Large/medium-granularity compound pig feeds and preparation method

A pellet feed and feed technology, applied in animal feed, animal feed, application, etc., can solve problems such as foul smell, economic loss of farmers, and flies, so as to reduce feed waste, improve feed utilization rate, and reduce nutrition. The effect of excretion of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw materials of Zhongda pig compound pellet feed are (weight unit: kg): 755 corn, 50 brewer's grains, 160 soybean meal, 4.5 soybean oil, 0.3 mycocin, 1.8 calcium carbonate powder, 9.2 calcium hydrogen phosphate, 3 salt, L-lysine Hydrochloride 2.3, DL-Methionine 0.1, L-Tryptophan 0.5, Choline Chloride 0.5, 513D Pig Multidimensional 0.4, Baking Soda 1.5, Sweetener 0.5, Behe Enzyme T10 0.5, Ethoxyquinoline 0.3, 5012S Premix 10.

[0027] Preparation method of compound pellet feed for medium and large pigs:

[0028] 1) Cleaning and crushing of raw materials: After cleaning and removing impurities of all raw materials, the raw materials to be crushed, such as corn and soybean meal, are crushed to the required particle size through a 2.0mm sieve, weighed according to the formula, and then completely enter the mixer;

[0029] 2) Ingredients: Weigh the other raw material components of the formula, then pour them into the mixer and mix them completely;

[0030] 3) Conditioni...

Embodiment 2

[0036] Raw materials of Zhongda compound pig pellet feed are (weight unit: kg): corn 700, brewer's grains 60, soybean meal 180, soybean oil 5.5, mycocin 0.3, calcium carbonate powder 1.9, calcium hydrogen phosphate 10, salt 3, L-lysine Hydrochloride 2.1, DL-Methionine 0.2, L-Tryptophan 0.6, Choline Chloride 0.5, 513D Pig Multidimensional 0.5, Baking Soda 1.5, Sweetener 0.5, Behe Enzyme T10 0.5, Ethoxyquinoline 0.3, 5012S Premix 11.

[0037] The preparation method of pellet feed for medium and large pigs is the same as in Example 1.

Embodiment 3

[0039] Raw materials of compound pellet feed for Zhongda pigs are (weight unit: kg): 790 corn, 40 brewer’s grains, 140 soybean meal, 3.5 soybean oil, 0.2 mycocin, 1.7 calcium carbonate powder, 8.2 calcium hydrogen phosphate, 3 salt, L-lysine Hydrochloride 2, DL-Methionine 0.1, L-Tryptophan 0.4, Choline Chloride 0.5, 513D Pig Multidimensional 0.3, Baking Soda 1.5, Sweetener 0.5, Behe Enzyme T10 0.5, Ethoxyquinoline 0.3, 5012S Premix 9.

[0040] The preparation method of the compound pellet feed for medium and large pigs is the same as that in Example 1.

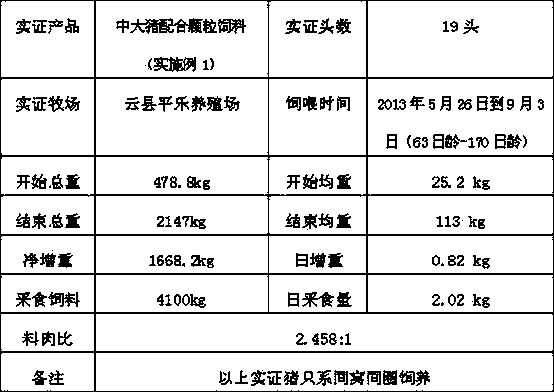

[0041]Empirical data (1):

[0042]

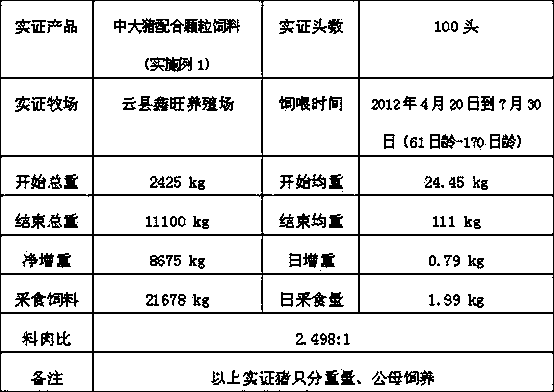

[0043] Empirical data (2):

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com