Anti-loosening mechanism for installing robot

An installation and anti-loosening technology, applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., can solve the problems that bolts cannot be used again, are prone to loosening, waste, etc., and achieve improved firmness, anti-vibration, and improved firmness performance and anti-loosening performance, and the effect of reducing the chance of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

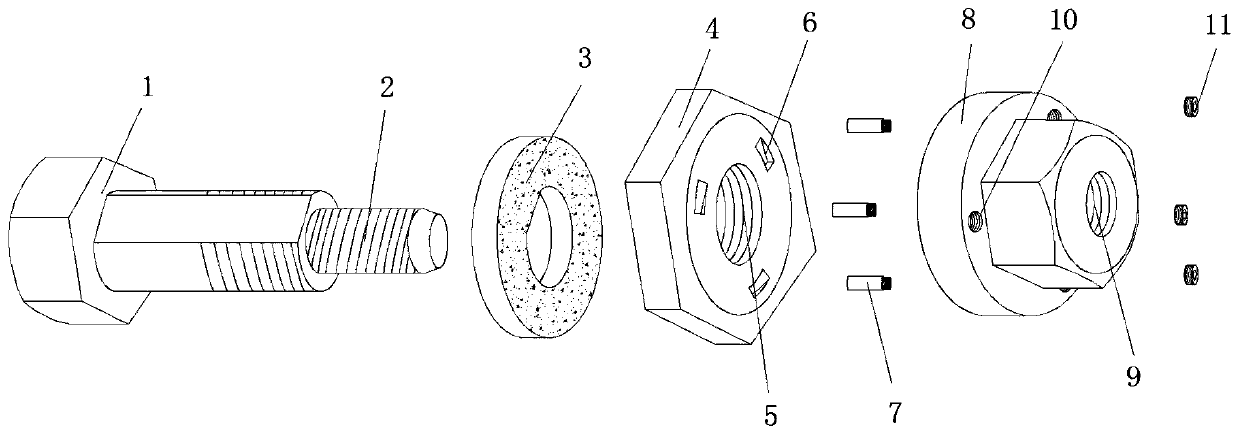

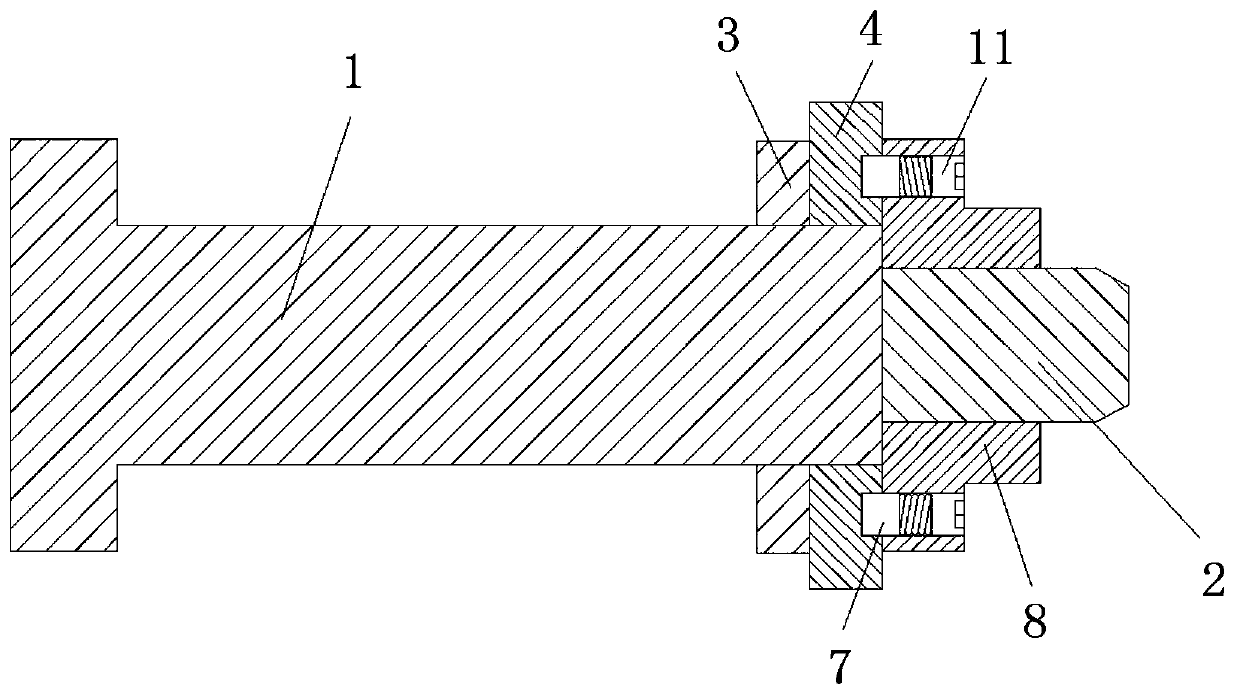

[0033] see Figure 1-5 , this embodiment provides an anti-loosening mechanism for robot installation, including a bolt rod 1 and a fastening nut 4, the axial direction of the bolt rod 1 is provided with a cut surface, and the top end of the bolt rod 1 is integrally formed with a reverse threaded rod 2. A washer 3 is sleeved on the bolt shank 1, and a through hole matching the bolt shank 1 is opened on the washer 3, and a side of the bolt shank 1 corresponding to the washer 3 is threaded with a Tightening nut 4, the middle part of described fastening nut 4 is provided with the first threaded hole 5, and described fastening nut 4 is provided with arc-shaped groove 6 around corresponding described first threaded hole 5, and described reverse thread The side of the