Method for packaging flexible package cell

A technology for flexible packaging batteries and packaging methods, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, and climate sustainability. Avoid bad appearance, good hot-melt effect, good heat-sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

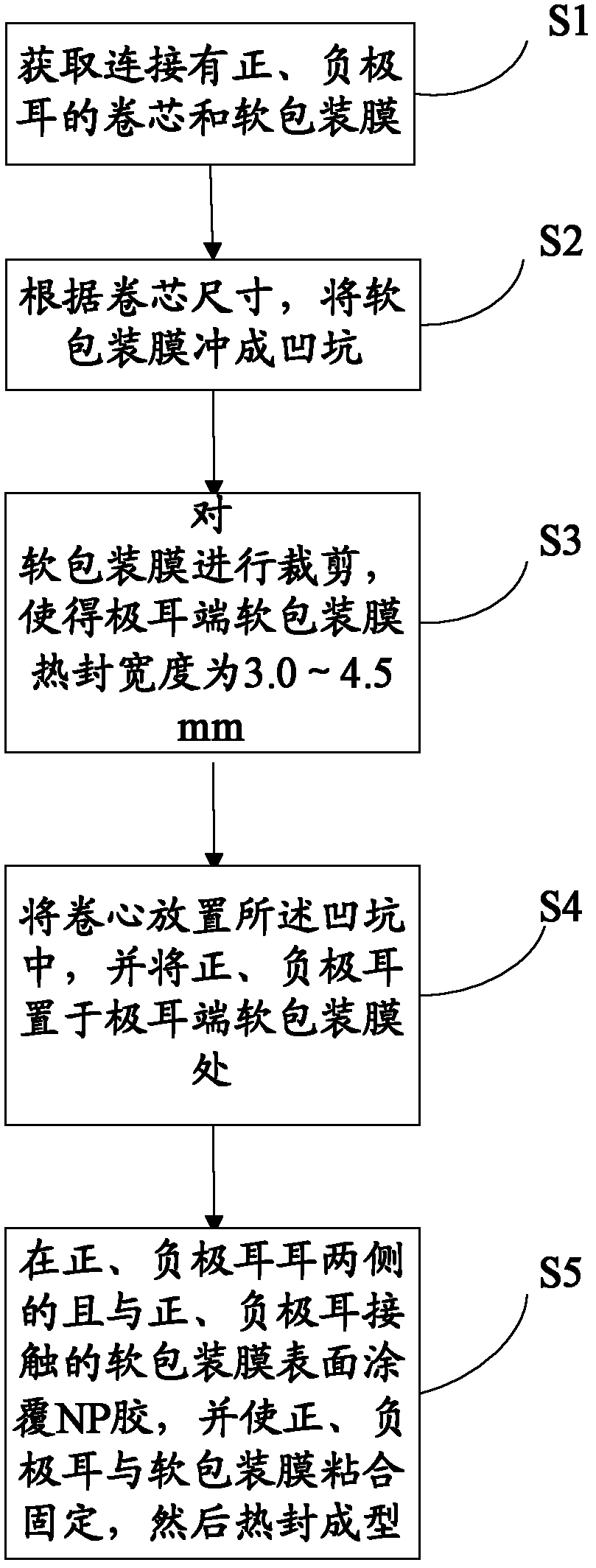

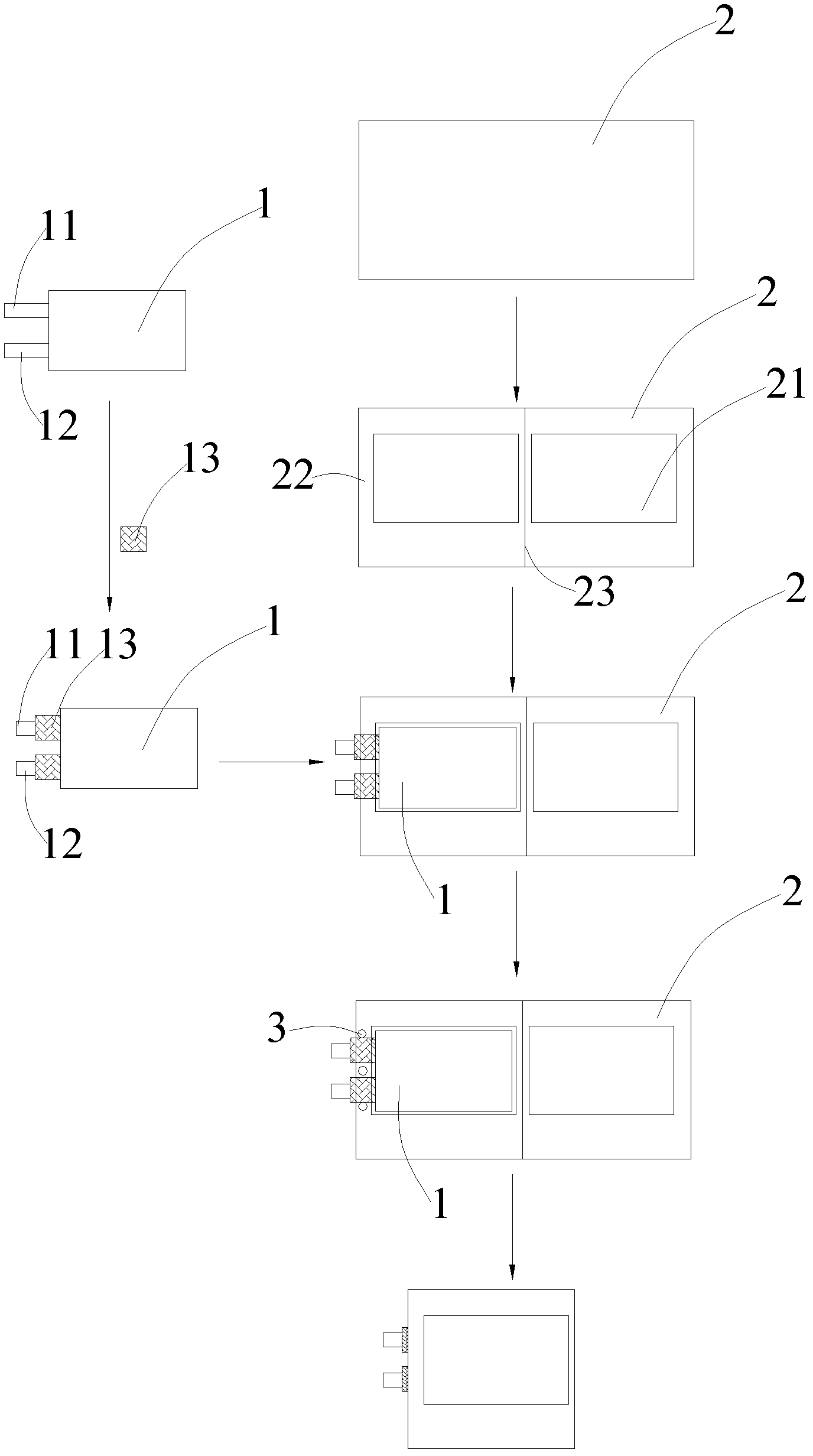

[0034] A method for encapsulating soft-packaged batteries, such as figure 2 shown, including the following steps:

[0035] Step S11: Obtain the winding core 1 connected with the positive tab 11 and the negative tab 12, the tab insulating rubber sleeve 13 and the aluminum-plastic film 2; wherein, the length of the aluminum-plastic film 2 is twice the height of the core;

[0036] Step S12: according to the size of the winding core 1, punch two identical pits 21 on the same surface of the aluminum-plastic film 2, and the two pits 21 should be symmetrical along the folding line 23;

[0037] Step S13: Cut the flexible packaging film 2 punched with the pit 21 so that the heat-sealing width of the flexible packaging film 22 at the tab end is 3.0 mm;

[0038] Step S14: The tab insulating rubber sleeve 13 is respectively sleeved on the positive pole tab 11 and the negative pole tab 12, and then heat-sealed so that the insulating rubber sleeve 13 is respectively bonded and sealed to t...

