Method for comprehensively treating and recycling stacked rubbish

A comprehensive management and resource utilization technology, applied in application, fertilizer mixture, organic fertilizer preparation, etc., can solve the problems of complex equipment, low efficiency, large quantity, etc., and achieve high nutrient content, improved fermentation effect, and high organic matter content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

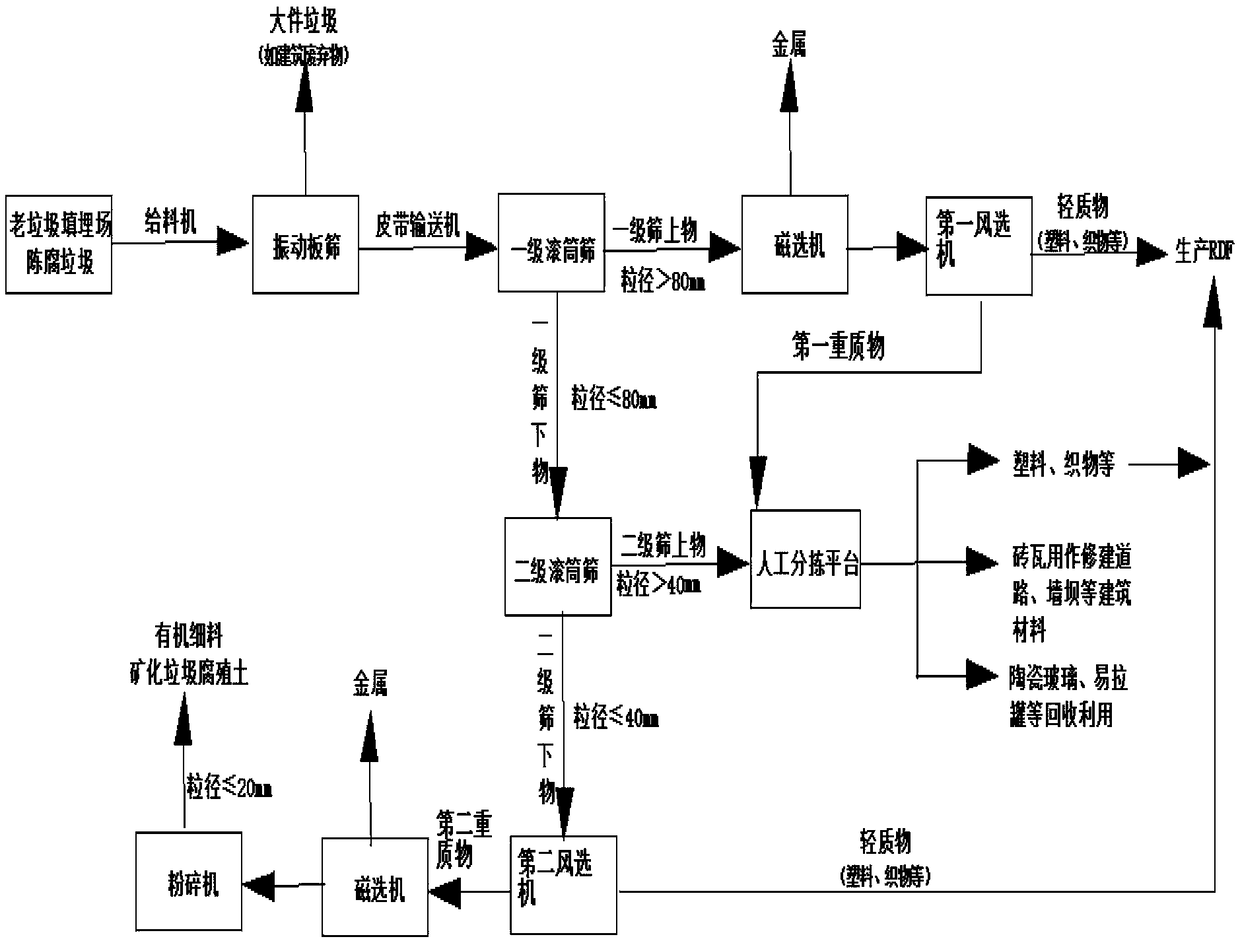

[0053] For the method of comprehensive treatment and resource utilization of stock garbage in this embodiment, please refer to figure 1 and figure 2 shown, including the following steps:

[0054] 1) Garbage excavation: The stabilized old landfill is excavated in a partitioned and layered manner;

[0055] 2) Convey the excavated mineralized waste to the vibrating plate screen through the feeder to remove the bulky waste, where the bulky waste includes building waste or large waste wood and other relatively large sizes The waste and old items then enter the first-stage drum screen, and the first-stage sieve, the part with a particle size > 80mm, then passes through the first magnetic separation equipment to magnetically screen out the metal substances doped in the material, and then enters the first wind separator The light materials such as plastics and fabrics obtained by winnowing are used to produce RDF, and the heavy materials enter the manual sorting platform to further...

