Radial friction welding process method for connecting austenitic alloy steel and non-magnetic drill collar

A non-magnetic drill collar and friction welding technology, applied in welding equipment, metal processing equipment, applications, etc., can solve problems such as low production efficiency, high cost, and difficult repair of failed drill collars, and achieve the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

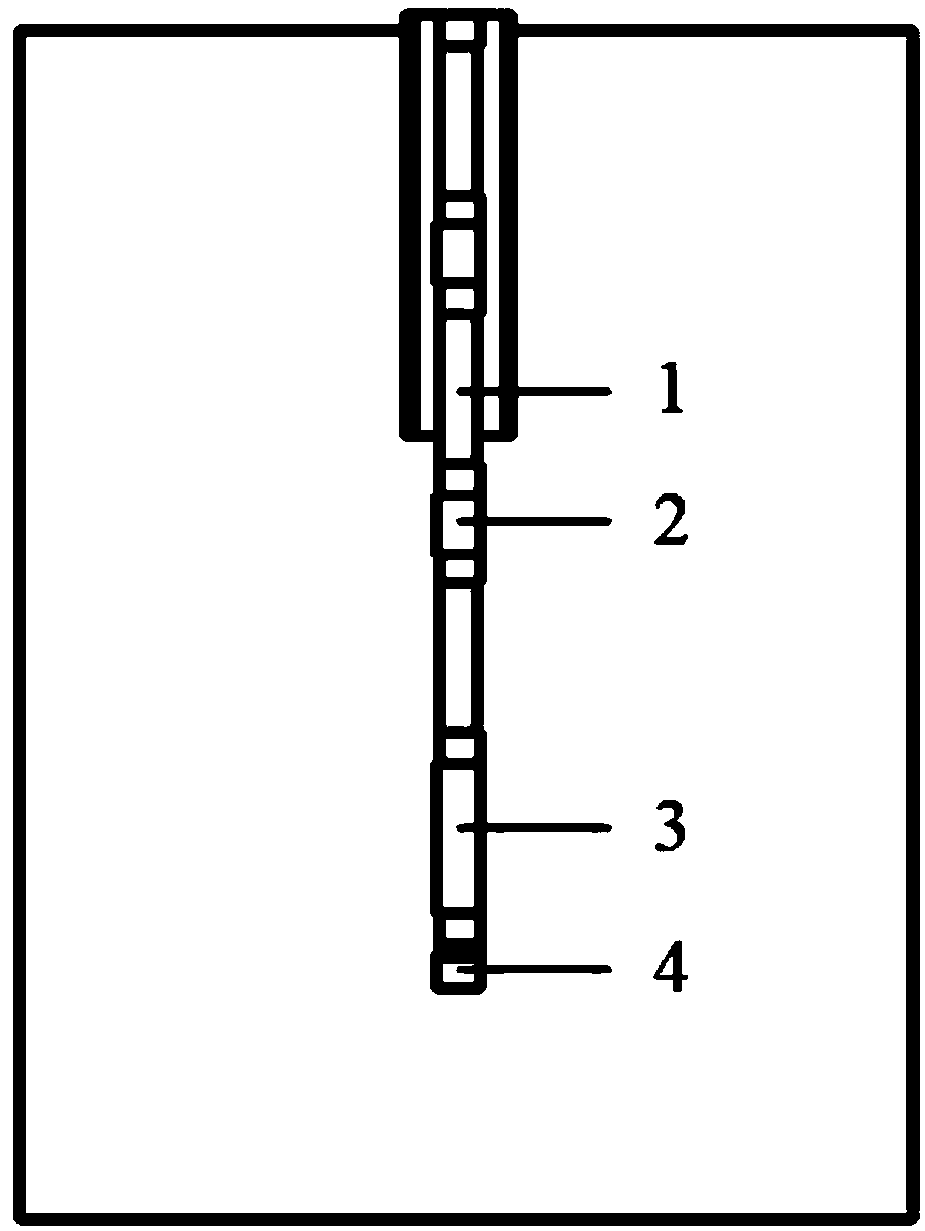

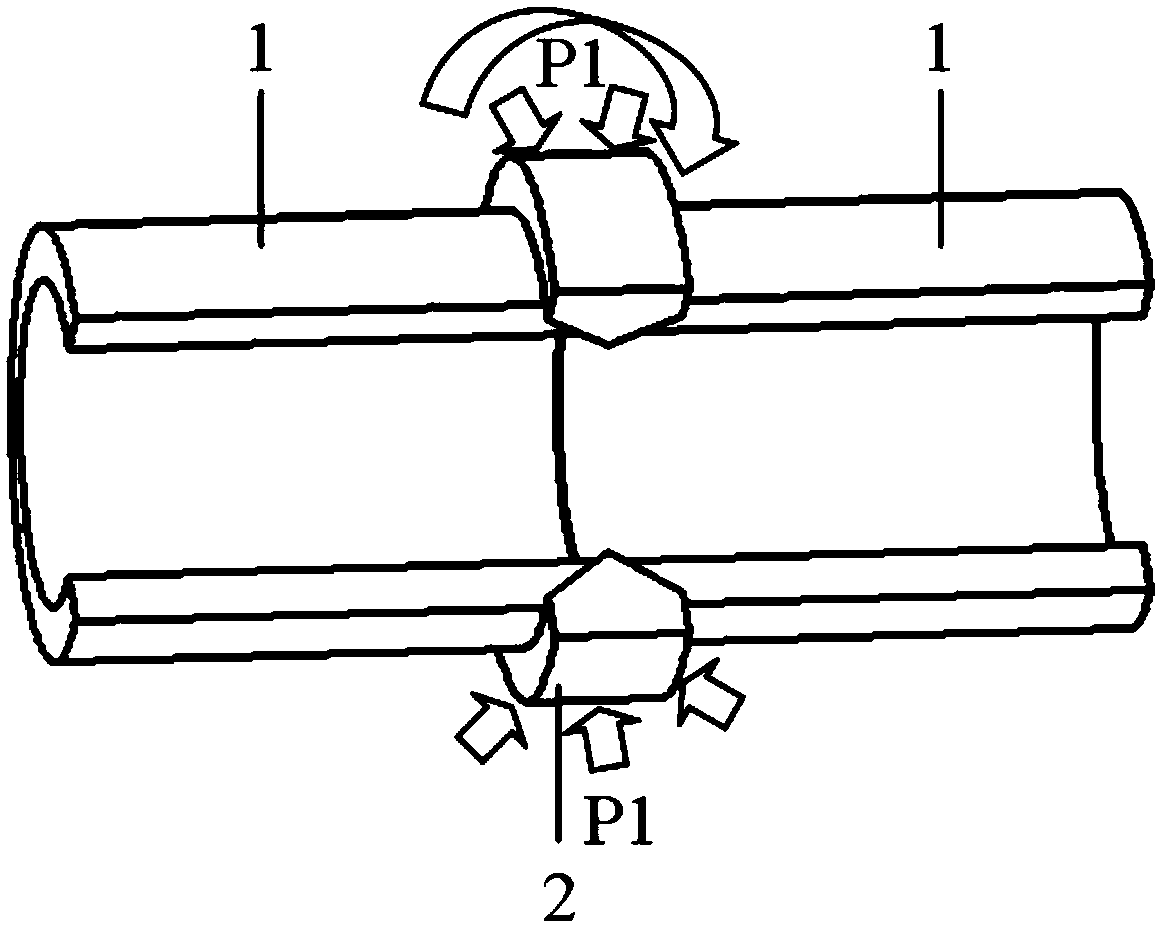

[0069] like Figure 2-5 As shown, a method for preparing non-magnetic drill collars by continuous drive radial friction welding comprises the following steps:

[0070] (1) Welding interface treatment: Austenitic alloy steel (composition as shown in Table 1) is made into a workpiece with an outer diameter of φ104.8mm, a wall thickness of δ=20mm, and a length of 300mm, and such as Figure 5 The radial ring shown, where the pipe end surface bevel angle α = 30°, such as Figure 4 As shown, the sharp angle at the front end of the radial ring is the same as the V-shaped groove and completely coincides with the groove. The specific dimensions of the radial ring used are x=30mm, y=10mm, z=20mm. Use sandpaper to clean the surface of the workpiece to be welded. At the same time, use alcohol and acetone to remove oil stains on the interface to be welded;

[0071] (2) Weldment clamping: the workpiece 1 and radial ring 2 in step (1) are clamped into the pipe body fixture in the HSMZ-130 ...

