Anti-loosening fastening assembly for bolts

An anti-loosening and bolt technology, applied in the direction of threaded fasteners, locking fasteners, bolts, etc., can solve the problems of complicated loading and unloading, waste, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation

[0011] The interlocking anti-loosening bolt of the present invention will be further described in detail in conjunction with the accompanying drawings to realize the anti-loosening function

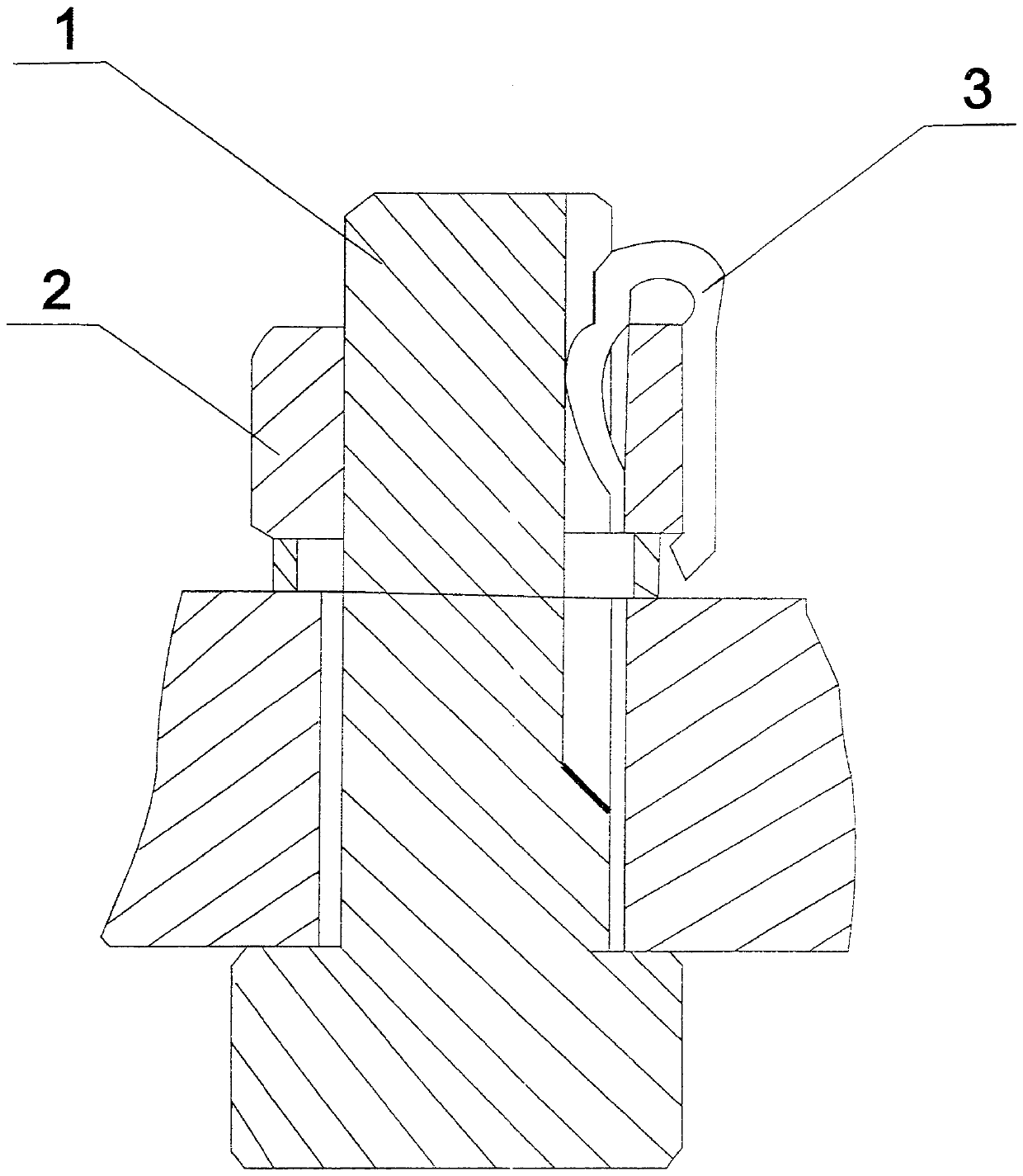

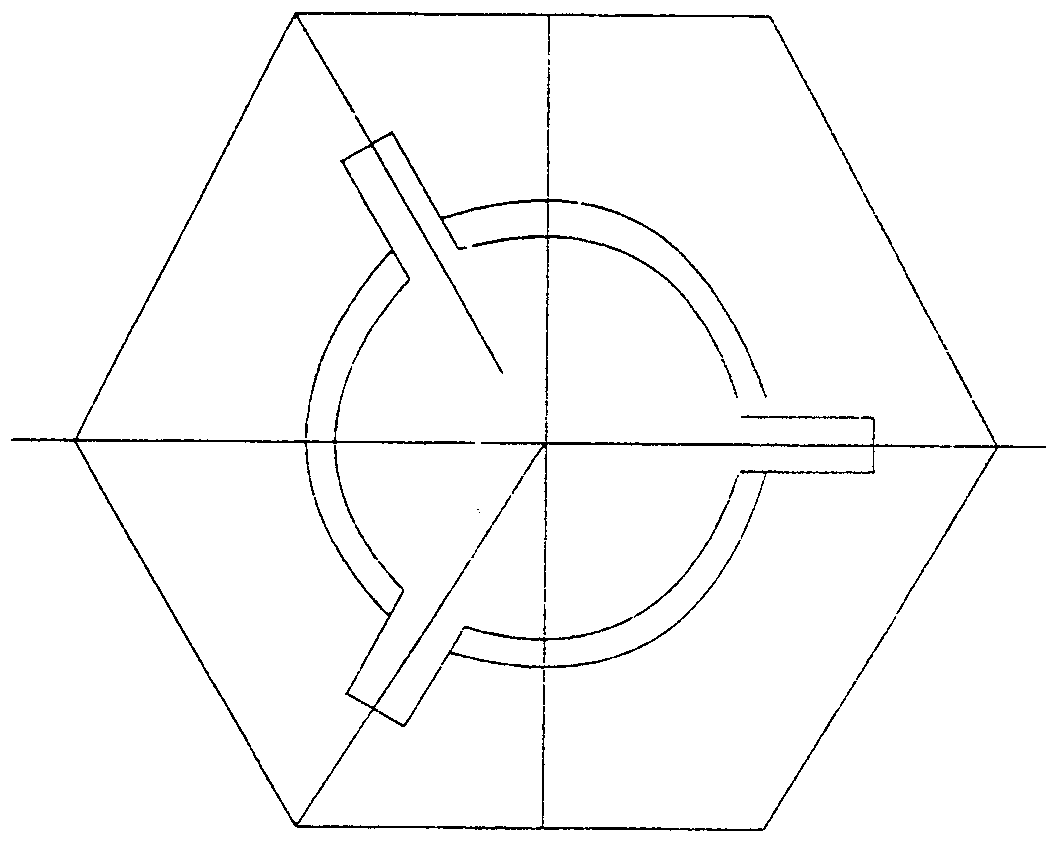

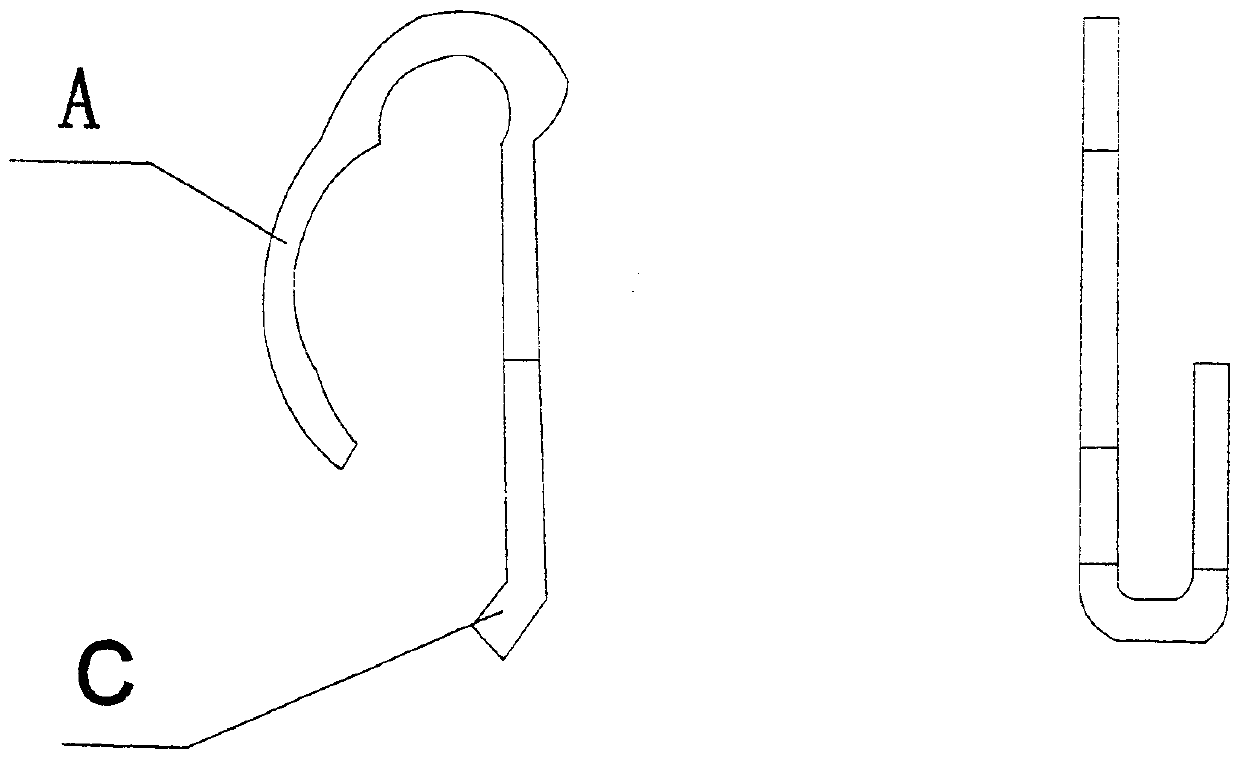

[0012] Such as figure 1 As shown, the interlocking anti-loosening bolt assembly of the present invention consists of a slotted nut, a slotted screw, an elastic backstop hook and a common spring washer. The shape of the elastic anti-retraction hook in static state is as follows: image 3 As shown, it is made of ordinary spring material through mechanical processing, and then it is qualitatively formed by heat treatment. The nut is slotted at 120° inside the hexagon of the original shape with an ordinary nut, such as figure 2 shown. The screw uses an ordinary screw to open a vertical slot in the thread part, such as Figure 4 shown. The spring washer is an ordinary spring washer.

[0013] When the nut is pressed tightly, the elastic anti-retraction h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com