Uniformly blending back curing method for remnant flaky tobacco and application of remnant flaky tobacco

A technology of cigarettes and fractions, which is applied in the field of blending and back-curing of tobacco leaves, can solve the problems of mature practices, unseen standards and reports without the reuse of fractional cigarettes, so as to achieve homogeneity and ensure homogeneity. , to achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

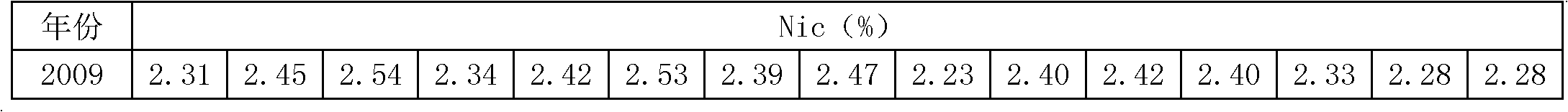

[0036] The formula plan for the uniform back-roasting of the fractional tobacco in this embodiment is as follows: according to the inventory of raw materials, it is planned to use 220000 kg of zero tobacco leaves of 164 grades such as "2009; flue-cured tobacco; Yunnan Chuxiong; laminar tobacco; C4F; The processing combination is a raw material grade, and the combined name is: 2009; flue-cured tobacco; Yunnan; sheet tobacco; C4L-09.

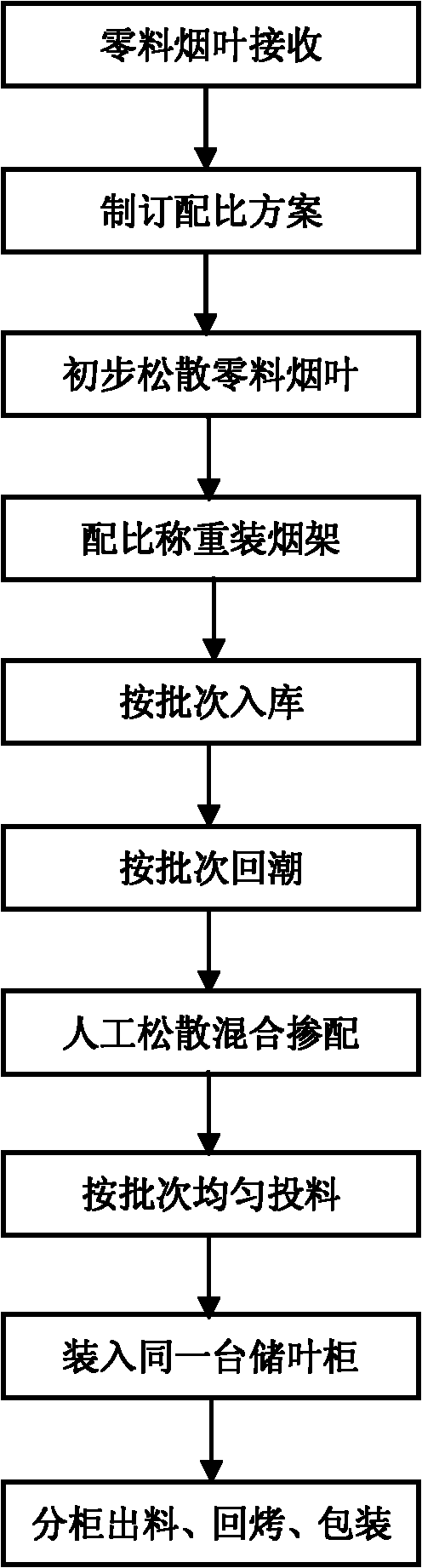

[0037] The all-fitting back-roasting method of odd piece tobacco of the present embodiment, as figure 1 shown, including the following steps:

[0038] (1) According to the total weight of 220,000 kg (220 tons) of fractional cigarettes that need to be remixed, the weights of each grade are different, and 55 processing batches are designed according to the capacity of the leaf storage cabinet (4 tons). Batches of laminar tobacco (ie weighing 4 tons) are packed into 15 containers (tobacco racks), and the weight of tobacco leaves in each container is...

Embodiment 2

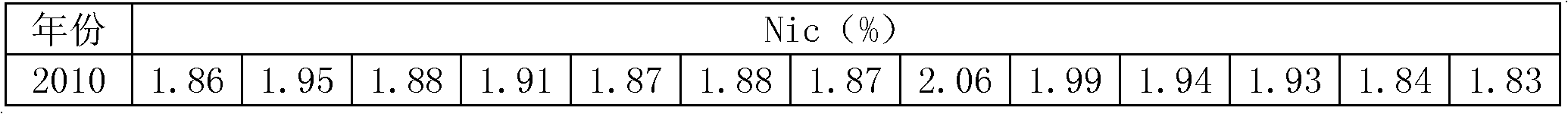

[0056] Combining 111 grades of 200,000Kg zero-material tobacco leaves from yy cigarette factory "2010; flue-cured tobacco; Fujian Sanming Ninghua; sheet tobacco; C4F-H; No. Flue-cured tobacco; Fujian; sheet tobacco; Y2L-10.

[0057] According to the method step of embodiment 1, according to the total weight of 200,000 kilograms (200 tons) of the fractional cigarettes that need to be remixed, the weights of each grade are not equal, and according to the capacity of the leaf storage cabinet (4 tons), it is designed to be 50 processing batches Once, each batch of laminar tobacco (ie weight 4 tons) is packed into 13 containers (tobacco racks), and the tobacco leaf weight of each container is about 0.308 tons, and finally obtain the fractional laminar tobacco after all matching back to roasting.

[0058] Table 3 The detection data of nicotine content in Y2L-10 finished cigarettes in 2010

[0059]

[0060] Table 4 Statistical results of nicotine content in Y2L-10 finished tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com