Embodiment 2

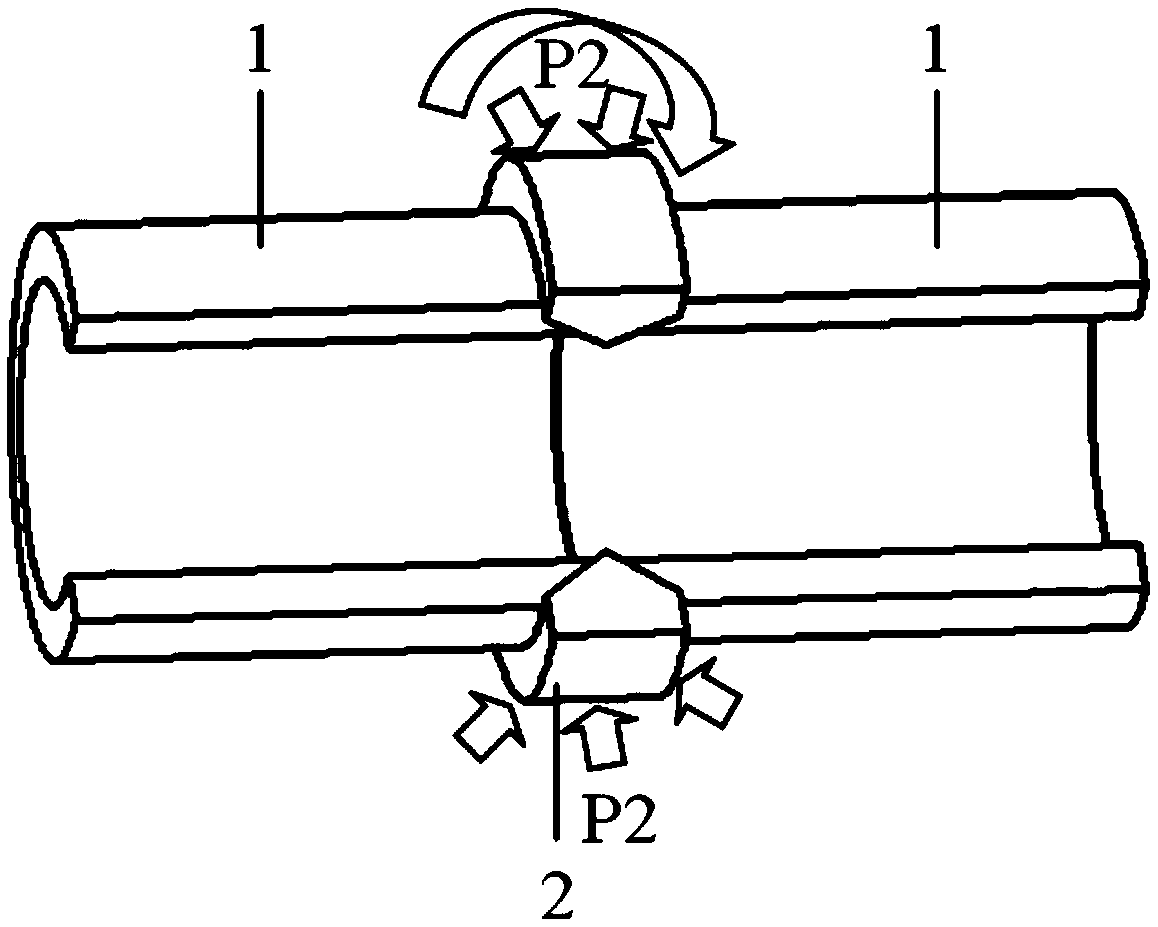

[0074] like Figure 2-5 As shown, a method for preparing non-magnetic drill collars by inertial radial friction welding, the main difference between it and the continuous drive radial friction welding process is that the driving device stops the flywheel and radial ring after the flywheel and radial ring reach a predetermined speed. Driven to the ring, using the flywheel and the inertial rotation of the radial ring to achieve friction welding. The method comprises the steps of:

[0075] (1) Welding interface treatment: Austenitic alloy steel (composition shown in Table 1) is made into a workpiece with a specification of φ228.6mm, a wall thickness of δ80mm, and a length of 300mm. Figure 5 The radial ring shown, where the pipe end surface bevel angle α = 30°, such as Figure 4As shown, the sharp angle at the front end of the radial ring is the same as the V-shaped groove and completely coincides with the groove. The specific dimensions of the radial ring used are x=50mm, y=20...

Embodiment 3

[0079] The preparation method is the same as in Example 1, except that the spindle speed is 2500 rad / min, the friction pressure is 50 MPa, the friction time is 15 s, the upsetting pressure is 600 MPa, and the holding time is 15 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com