Bifunctional oxygen electrocatalyst and preparation and application thereof

A catalyst, bifunctional technology, applied in bifunctional oxygen electrocatalyst and its preparation and application fields, to achieve the effects of high capacity, easy scale and sustainable production, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

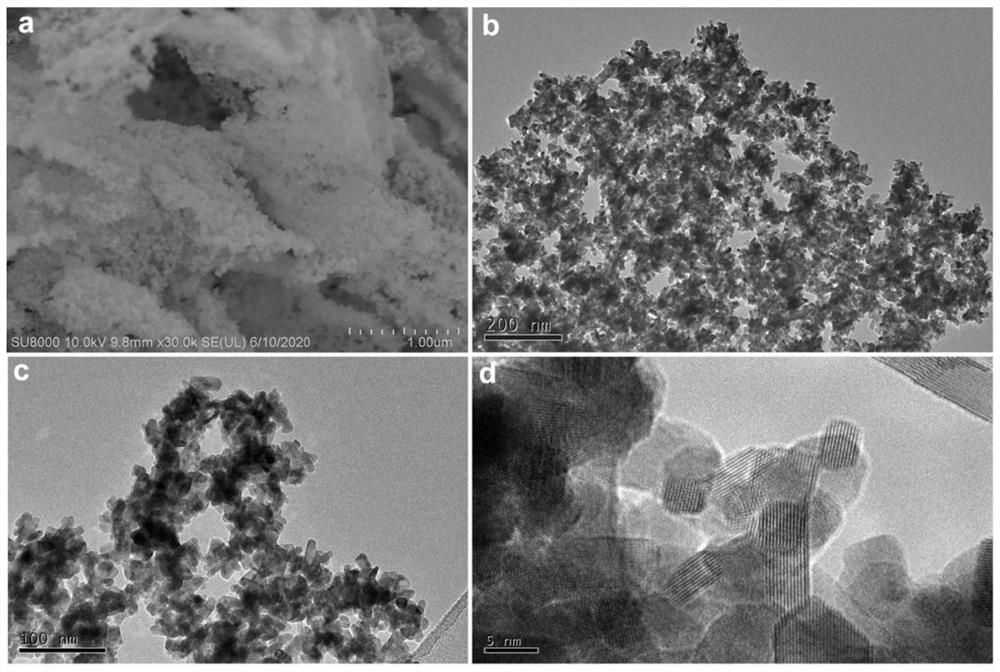

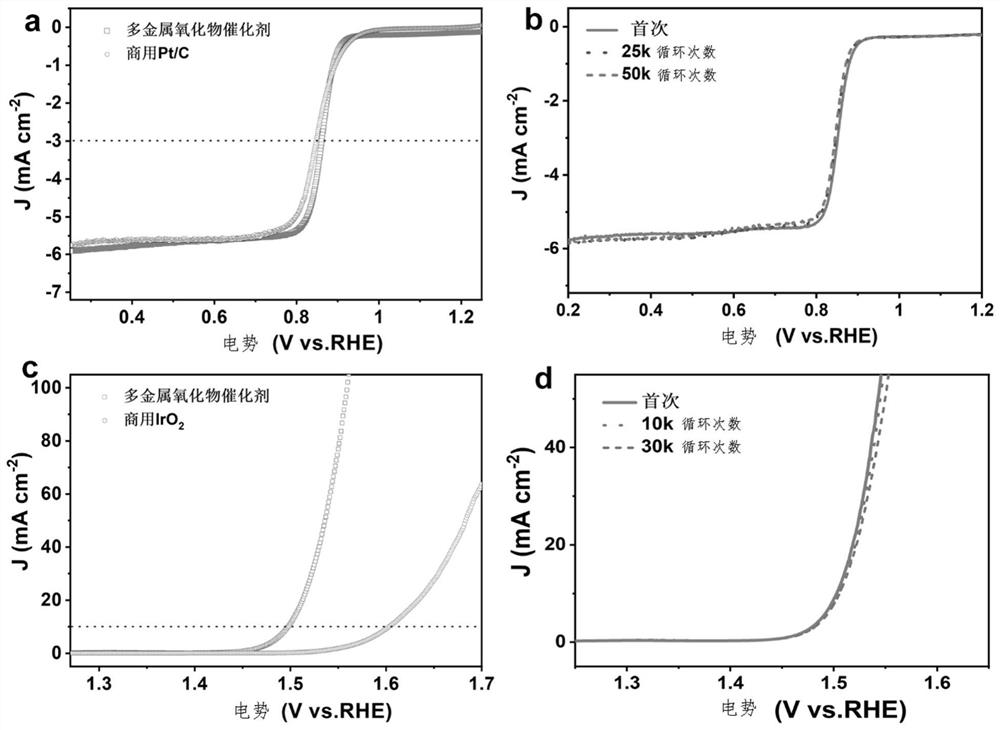

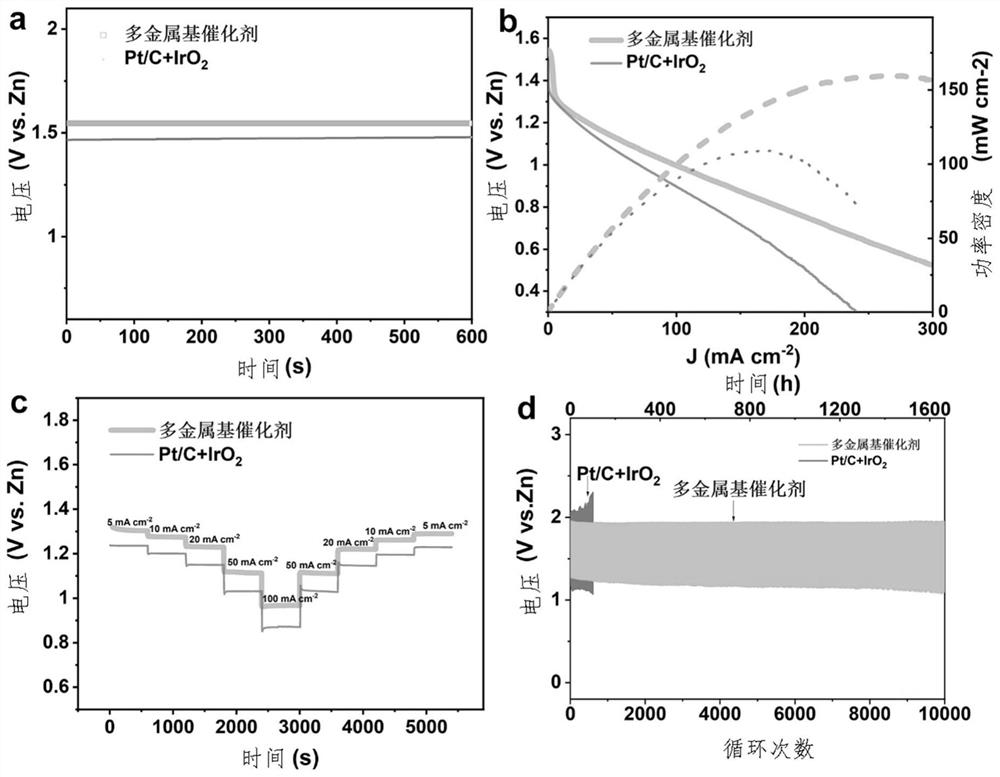

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned catalyst is also disclosed in the embodiment of the application, including the following steps:

[0042] 1) uniformly mixing the metal salt of the element A, the metal salt of the element B, and the metal salt of the element C with carbohydrates and gas-generating compounds in water to form a precursor solution;

[0043] 2) Pre-calcining the precursor solution; calcining the product obtained by the pre-calcining to obtain the catalyst.

[0044] Optionally, the preparation method of the catalyst consists of the above steps.

[0045] In the embodiment of the present application, the precursor solution is pre-fired in an oven to obtain a three-dimensional foam supported by a metal salt;

[0046] In the embodiment of the present application, the carbohydrate is selected from chitosan, sucrose, fructose, glucose, maltose, cellulose, starch, hemicellulose, mannose, fructan, xylitol, arabinose, erythrose Any one or more of sugar,...

Embodiment 1

