Impregnating equipment for producing high-temperature-resisting thermoplasticity composite material unidirectional prepreg tape

A unidirectional prepreg tape and composite material technology is applied in the field of impregnation equipment for producing high temperature resistant thermoplastic composite material unidirectional prepreg tape, which can solve the problems of difficulty in controlling the amount of powder and the stability of the amount of powder, and achieve resin Uniform and stable content, promotion of hot-melt effect, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

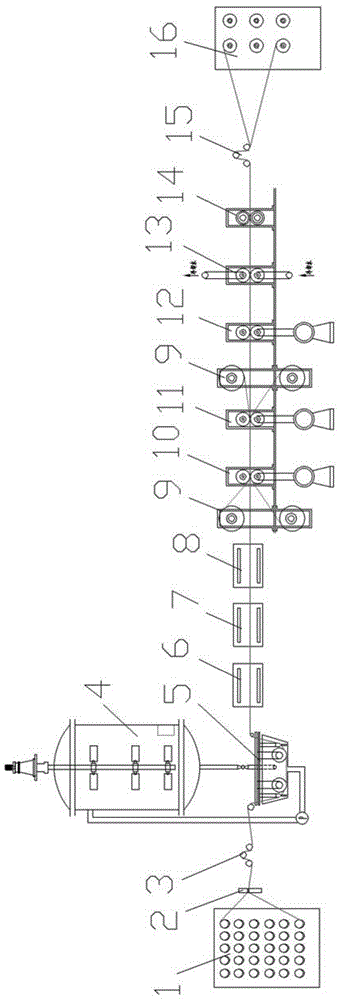

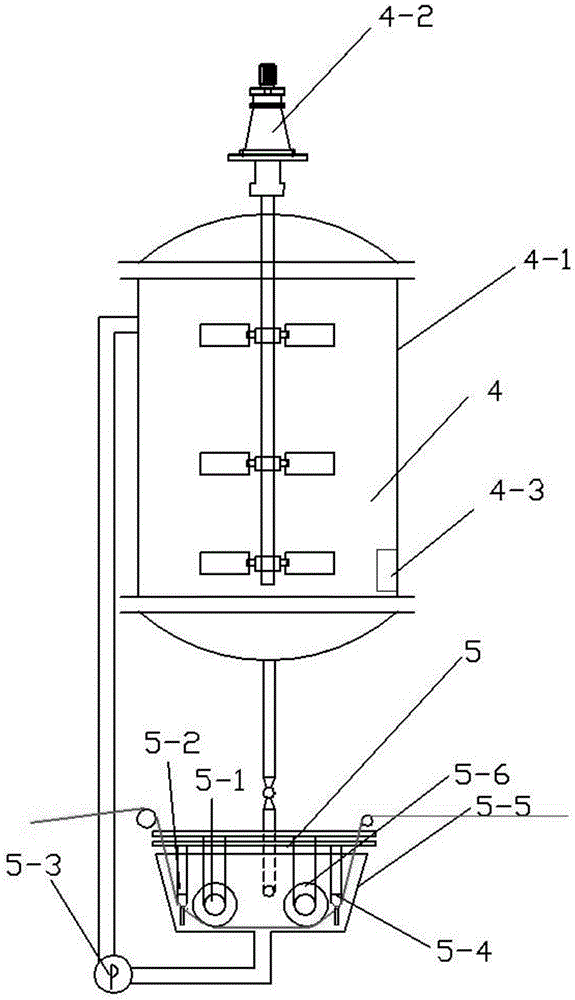

[0025] Such as figure 1 and figure 2As shown, a kind of dipping equipment for producing high-temperature-resistant thermoplastic composite material unidirectional prepreg tape according to the present invention includes a yarn unwinding device 1, a yarn beam hole plate 2, a yarn spreading device 3, a slurry impregnation device, and a pre-drying device , separator unwinding and rewinding device 9, hot-melt dipping device, sizing device 12, cooling and calendering device 13, slitting device 14, tension detection device 15 and spiral rewinding device 16, the yarn unwinding device 1, display Yarn device 3, slurry impregnation device, pre-drying device, separator unwinding and winding device 9, hot-melt impregnation device, setting device 12, cooling and calendering device 13, cutting device 14, tension detection device 15 and spiral winding device Roll device 16 is installed in sequence, wherein: Yarn unwinding device 1: is made up of creel and bobbin roller; Yarn bobbin roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com