Embodiment 2

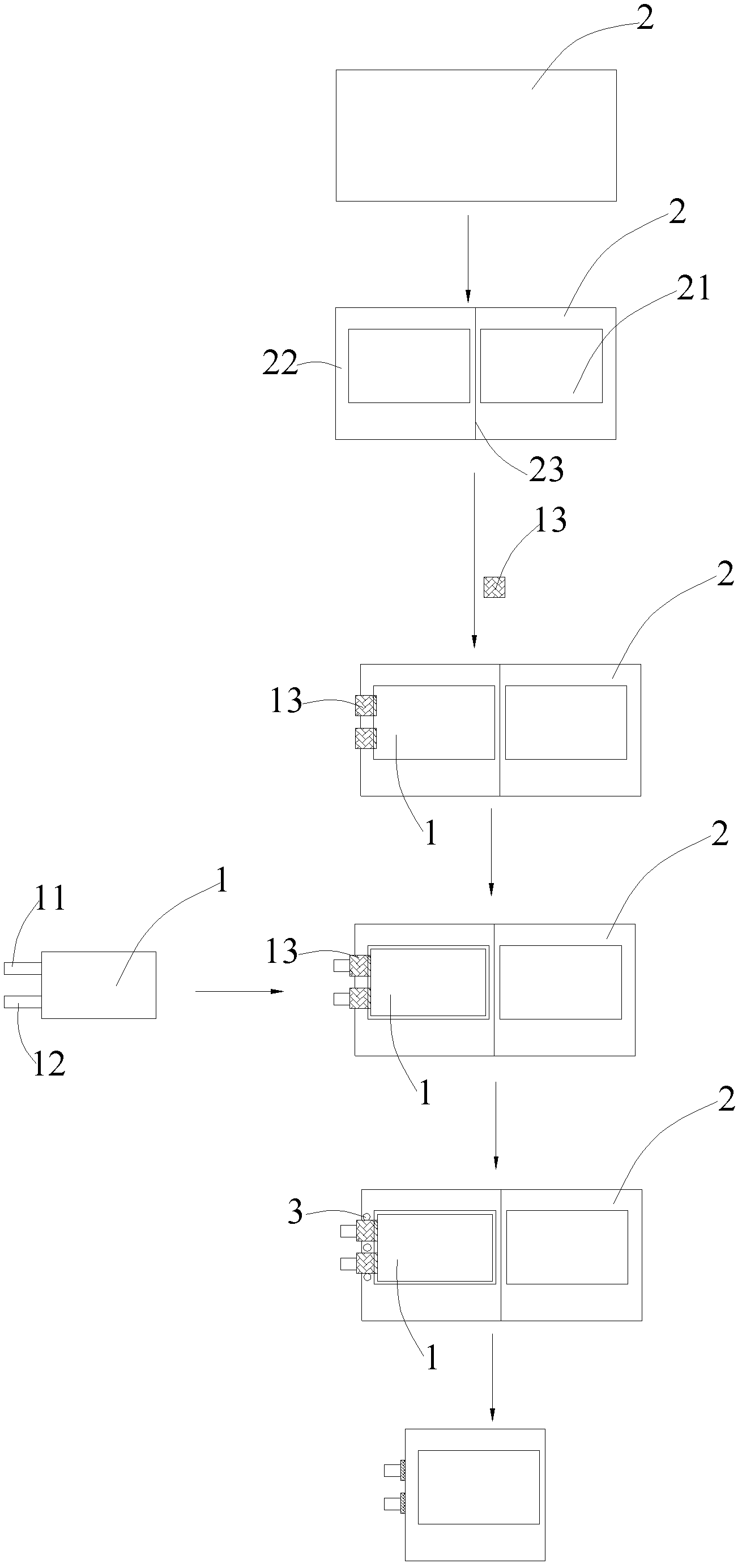

[0041] A method for encapsulating soft-packaged batteries, such as image 3 shown, including the following steps:

[0042] Step S21: Obtain the winding core 1 connected with the positive tab 11 and the negative tab 12, the tab insulating rubber sleeve 13 and the aluminum-plastic film 2; wherein, the length of the aluminum-plastic film 2 is twice the height of the core;

[0043]Step S22: According to the size of the winding core 1, punch two identical pits 21 on the same surface of the aluminum-plastic film 2, and the two pits 21 should be symmetrical along the folding line 23;

[0044] Step S23: Cut the flexible packaging film 2 punched with the pit 21 so that the heat-sealing width of the flexible packaging film 22 at the tab end is 4.5 mm;

[0045] Step S24: Paste the tab insulating rubber sleeves 13 corresponding to the number of positive tabs 11 and negative tabs 12 on the flexible packaging film with a heat-sealing width of 3.0-4.5 mm, that is, the flexible packaging fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com