outer wall of the rod 2 corresponding to the fastening nut 4 is threaded with a limit nut 8, and the middle part of the limit nut 8 is provided with a second threaded hole 9, and the limit nut 8 corresponds to the first...

Embodiment 2

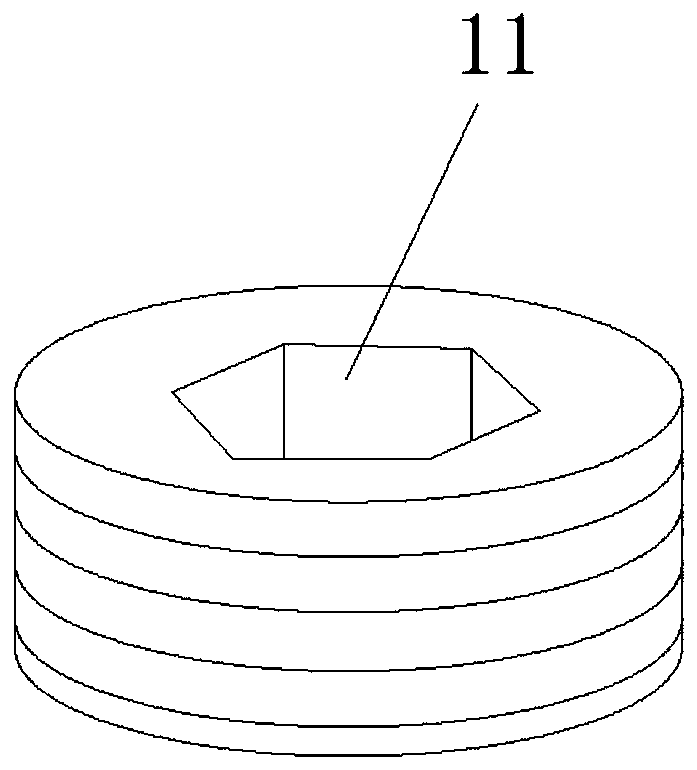

[0036] see Figure 1-5 , On the basis of Example 1, a further improvement is made: the thread direction of the bolt shank 1 is opposite to that of the reverse threaded rod 2, and the cross-sectional diameter of the bolt shank 1 is larger than that of the reverse threaded rod 2 The diameter of the cross-section is 4mm larger, which is convenient for the installation and disassembly of the fastening nut 4. The first threaded hole 5 matches the bolt rod 1, and the second threaded hole 9 matches the reverse threaded rod 2. To facilitate the installation and disassembly of the fastening nut 4 and the bolt rod 1, the installation and disassembly of the limit nut 8 and the reverse thread rod 2, the direction of the arc groove 6 from shallow to deep is consistent with the thread direction of the reverse thread rod 2 On the contrary, to facilitate the rotation and tightening of the fixing pin 701 is not affected, the upper end of the inner side wall of the fixing hole 10 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com