Embodiment 2

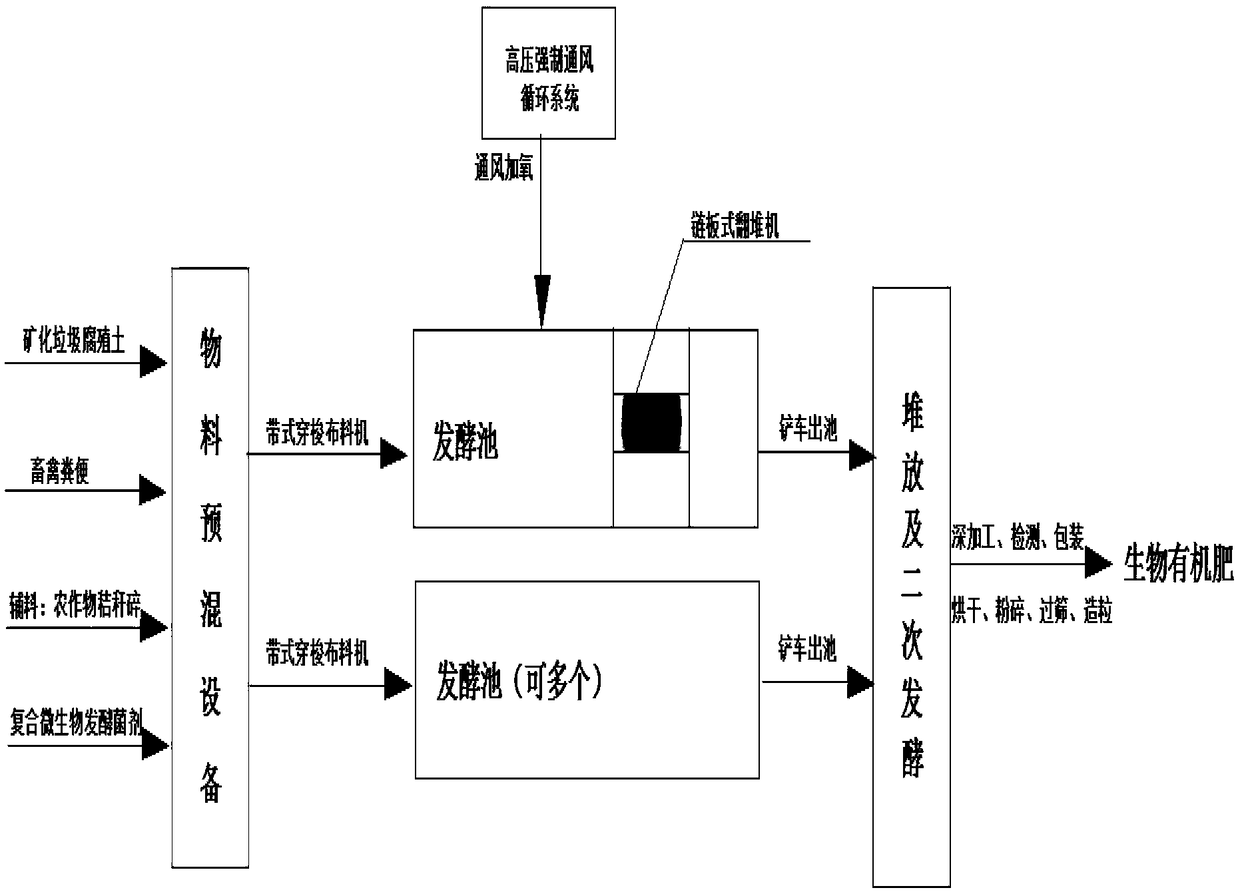

[0070] The method for the comprehensive management and resource utilization of the stock garbage of this embodiment is basically the same as that of Embodiment 1, only the difference is: please refer to figure 1 and figure 2 As shown, the process flow of bio-organic fertilizer preparation from mineralized waste humus organic fine material is as follows:

[0071] A. Send the above-mentioned secondary sieve under matter mineralized garbage humus organic fine material, livestock and poultry manure, auxiliary materials, and composite microbial fermentation bacterial agent into the mixing mixer in specified weight parts, and stir and mix to make it uniform , to obtain mixed fermented material.

[0072] The raw material ratio is 25 parts by weight of mineralized waste humus, 25 parts by weight of livestock and poultry manure, 10 parts by weight of auxiliary materials, and 3 parts by weight of composite microbial fermentation agent;

[0073] The moisture content of the mixed ferme...

Embodiment 3

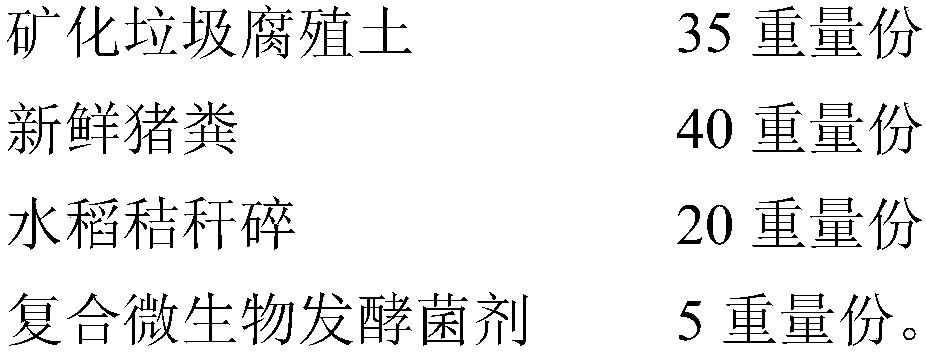

[0087] The method for the comprehensive management and resource utilization of the stock garbage of this embodiment is basically the same as that of Embodiment 1, only the difference is: please refer to figure 1 and figure 2 As shown, the process flow of bio-organic fertilizer preparation from mineralized waste humus organic fine material is as follows:

[0088] A. Send the above-mentioned secondary sieve under matter mineralized garbage humus organic fine material, livestock and poultry manure, auxiliary materials, and composite microbial fermentation bacterial agent into the mixing mixer in specified weight parts, and stir and mix to make it uniform , to obtain mixed fermented material.

[0089] The raw material ratio is 40 parts by weight of mineralized waste humus, 40 parts by weight of livestock and poultry manure, 25 parts by weight of auxiliary materials, and 8 parts by weight of composite microbial fermentation agent;

[0090] The moisture content of the mixed ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com