Porous hydrogel microsphere and preparation method thereof

A technology of porous hydrogel and microspheres, applied in the field of biological materials, can solve the problems of impermeability of nutrients, poor biocompatibility of porous microspheres, complicated operation, etc. The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

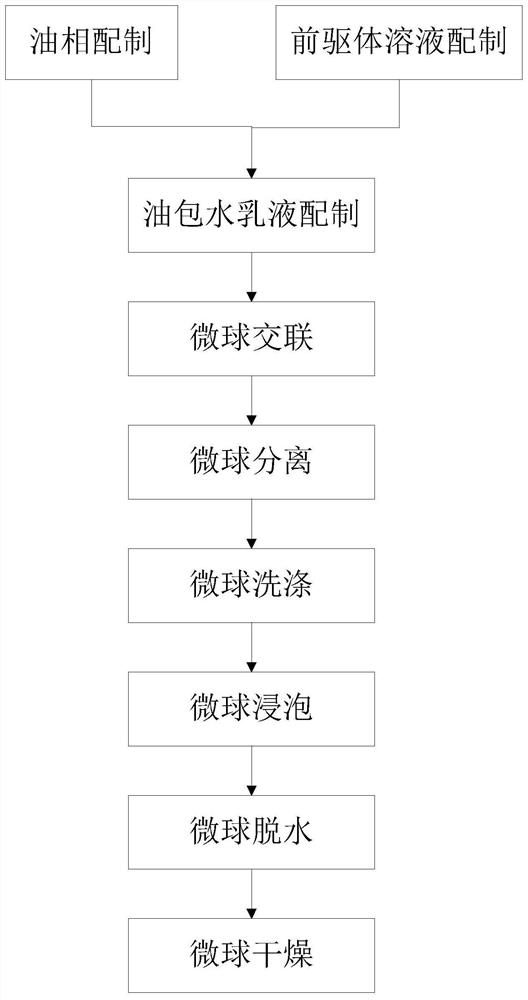

[0082] like figure 1 Shown:

[0083] 1) Add 0.1g of Span 80 to 100g of liquid paraffin (emulsifier: oily solvent = 0.1:100), stir and dissolve at 60°C to prepare the oil phase;

[0084] 2) Add 0.5g GelMA (5%), 0.025g initiator LAP (0.25%) and 0.1g PEO (1%) to 10mL deionized water, heat and stir in the dark at 50°C to obtain a hydrogel precursor solution;

[0085] 3) Add 1 mL of the precursor solution in the above step 2) to 20 mL of the oil phase prepared in step 1) and heat and stir at a speed of 500 r / min for 20 min to form a water-in-oil emulsion;

[0086] 4) The light intensity is 100mW / cm 2 A 405nm light source irradiates the above-mentioned water-in-oil emulsion for 30 minutes to cause a cross-linking reaction of the microspheres;

[0087] 5) After the reaction is over, stop heating and stirring, make the temperature of the system drop to room temperature, and pour off the upper oil phase;

[0088] 6) Add ether twice the volume of the remaining product (lower layer a...

Embodiment 2~4

[0095] The porous hydrogel microspheres of Examples 2-4 were prepared according to the corresponding added materials and amounts in Table 1 below, with the same operation steps as Example 1.

[0096] Table 1 Added materials and amounts added in Examples 2 to 4

[0097]

Embodiment 5

[0099] like figure 1 Shown:

[0100] 1) Add 0.1 g of Span 80 to 100 g of liquid paraffin (emulsifier: oily solvent = 0.1:100), stir and dissolve at 60°C to prepare an oil phase.

[0101] 2) Add 0.5g GelMA (5%), 0.2g initiator sodium persulfate (SPS) (2%) and 0.1g PEO (1%) to 10mL deionized water, heat and stir in the dark at 50°C to obtain a hydration Glue precursor solution;

[0102] 3) Add 1 mL of the precursor solution in the above step 2) to 20 mL of the oil phase prepared in step 1) and heat and stir at a speed of 500 r / min for 20 min to form a water-in-oil emulsion;

[0103] 4) heating and stirring the above-mentioned water-in-oil emulsion at 60° C. for 1 hour to cause a cross-linking reaction of the microspheres;

[0104] 5) After the reaction is over, stop heating and stirring, make the temperature of the system drop to room temperature, and pour off the upper oil phase;

[0105] 6) Add ether twice the volume of the remaining product (lower layer after removing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com