vessel at 65°C to melt all the myristic acid and palmitic acid in the reaction vessel. Stirring was continued for 40 minutes at this temperature, and the rotation speed was 200 r / min, so that the fatty acids were fully mixed.

[0024] 2. Weigh 5.0 g of fly ash (25% of fly ash with a particle size of 5 μm, 20 μm, 30 μm, and 40 μm), and prepare 200 mL of citric acid solution of 0.75 mol / L with deionized water. Mix it with fly ash in a beaker, heat and stir in a constant temperature water bath at 50°C for 3 hours, filter it with suction, wash it with deionized water until the solution is neutral, and dry it in a constant temperature drying oven to constant weight to obtain the modification fly ash.

[0025] 3. Weigh 5.0 g of the myristic acid-palmitic acid binary eutectic mixture in step 1, melt it at a temperature of 60°C, add 5.0 g of the modi...

Embodiment 2

[0027] 1. Weigh 2.7g of myristic acid, 1.6g of palmitic acid, and 0.7g of stearic acid and place them in a reaction vessel, heat the reaction vessel in a water bath at 70°C to completely melt the fatty acids, turn on the magnetic stirring, and magnetic stirring The rotating speed is 200r / min, the temperature is 70°C, and the stirring time is 35min, so that the fatty acids are fully mixed.

[0028] 2. Same as 2 and 3 in Embodiment 1. The myristic acid-palmitic acid-stearic acid / modified fly ash composite phase change material is sample two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com