Combined cutter moving type numerically controlled lathe

A CNC lathe and composite technology, applied in the field of CNC lathes, can solve the problems of increasing the labor intensity of the staff, affecting the drilling speed of the workpiece, reducing the processing efficiency of the workpiece, etc., so as to improve the drilling speed, reduce the labor intensity, and improve the processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

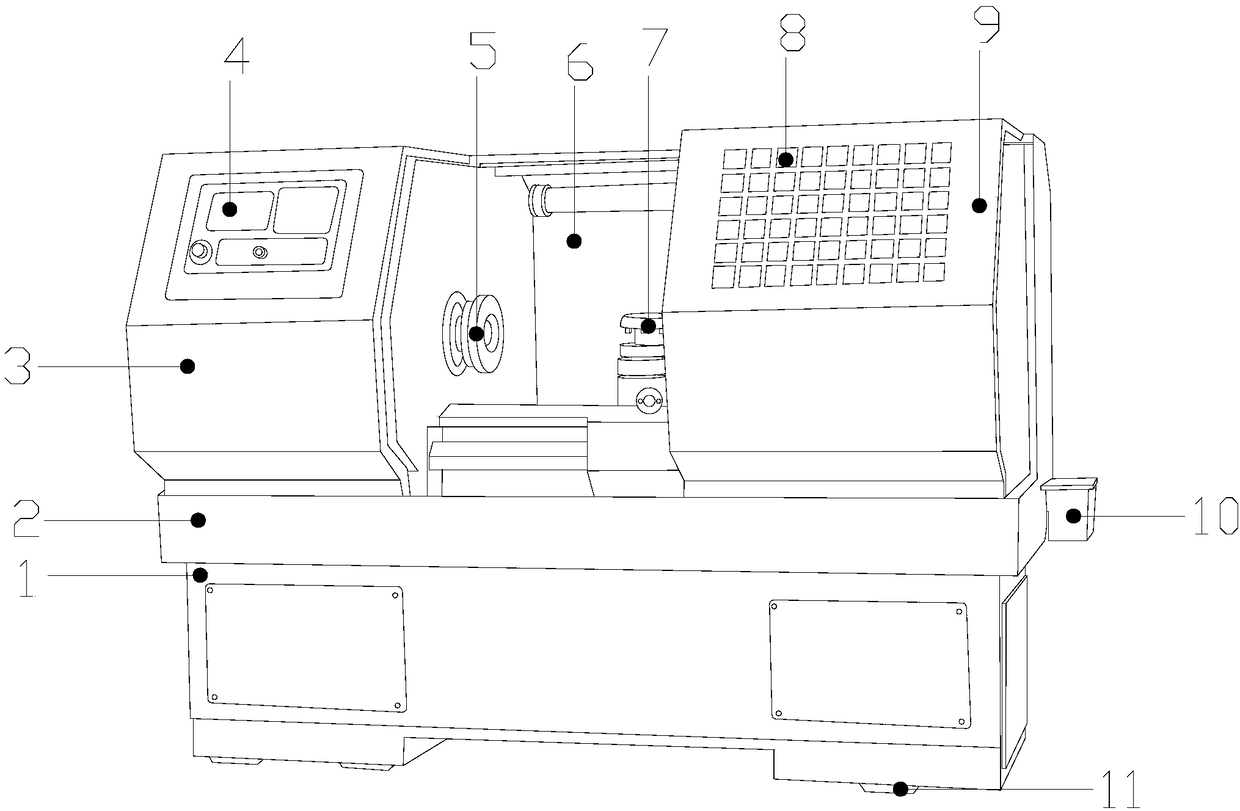

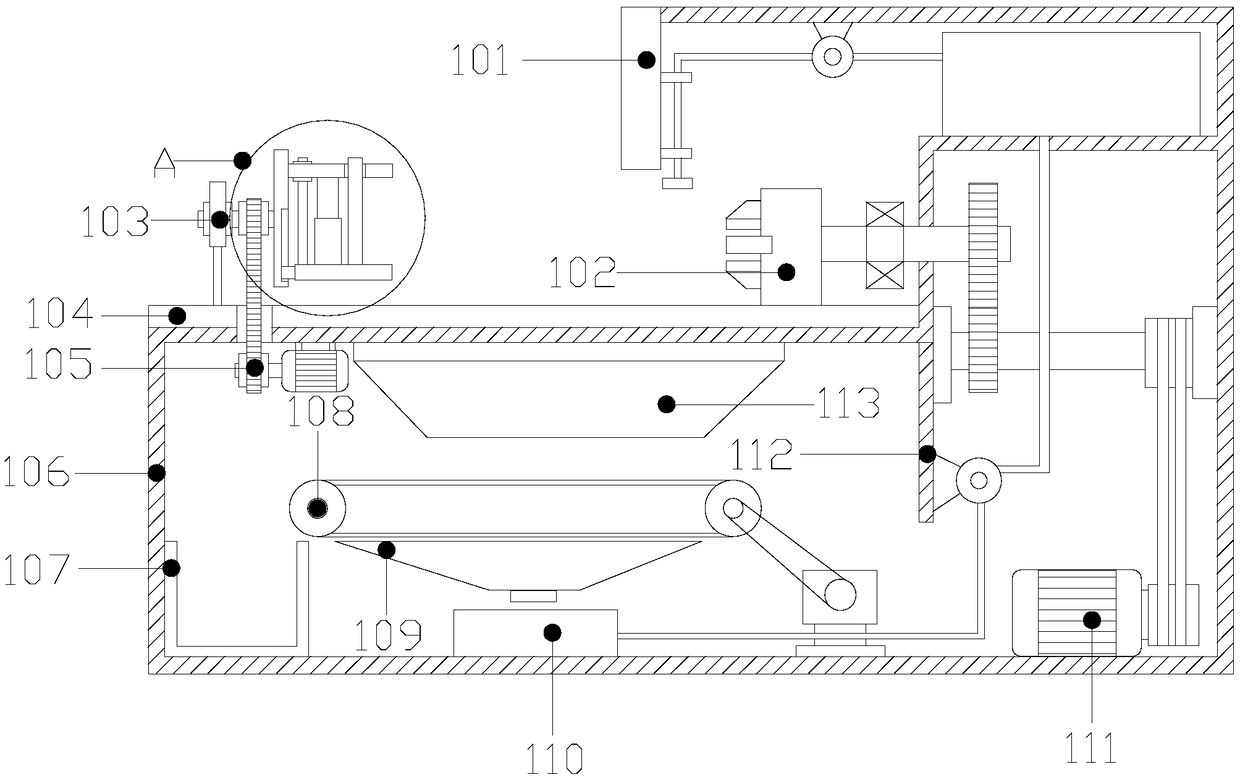

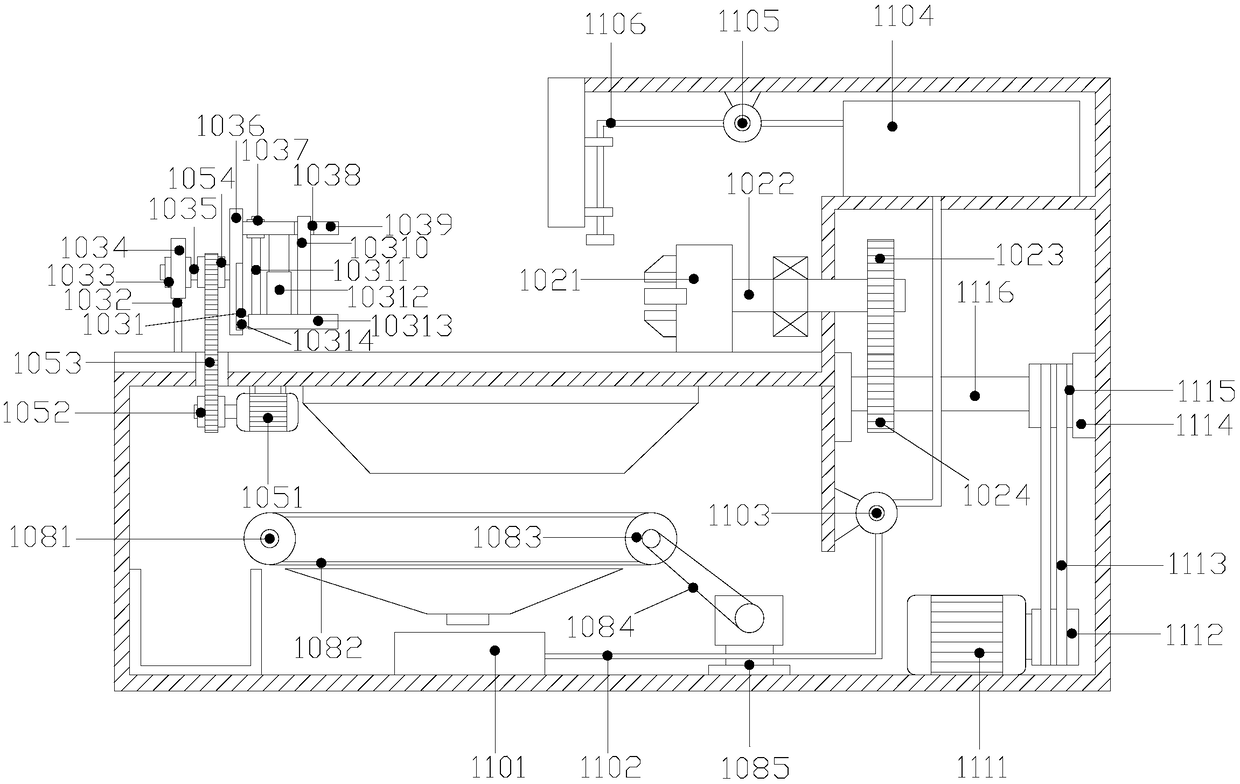

[0022] Such as Figure 1-Figure 5 As shown, the present invention provides a compound type CNC lathe, the structure of which includes an automatic positioning mechanism 1 for processing, an art line 2, an electric control cabinet 3, a control panel 4, a turntable 5, a processing box 6, a processing table 7, Observation port 8, protective door 9, lubricating oil pump 10, fixed feet 11, said fixed feet 11 are provided with more than two and are evenly welded to the bottom of the automatic positioning mechanism 1 for processing, and the automatic positioning mechanism 1 for processing is connected with the artist The lines 2 are all rectangular structures, the left side of the processing box 6 is fixed with an electric control cabinet 3 and the two are welded together, and the bottom of the processing table 7 is fixedly welded to the inside of the processing box 6 and fixedly connected by positioning pins. The protective door 9 is fixedly fastened and installed on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com