Steel framework enhancement composite pipe material bearing inserting and welding method

An enhanced composite and socket welding technology, applied in the direction of pipeline connection layout, pipe/pipe joints/pipe fittings, mechanical equipment, etc. Simple, manpower and equipment reduction, good pipe sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Take welding DN250*12 pipe as an example.

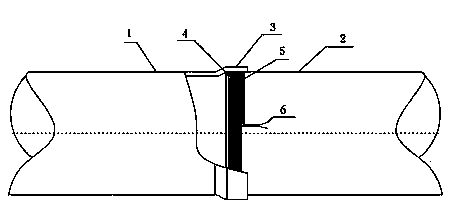

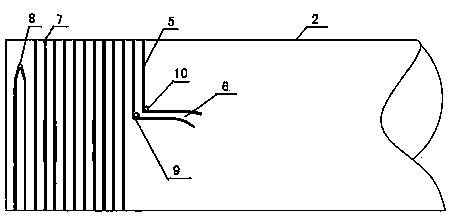

[0032] 2. The present invention as figure 1 , figure 2 Shown, a kind of steel frame reinforced composite pipe socket welding method, the method comprises the following steps:

[0033] 1) Flaring:

[0034] ①A heater is used to heat the socket at one end of the first pipe, the heating current is 23.6A, and the melting time is 60 seconds;

[0035] ②When the reinforced layer steel skeleton reaches the set temperature, move the first pipe to the flaring machine, start the hydraulic device of the flaring machine to squeeze the socket section of the first pipe, and flaring to its inner diameter and the set The outer diameter of the second pipe material of the socket matches the size;

[0036] ③ After the flaring is completed, close the hydraulic device, cool for 10 minutes, and complete the flaring operation of the socket;

[0037] 2) Grooving

[0038] ①Return the rotating arm on the slotted thread distribution machine to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com