Fallen leaf sweeping equipment integrating automatic sweeping, smashing and extrusion forming and capable of being used with motor vehicle

A technology of extrusion molding and cleaning equipment, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of inability to realize resource reuse, untimely, time-consuming and laborious cleaning, etc., to achieve waste recycling and reduce environmental pollution. , the effect of liberating manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

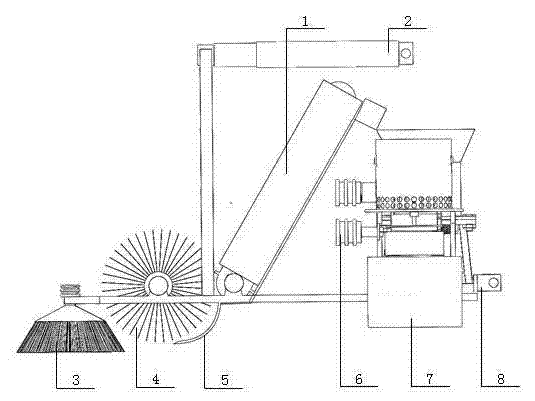

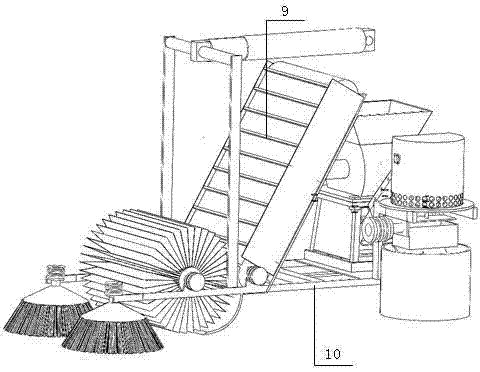

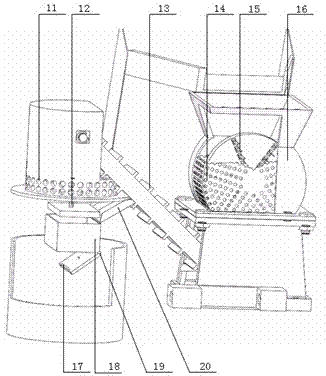

[0021] see figure 1 , figure 2 and image 3 , a leaf cleaning equipment that integrates automatic cleaning, crushing, bonding and extrusion molding and can be used with motor vehicles (tractors), gasoline engines, etc. Including inward cleaning sweeping roller 3, ascending sweeping roller 4, scraper type conveyor belt 1, bonding extrusion molding device 11 and crushing bin 16, etc., the inward cleaning sweeping roller 3 collects fallen leaves in front of the equipment and on both sides The middle position of the two sweeping rollers, the ascending sweeping roller 4 is connected tangentially to the scraper conveyor belt 1, the end of the scraper conveyor belt 1 is connected to the entrance of the crushing bin 16, and the outlet of the crushing bin is connected to the adhesive extrusion Forming device 11.

[0022] In order to realize efficient cleaning operation, the ascending sweeping roller 4 utilizes the counterclockwise rotation roller to convey the collected fallen leav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com