[0058] (1) Weigh a certain amount of K 2 PtCl 6 and FeCl 3 Dissolve in deionized water so that the total concentration of metal salts is 0.1mol / L, where Pt 4+ and Fe 3+ The concentration is 0.05mol / L.

[0059] (2) Add chitosan and ammonium chloride subsequently, obtain a clear solution through continuous stirring, the concentration of chitosan is 1mol / L, and the concentration of ammonium chloride is 4mol / L.

[0060] (3) After that, the beaker was put into an oven and pre-fired at 160° C. for 10 h to obtain a three-dimensional metal salt-loaded chitosan foam.

[0061] (4) Finally, put the obtained foam into a muffle furnace, calcinate at 600°C for 12 hours under an argon atmosphere, wash and dry with deionized water to obtain a PtFe-based mixed catalyst Pt 0.5 Fe 0.5 o 2 .

Embodiment 2

[0063] (1) Weigh a certain amount of K 2 PtCl 6 and FeCl 3 Dissolve in deionized water so that the total concentration of metal salts is 0.01mol / L, where Pt 4+ and Fe 3+ The concentration is 0.005mol / L.

[0064] (2) Then add sucrose and ammonium sulfate, and continuously stir to obtain a clear solution, the concentration of sucrose is 0.1 mol / L, and the concentration of ammonium sulfate is 0.1 mol / L.

[0065] (3) Afterwards, the beaker was put into an oven and pre-fired at 120° C. for 2 hours to obtain a three-dimensional metal salt-loaded sucrose foam.

[0066] (4) Finally, put the obtained foam into a muffle furnace, calcinate at 350°C for 6h, wash and dry with deionized water to obtain a PtFe-based mixed oxide catalyst Pt 0.5 Fe 0.5 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com